Microwave hydrolysis device

A hydrolysis equipment and microwave technology, which is applied in the field of hydrolysis equipment heated by microwave irradiation, can solve the problems of long hydrolysis time, environmental pollution, large acid consumption, etc., and achieve the effects of short hydrolysis time, simple operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

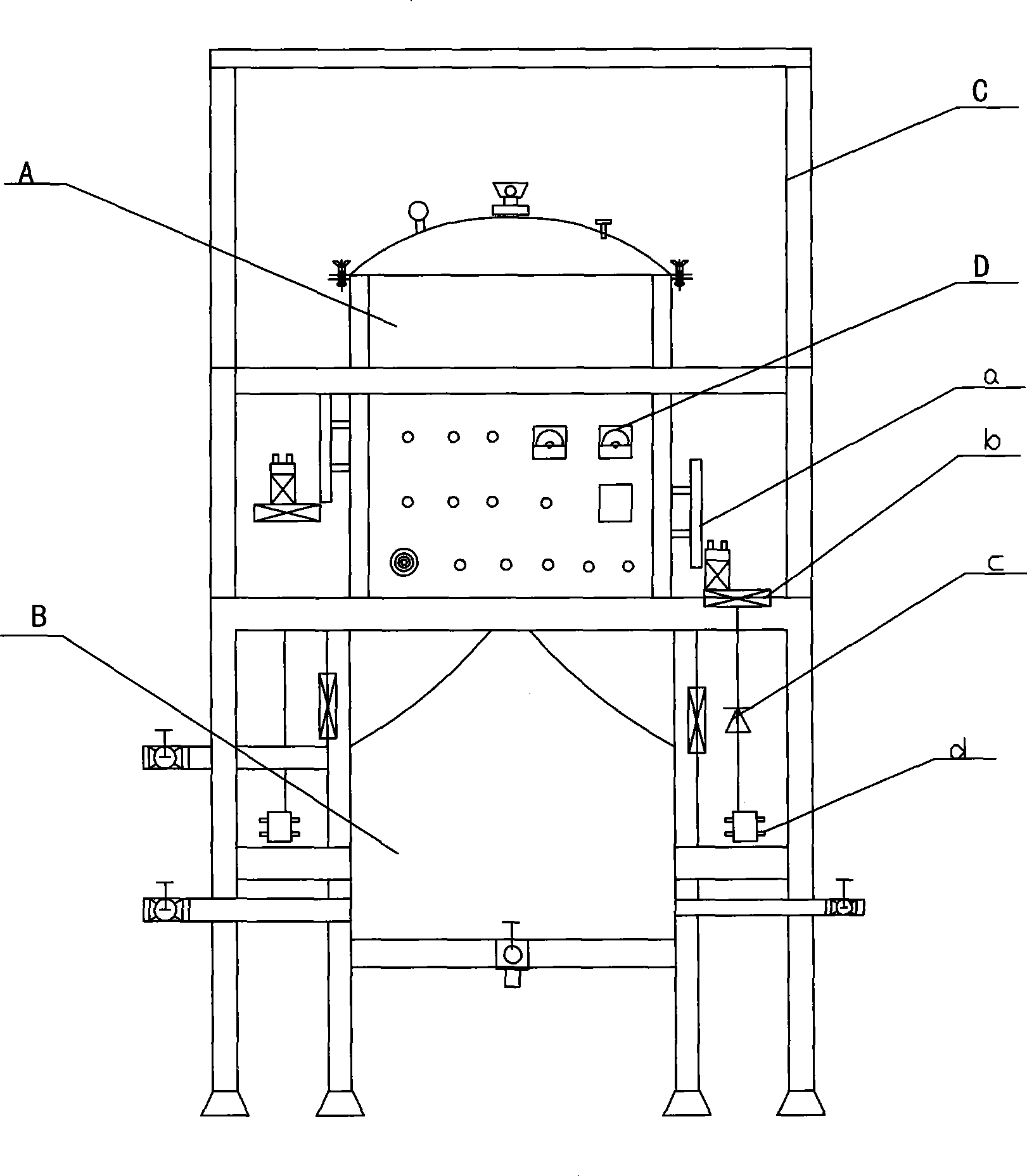

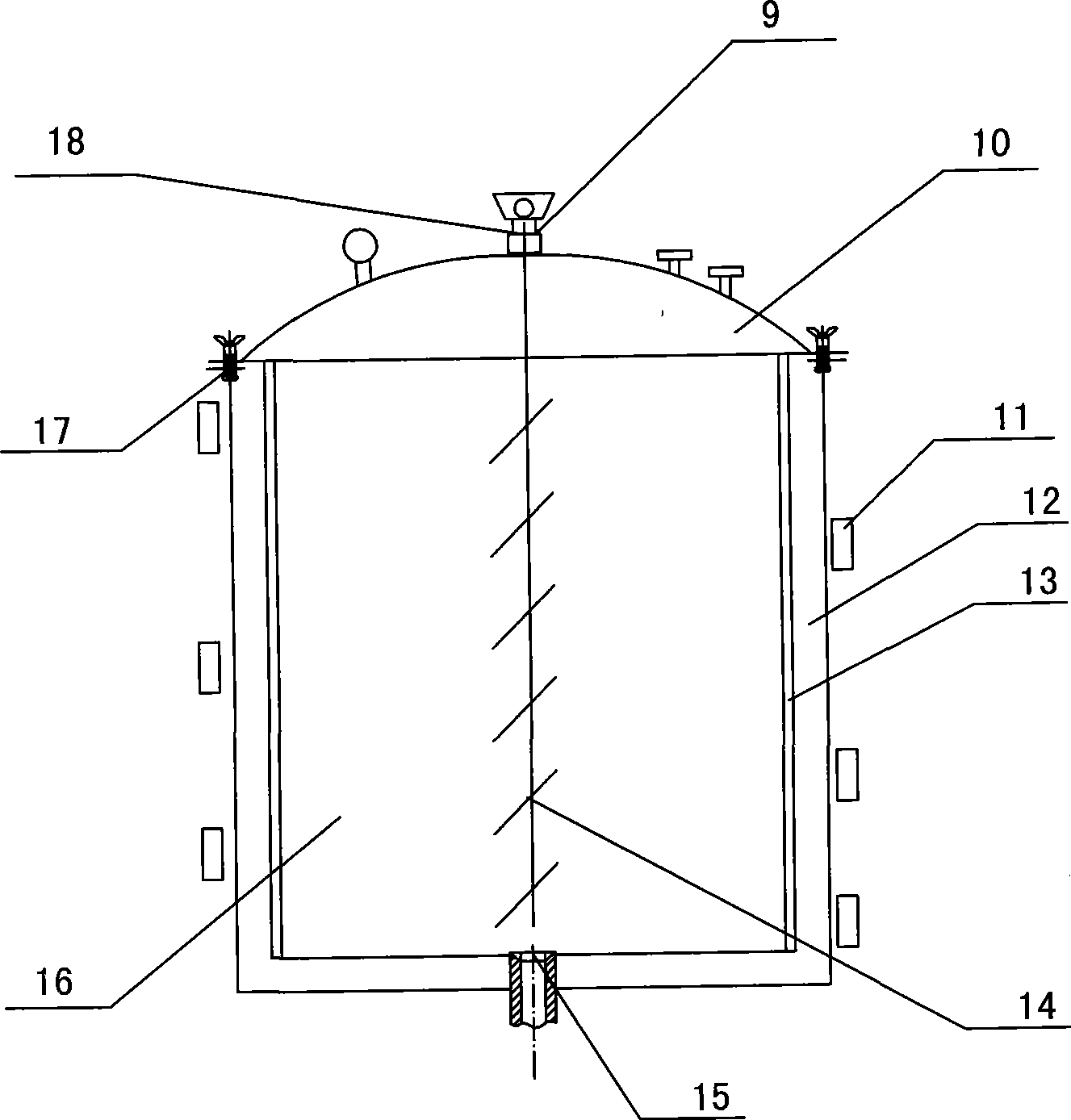

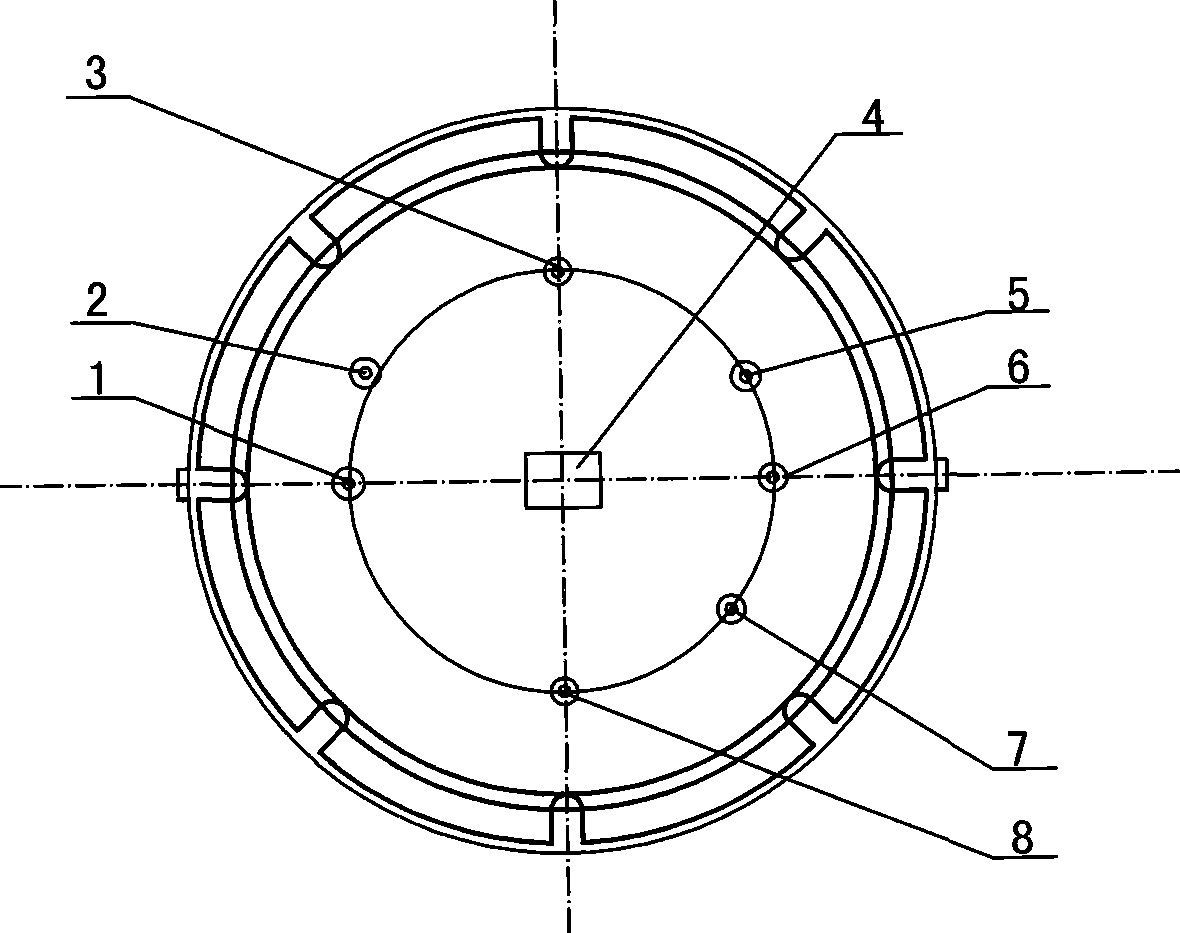

[0021] like figure 1 As shown, open the feeding port 1, put the raw materials into the hydrolysis tank A, the hydrolysis tank A is composed of a tank body 16, a tank cover 10, a microwave generator 11, and a stirrer 4, a hydrolysis tank A, a rinse tank B, a dashboard D is fixed on the frame C, the hydrolysis tank A and the flushing tank B are connected by a valve 15, and microwave generators 11 are spirally arranged around the hydrolysis tank A. The microwave generator 11 is installed on the outer wall of the hydrolysis tank A, and the microwave generator 11 is composed of a magnetron a, a cooling fan b, a rectifier c, and a transformer d. The tank cover 10 is connected to the upper part of the hydrolysis tank A by the valve blue 17, the lower part of the hydrolysis tank A is connected to the flushing tank B by the valve 15, the stirrer 4 is placed on the hydrolysis tank A, and the stirring rod 14 is placed in the tank body 16.

[0022] Close all inlet and exhaust valves, adj...

Embodiment 2

[0025] like figure 1 As shown, open the feeding port 1, put the raw materials into the hydrolysis tank A, the hydrolysis tank A is composed of a tank body 16, a tank cover 10, a microwave generator 11, and a stirrer 4, a hydrolysis tank A, a rinse tank B, a dashboard D is fixed on the frame C, the hydrolysis tank A and the flushing tank B are connected by a valve 15, and microwave generators 11 are spirally arranged around the hydrolysis tank A. The microwave generator 11 is installed on the outer wall of the hydrolysis tank A, and the microwave generator 11 is composed of a magnetron a, a cooling fan b, a rectifier c, and a transformer d. The tank cover 10 is connected to the upper part of the hydrolysis tank A by the valve blue 17, the lower part of the hydrolysis tank A is connected to the flushing tank B by the valve 15, the stirrer 4 is placed on the hydrolysis tank A, and the stirring rod 14 is placed in the tank body 16.

[0026] Close all inlet and exhaust valves, adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com