Continuous hydrolyzing device

A technology of hydrolysis device and rectification tower, which is used in hydrolysis preparation, separation/purification of carboxylic acid compounds, preparation of organic compounds, etc., can solve the problems of poor catalyst mass transfer effect, reduction of workshop utilization rate, strong corrosiveness of sulfuric acid, etc. , to achieve the effect of shortening the hydrolysis time, reducing energy consumption, and shortening the hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

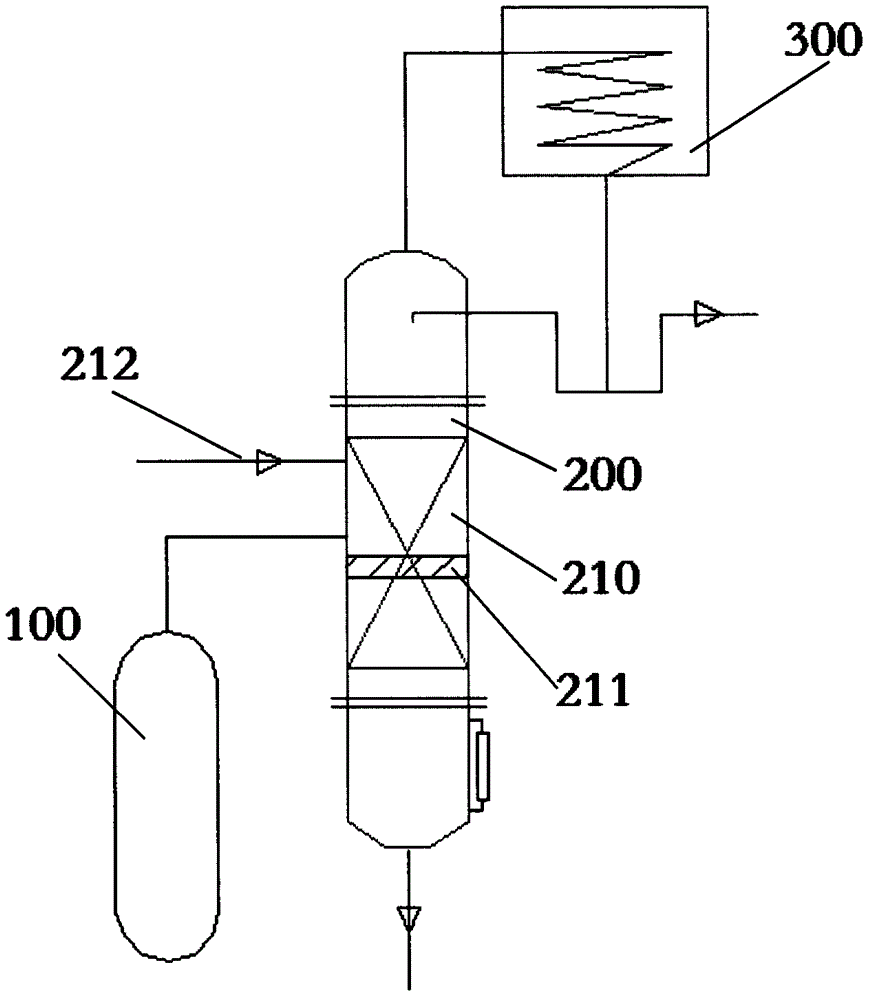

[0017] refer to figure 1 , is a structural representation of the present invention. In this embodiment, the continuous hydrolysis device includes a reboiler 100, a rectification tower 200 and a condenser 300, the rectification tower 200 is provided with a catalytic section 210, and the catalytic section 210 is provided with a solid acid catalyst 211, The catalytic section 210 on the rectification column 200 is provided with a material inlet 212 , the reboiler 100 is connected to the catalytic section 210 , and the condenser 300 is connected to the top of the rectification column 200 . The solid acid catalyst 211 is a molecular sieve catalyst.

[0018] The working principle of the present invention is: the raw material isopropyl cyclopropanate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com