Catalytic system for synthesizing alpha-hydroxy ketone by alkynol hydration reaction

A catalytic system, acetylenic alcohol hydration technology, applied in the direction of organic compound/hydride/coordination complex catalyst, carbon-carbon triple bond hydration preparation, physical/chemical process catalyst, etc., can solve rearrangement and other problems, and achieve high Catalytic activity, easy synthesis and recovery, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1. Catalyzing the hydration reaction of 2-methyl-3-butyn-2-ol to generate 3-hydroxyl-3-methyl-2-butanone

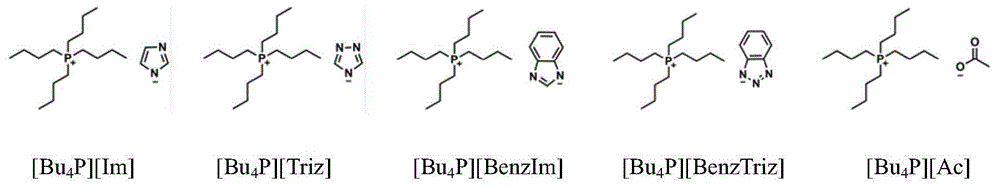

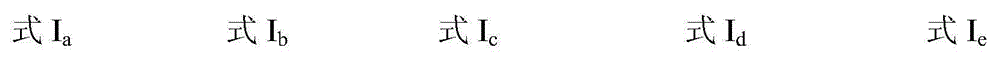

[0024] In a 250 ml single-necked bottle, 2-methyl-3-butyn-2-ol (8.41 g, 0.1 mol), H 2 O (3.60g, 0.2mol) and formula I a [Bu 4 P][Im] (97.89g, 0.3mol), with CO 2 displace the air therein; then keep the CO 2 The pressure was 0.1MPa, refluxed and stirred at 80°C for 24 hours. After the reaction is finished, with tert-butanol as internal standard, by 1 H NMR quantitative detection, using the conventional internal standard method for calculation, the yield of 3-hydroxy-3-methyl-2-butanone was 90%.

[0025] reaction product 1 H and 13 C nuclear magnetic spectrum to determine its structure:

[0026] 1 H NMR (DMSO-d6, 400 MHz) δ 5.21 (s, 1H), 2.15 (s, 3H), 1.17 (s, 6H).

[0027] 13 C NMR (DMSO-d 6 , 100MHz) δ213.64, 75.76, 26.15, 24.11.

[0028] It can be seen from the above that the product has a correct structure and is 3-hydroxy-3-methyl-2-butanone....

Embodiment 2

[0029] Example 2, catalyzing the hydration reaction of 2-methyl-3-butyn-2-ol to generate 3-hydroxyl-3-methyl-2-butanone

[0030] Adopt exactly the same reaction condition and detection method as embodiment 1, only [Bu 4 The amount of P][Im] was changed to 163.15g (0.5mol), and the yield of 3-hydroxyl-3-methyl-2-butanone was 88%.

Embodiment 3

[0031] Example 3, catalyzing the hydration reaction of 2-methyl-3-butyn-2-ol to generate 3-hydroxy-3-methyl-2-butanone

[0032] Adopt exactly the same reaction condition and detection method as embodiment 1, only [Bu 4 P][Im] amount is changed into 65.26g (0.2mol), CO 2 The gas pressure was changed to 1 MPa, the reaction time was changed to 24 h, and the yield of 3-hydroxy-3-methyl-2-butanone was 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com