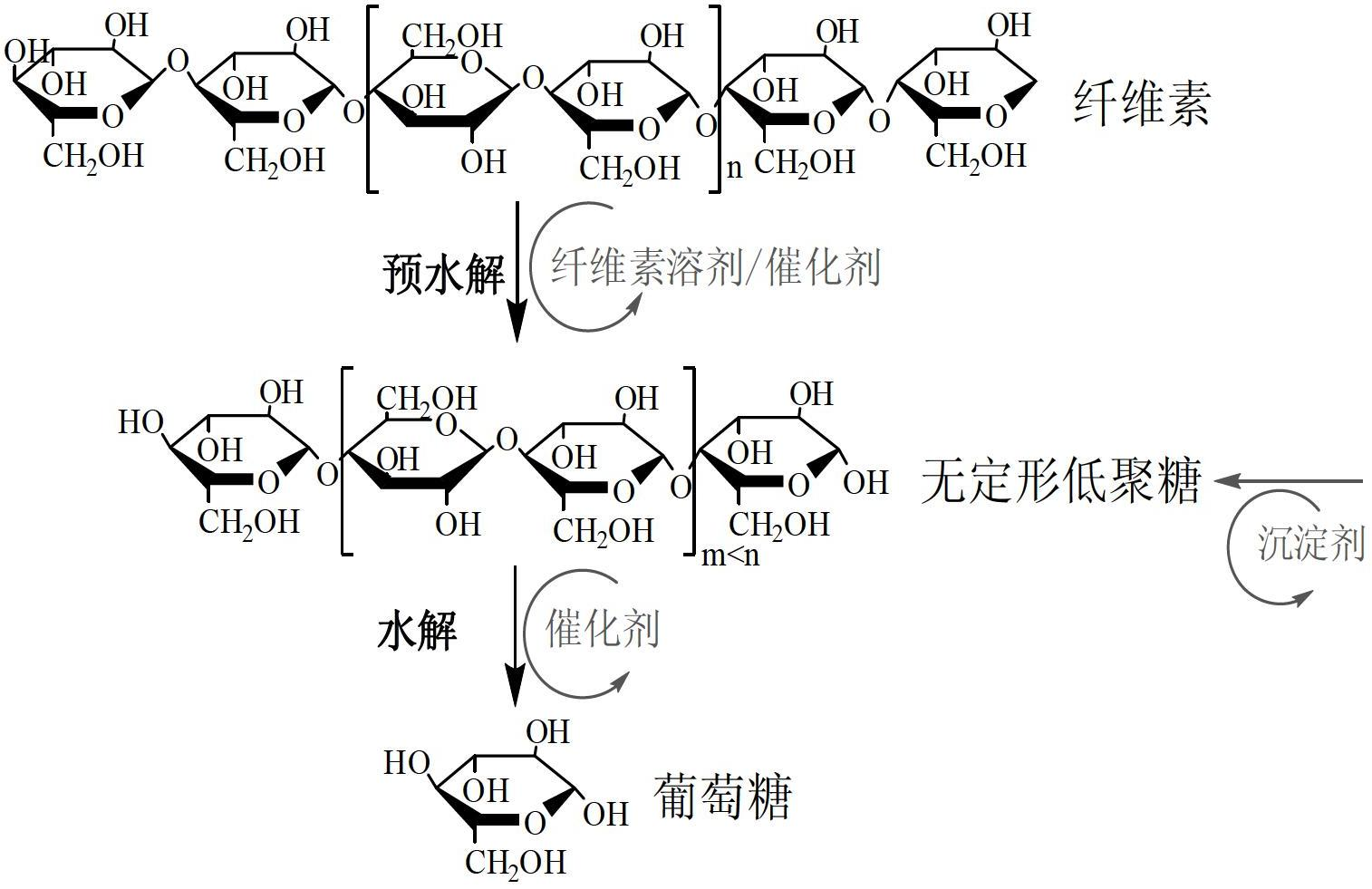

Two-step hydrolysis method for preparing reducing sugars with cellulose

A cellulose dissolving and cellulose technology, applied in the production of sugar, sugar production, glucose production, etc., can solve the problems of large amount of liquid inorganic acid, high cost of enzymatic hydrolysis, difficult separation of hydrolyzed products, etc. The effect of less amount, mild hydrolysis conditions and simple subsequent treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

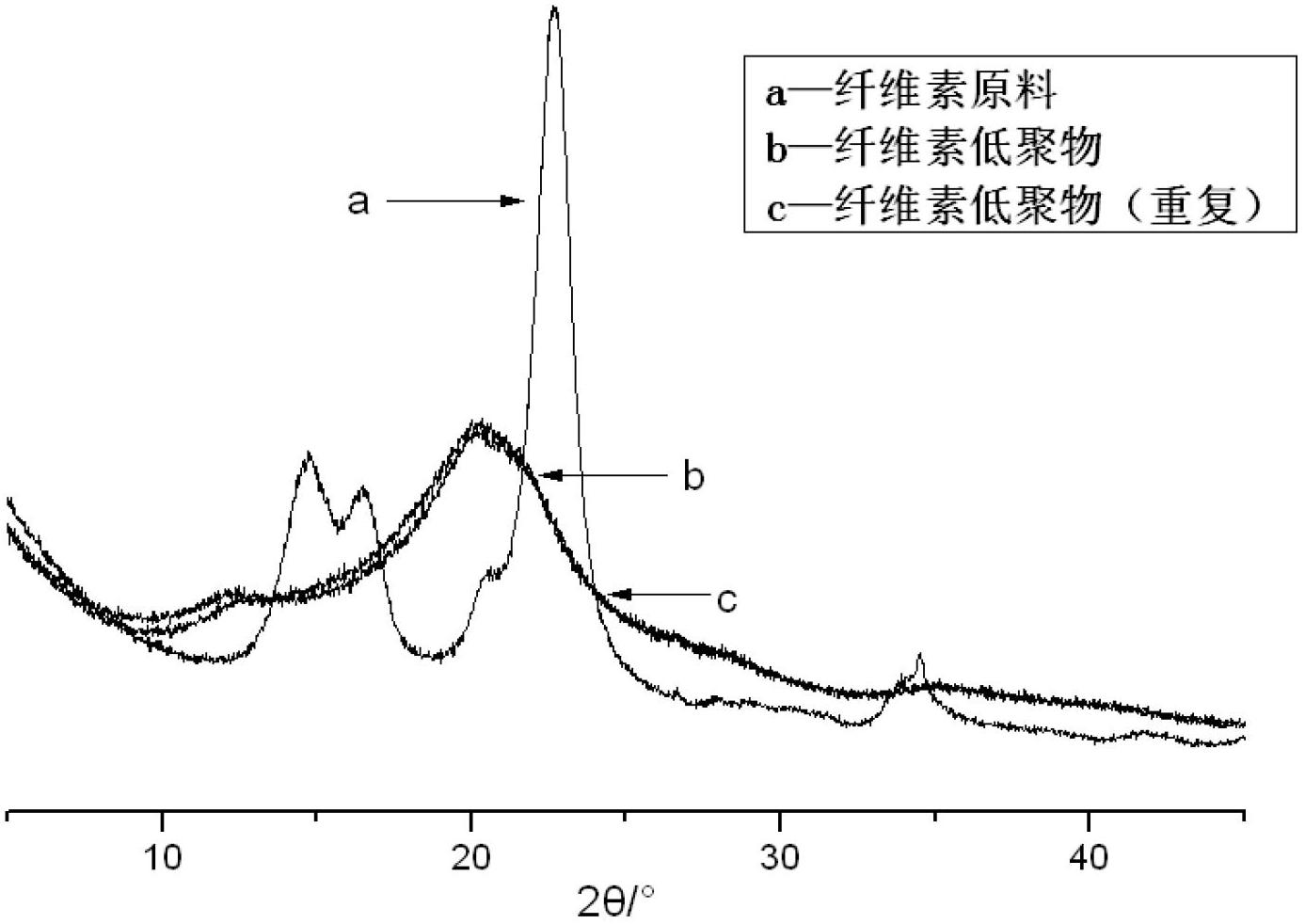

[0040] 12.5g of ionic liquid (1-ethyl-3-methylimidazole chloride salt) is heated to 90℃, stirred for 15min to melt, then 2.5g of cellulose is added, stirred for 30min to obtain a cellulose solution, and 0.5g of the first catalyst is added under stirring Amberlyst A-15, 0.75g water, perform the first hydrolysis at 90℃ for 15min to obtain the hydrolysate, add 200mL of precipitant isobutanol to the hydrolysate to precipitate cellulose oligomers, filter and wash the obtained cellulose oligomers The material was placed in 40 mL of water, 1 g of the second catalyst Amberlyst A-15 was added, and the second step of hydrolysis was carried out at 160° C. for 2 h. The yield of reducing sugar determined by DNS method reached 70.4%.

Embodiment 2

[0042] 12.5g of ionic liquid (1-ethyl-3-methylimidazole chloride salt) was heated to 90℃, stirred for 15min to melt, then 2.5g of cellulose was added, stirred for 30min to obtain a cellulose solution, and 0.5g of the first catalyst was added under stirring Amberlyst A-15, 0.75g of water, conduct the first hydrolysis at 90℃ for 25min to obtain the hydrolysate, add 200mL of precipitant isobutanol to the hydrolysate to precipitate cellulose oligomers, filter and wash the obtained cellulose oligomers The material was placed in 40 mL of water, 1 g of the second catalyst Amberlyst A-15 was added, and the second step of hydrolysis was carried out at 160° C. for 2 h. The yield of reducing sugar determined by DNS method reached 76.8%.

Embodiment 3

[0044] 12.5g of ionic liquid (1-ethyl-3-methylimidazole chloride salt) was heated to 90℃, stirred for 15min to melt, then 2.5g of cellulose was added, stirred for 30min to obtain a cellulose solution, and 0.5g of the first catalyst was added under stirring Amberlyst A-15, 0.75g of water, conduct the first hydrolysis at 90℃ for 35min to obtain the hydrolyzed liquid, add 200mL of precipitant isobutanol to the hydrolyzed liquid to precipitate cellulose oligomers, filter and wash the obtained cellulose oligomers The material was placed in 40 mL of water, 1 g of the second catalyst Amberlyst A-15 was added, and the second step of hydrolysis was carried out at 160° C. for 2 h. The yield of reducing sugar determined by DNS method reached 81.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com