Process for producing amino acid from blood of slaughtered livestock and poultry

A technology of livestock and poultry blood and amino acids, which is applied in the field of biochemistry, can solve the problems that chemical drugs and high-temperature heat treatment methods do not meet the requirements of obtaining high-quality amino acids, invest a lot of money and management costs, and are not ideal and effective methods, so as to achieve no loss of blood nutrition, The effect of low production cost and short hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

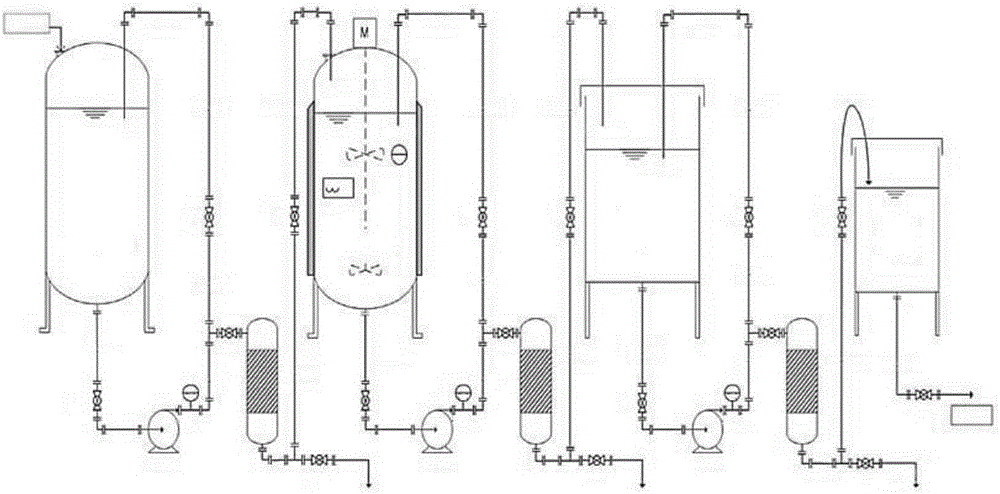

Image

Examples

Embodiment 1

[0026] 1. Concentration of blood raw materials: the blood is stored in a 200Kg storage tank under normal temperature and normal pressure. The blood will coagulate under the action of red blood cells, but it will not affect the subsequent processing. The detection will be used for the next process on the premise of no corruption and deterioration. .

[0027] 2. Blood raw material processing: Send the collected coagulated blood into a grinding tank for cell wall breaking treatment, mix the coagulated plasma with water at a ratio of 8:2, and use the OH atomic group multistage pump (OHradical ) stirring, and repeated rotation at a speed of 3600RPM for 20 minutes to 3 minutes, the hydroxide radical (OH-) of the OH atomic group is fully combined with the hydrogen ion (H-) on the cell membrane to produce water (H 2 O), thereby eliminating the hydrogen ions (H-) on the cell membrane and causing the cell membrane to rupture. Therefore, the OH radical can effectively destroy the blood ...

Embodiment 2

[0033] In the 3rd step, the subtilisin of the proteolytic enzyme is changed to Bacillus licheniformis protease, and other implementation processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com