Patents

Literature

60results about How to "Mild hydrolysis conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial production method of hydrolyzed wheat protein for feeding

InactiveCN101627793AConfiguration highAdvanced configurationAnimal feeding stuffAccessory food factorsHydrolysateCombined treatment

The invention discloses an industrial production method of hydrolyzed wheat protein for feeding, belonging to the technical field of feed additive production. In the method, through the method of synergy of multiple enzymes and combined treatment of multiple steps, the hydrolyzed wheat protein for feeding is prepared by taking wheat gluten meal and water with weight ratio of 1:10-1:2 and adding compound enzyme, ensuring the mass percent concentration of the compound enzyme in the solution is 0.2-1.4%, hydrolyzing the mixture for 1-13h under the conditions that the temperature is 30-70 DEG C and pH value is 5.0-10.0, then carrying out such processes as filtering, decoloring and drying, etc. Compared with the traditional methods, the method of the invention features mild hydrolysis conditions, sanitation and safety and maintains the original nutritive composition of amino acid free of loss; the hydrolysate is low in salt content, mellow in mouth feel and high in yield which is up to 98%. The tests that the hydrolyzed wheat protein is added in the feed for suckling pigs, chicks, calves, aquaculture and the like to be used show that the hydrolyzed wheat protein has the advantages and evident effects of improving daily feed intake, reducing diarrhea rate, enhancing immunity, slowing weanling stress, improving growth performance and the like.

Owner:郑州新威营养技术有限公司

Method for using compound biological enzyme in plant extraction process, and conditions thereof

InactiveCN102242100AAchieve the purpose of extractionImprove extraction efficiencyHydrolasesOrganic compound preparationWater bathsPectinase

The invention relates to a method for using compound biological enzyme in a plant extraction process, and conditions thereof. The compound biological enzyme comprises 5-60% of cellulose, 5-30% of hemicellulase, 5-50% of diastase, 5-50% of pectinase and 1-25% of protease, wherein the sum of the weight percentages of the components is 100%, and activity unit of the compound biological enzyme is 200000 U / g-1200000 U / g. The method for using the compound biological enzyme comprises: completely crushing a substrate until the substrate can passes a sieve having 80-200 meshes; adding the substrate to a water bath solution according to a ratio of material to liquid of 1:5-1:8; adjusting a pH value of the water bath solution to 4.0-5.0 through a acid (for example, acetic acid, oxalic acid, citric acid and the like); adding the compound biological enzyme to the water bath solution according to a certain ratio based on different substrates, followed by stirring completely and uniformly. A water bath temperature is controlled between 15-60 DEG C. The extraction time is controlled to 1-72 hours. The compound biological enzyme addition comprises the following conditions that: when the substrates are flowers, leaves or fruits of land plants, the compound biological enzyme addition is 0.1-0.5% of the substrate mass; when the substrates are roots and stems of the land plants, the compound biological enzyme addition is 0.3-0.8% of the substrate mass; when the substrates are marine plants, the compound biological enzyme addition is 0.8-3% of the substrate mass.

Owner:WEIHAI KANGBOER BIOLOGICAL PHARMA +1

Method for preparing collagen peptides by using fresh yak bones

InactiveCN102229971AAvoid smallNo pollution in the processPeptide preparation methodsFermentationUltrafiltrationEnzyme

The invention relates to a method for preparing collagen peptides using fresh yak bones. The final product of collagen peptides is obtained by hydrolyzing marrow-removed yak bones with enzymes twice, allowing precipitation, filtering, performing ultrafiltration and spray-drying. The preparation method adopts safe raw materials and has a simple and rapid process. The product has a low molecular weight and is easy to absorb. Besides, the cost is reduced and the low-carbon and environmentally-friendly effect is achieved.

Owner:苏州北商智业管理咨询有限公司

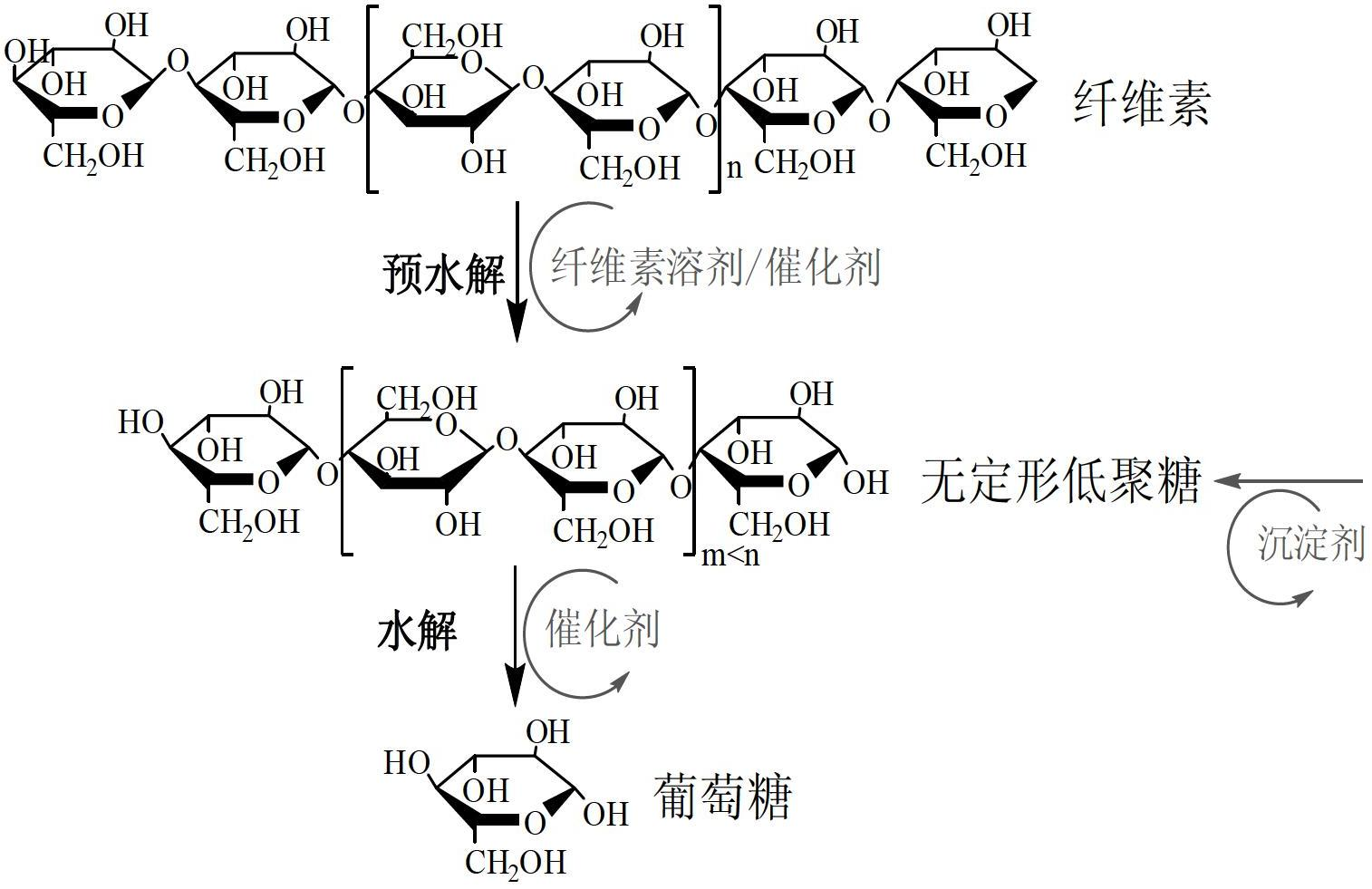

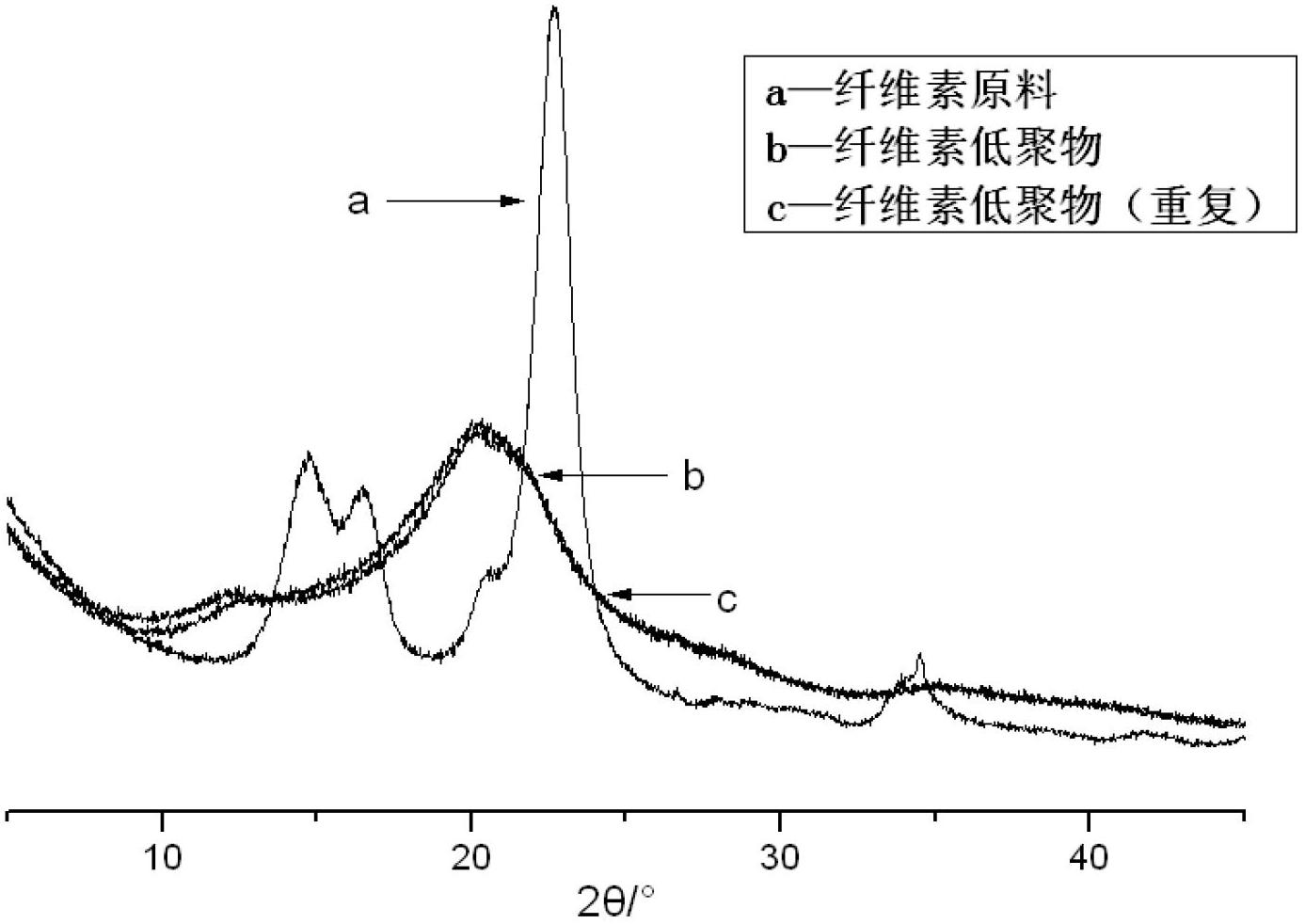

Two-step hydrolysis method for preparing reducing sugars with cellulose

ActiveCN102690897AEffective separation and reuseReduce dosageGlucose productionCelluloseIndustrial fermentation

The invention discloses a two-step hydrolysis method for preparing reducing sugars with cellulose, comprising the following steps: step (1) of dissolving the cellulose into a solvent to obtain a cellulose solution; in the cellulose solution, enabling the cellulose to contact water by the action of a first catalyst to perform a first-step hydrolysis and obtain hydrolysate; adding a precipitator into the hydrolysate, and separating after precipitating to obtain precipitate; step (2) of adding a second catalyst in the precipitate obtained in the step (1) by utilizing water as a medium to perform a second-step hydrolysis and obtain the reducing sugars, wherein productivity of the reducing sugars reaches 40-85%. The invention further discloses application of the two-step hydrolysis method for preparing reducing sugars with cellulose in fermentation and preparation for compounds such as ethanol, lactic acid and so on in the carbohydrate industry. Cellulose solvent, catalyst and precipitator utilized by the invention can effectively separated and used repeatedly; hydrolysis condition is relatively mild; dosage of acid catalysts is less; and the method is featured with simple operation, low energy consumption, fast reaction and high productivity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

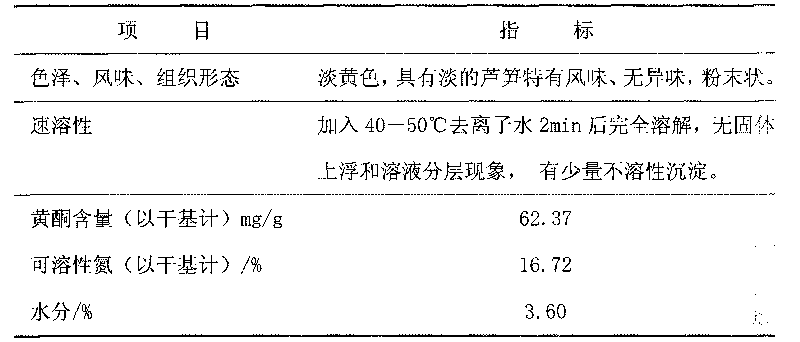

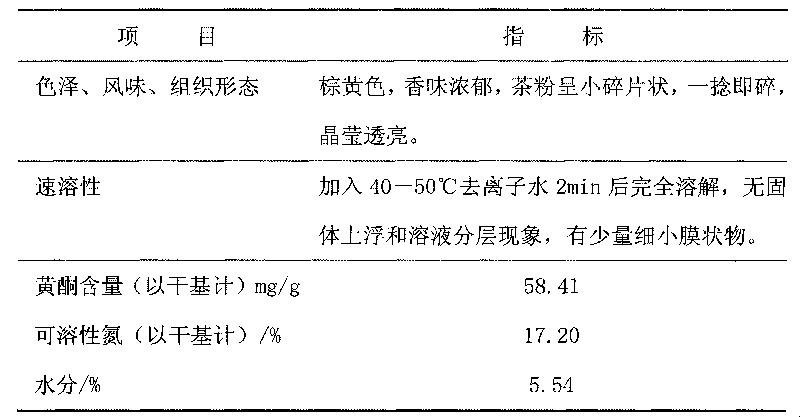

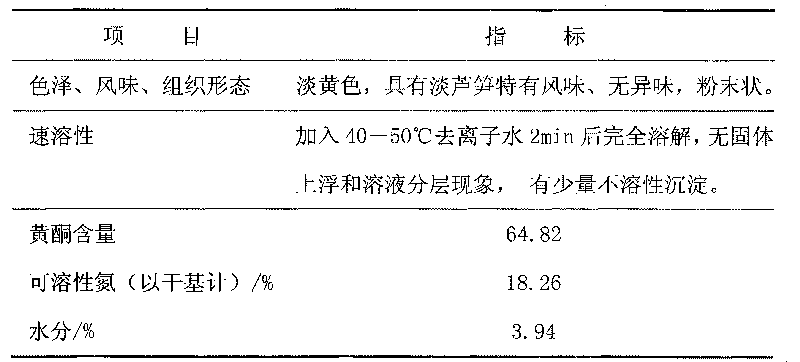

Preparation method of asparagus leaf instant tea

InactiveCN101715848AIncrease soluble nitrogen contentImprove immunityPre-extraction tea treatmentCelluloseInstant tea

The invention belongs to a preparation technology of an instant tea, relating to a preparation method of an asparagus leaf instant tea. As the prior art only picks vegetable asparagus, and loses the asparagus leaf, wherein the weight of the asparagus leaf is 70%-80% of the gross weight of plant, thereby wasting the resources; and the asparagus leaf is rotten, thereby polluting the environment. The preparation method of the asparagus leaf instant tea comprises the following four steps of: microwave inactivating enzyme of the asparagus leaf-composite formulating the leaf instant tea-hydrolyzing complex enzyme-concentrating and drying. The preparation technology has the advantages that the asparagus leaf instant tea has higher flavone content and soluble nitrogen content, and has physiological functions for enhancing human body immunity and anti-fatigue, and the like; is convenient in drinking, and can be drunken by adding water; is easy in storing and transporting; has a scientific and reasonable technology; has an energy-saving production technology, and is easy in controlling and operating; adopts an assistant extraction method with complex enzyme of cellulose and neutral protease to have mild hydrolysis condition and low ash content; and has wide raw materials source, abundant resource, low price, low cost and wide practicability.

Owner:SHANGHAI NORMAL UNIVERSITY

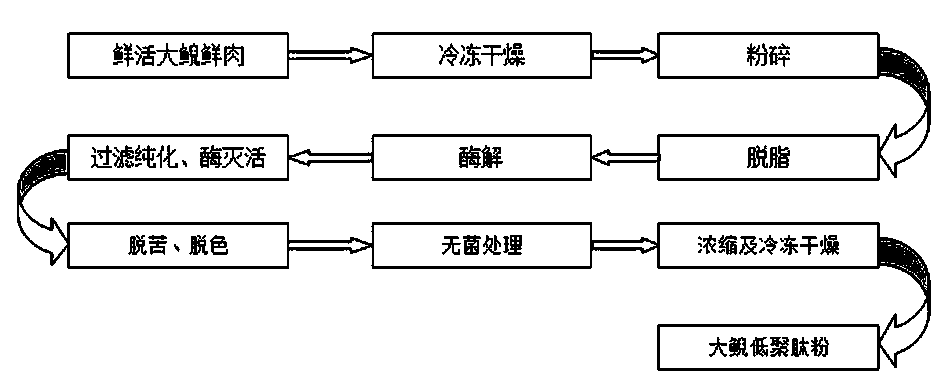

Preparation method of andrias oligopeptide

InactiveCN103361393APromote digestionPromote absorptionPeptide preparation methodsFermentationNeutral proteaseFreeze-drying

The invention discloses a preparation method of andrias oligopeptide. The preparation method takes human-bred andrias as the raw material and obtains andrias oligopeptide through enzymolyzing andrias protein by animal protease and neutral protease. The preparation method comprises steps of pre-treating, enzymolyzing, purifying, inactivating enzyme, debittering, decoloring sterilizing, condensing and freeze drying. The preparation method has the advantages that: the hydrolysis conditions are mild, specific polypeptide can be generated by positioning hydrolysis, and the hydrolysis process is easy to control. The product has the advantages of easiness in digestion and absorption, high safety, little nutrition loss during the production and environmental friendliness. The product can be applied to medicine raw material, drug, and functional food. In the same time, the preparation method has the advantages of advanced technology, safety, environmental-friendliness, vast application areas, low cost, high addition value, and suitability for industrial production.

Owner:四川龙王洞生态农业开发有限公司

Hydrolytic method of Chinese potato saponin

The invention relates to a hydrolysis method of dioscin. A solid acid catalyst is added to the reaction solution containing the dioscin according to the proportion of 0.1g to 100g / 100ml of extract and then the reaction solution is placed in water bath of 50 DEG C to 90 DEG C for reaction for 2h to 16h; after the hydrolysis, the reactant obtained is cooled to the room temperature and filtered in vacuum and the filter residue is dried at the temperature of 20 DEG C to 80 DEG C; the filter residue is extracted in organic solution for 4h to 12h continuously, the extract is separated and the organic solution thereof is recycled; finally the dioscin solid is obtained. The solid acid catalyst system adopted by the invention is a multiphase reaction; hydrogen ions are restrained on the surface of the catalyst rather than going into the body of the reaction solution, therefore, the acidification of the reaction solution is avoided and the loss of the hydrogen ions is rather small. The experimental result shows that the pH value of the solution phase after hydrolysis is 4 to 5 and the concentration of the hydrogen ions in the solution is 10,000 times lower than that of the solution which is hydrolyzed by hydrochloric acid, thus greatly reducing the pollution to the environment. The hydrolysis method has simple technology, moderate hydrolysis conditions and high hydrolysis conversion rate of the dioscin which is as high as 98 percent, thus fundamentally solving the problems of serious environmental pollution and equipment corrosion occurring in the inorganic acid catalysis hydrolysis process.

Owner:HENAN UNIVERSITY

Stewed chicken with mushroom seasoning packet suitable for non-fried miscellaneous-grain instant noodles, and production method thereof

ActiveCN102845728APromote absorptionImprove adsorption capacityFood preparationBiotechnologyMonosodium glutamate

The invention discloses a stewed chicken with mushroom seasoning packet suitable for non-fried miscellaneous-grain instant noodles. The seasoning packet comprises a sauce packet, and a powder packet. The sauce packet comprises the raw materials of: chicken paste, mushroom extract, chicken oil, palm oil, ginger, green onion, garlic, soy sauce, a yeast extract, a flavoring, xanthan gum, and turmeric powder. The powder packet comprises the raw materials of: edible salt, white granulated sugar, monosodium glutamate, I+G (nucleotide disodium), maltodextrin, yeast powder, chicken powder, food flavoring, onion powder, garlic powder, pepper powder, and ginger powder. The invention also discloses a production method thereof. The seasoning packet has the advantages that: the chicken paste, the powder, and the mushroom extract are prepared with a biological enzyme wall-breaking method, such that nutrients are abundant, and are easy to absorb by human bodies. The seasoning packet has natural fragrance and taste like those obtained by home stewing; good color, fragrance, and taste can be provided for the non-fried miscellaneous-grain instant noodles, such that mouthfeel requirements and nutrient demands of consumers can be satisfied; the production method is simple and is easy to command; the technology is mature; and the method provided by the invention is suitable for popularization.

Owner:SICHUAN JIUJIUAI FOOD

Method for producing giant salamander polypeptide powder liver protection capsules

InactiveCN103394071AMild hydrolysis conditionsThe hydrolysis process is easy to controlHydrolysed protein ingredientsDigestive systemEnzyme digestionGiant salamander

The invention discloses a method for producing giant salamander polypeptide powder liver protection capsules. The method comprises the following steps of: performing low-temperature drying, grinding, fat removal, controllable composite enzyme digestion, centrifugation, filtration, two-time membrane filtration, vacuum concentration, freeze drying and crushing on fresh giant salamander meat to obtain giant salamander polypeptide powder; encapsulating the giant salamander polypeptide powder, and packaging to obtain a finished product.

Owner:四川龙王洞生态农业开发有限公司

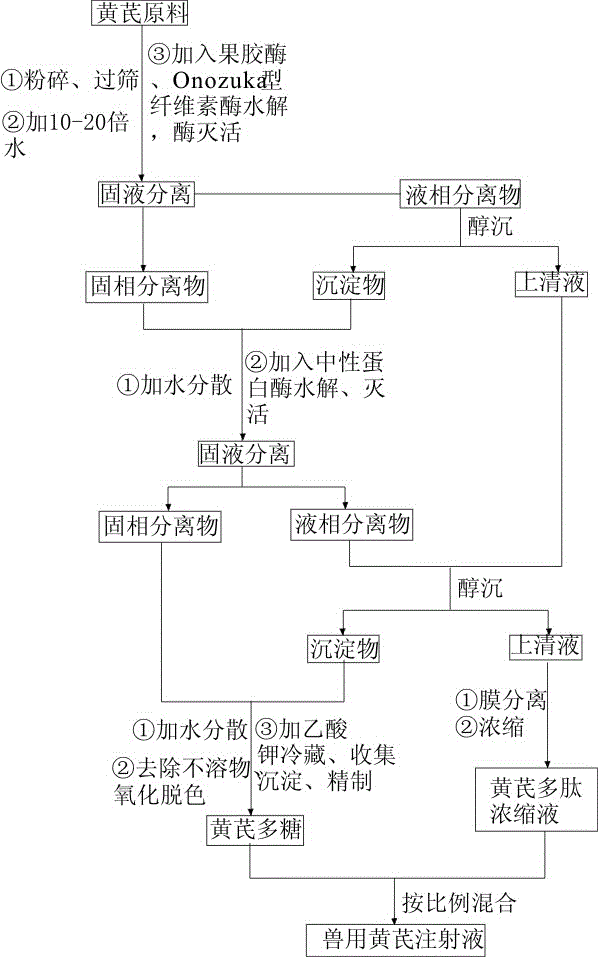

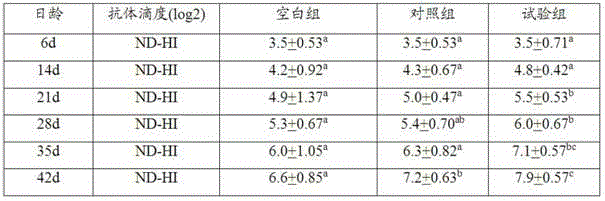

Astragalus mongholicus formulation for veterinary use and preparation method thereof

ActiveCN104367987AImprove growth performanceEasy to solveOrganic active ingredientsPeptide/protein ingredientsAstragalus polysaccharidePharmaceutical drug

The invention discloses an astragalus mongholicus formulation for veterinary use and a preparation method thereof, and belongs to the technical of extraction and application of effective components of plant traditional Chinese medicine. The medicine comprises two active ingredients including astragalus polysaccharide and astragalus polypeptide, and the form of the medicine is injection, oral liquid or powder. The preparation method includes comprehensively utilizing an enzyme hydrolysis extraction technology to effectively extract the high-activity astragalus polypeptide and the high-content high-purity astragalus polysaccharide from raw materials of astragalus mongholicus and effectively preparing the astragalus mongholicus formulation. The technical problems of comprehensive extraction and preparation are solved, further systematic and deep research on the astragalus polysaccharide and the astragalus polypeptide is facilitated, yield and purity are greatly increased, resource waste is reduced, cost is lowered, and industrialized production is facilitated.

Owner:HENAN SOAR VETERINARY PHARMA

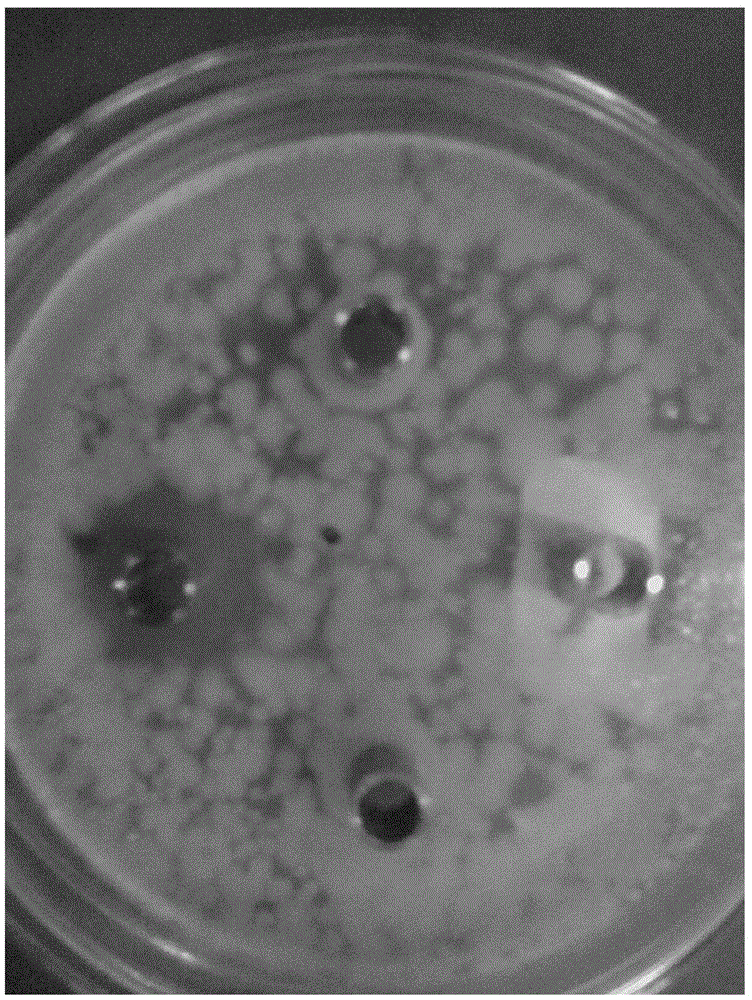

Antibacterial hairtail tetrapeptide and preparation method thereof

InactiveCN105601706AHigh antibacterial activityEasy to preparePeptide preparation methodsFermentationStaphylococcus aureusPeroxyl radical

The invention discloses an antibacterial hairtail tetrapeptide with an amino acid sequence of Gln-Ala-Glu-Gly. The invention provides a novel antioxidative peptide, i.e., hairtail tetrapeptide which is prepared through hydrolysis of alkali protease and has a hydrolysis degree of 69.52% and a hydroxyl radical scavenging rate of 76.74%. The hairtail tetrapeptide is also a novel antibacterial peptide and has strong antibacterial activity; and a hairtail tetrapeptide filtrate obtained in the invention has antibacterial activity of 85.2% and antioxidative activity of 77.8%. As the hairtail tetrapeptide is applied to Staphylococcus aureus, a minimal inhibitory concentration (MIC) is 0.20 mg / ml, and a minimal bactericidal concentration (MBC) is 0.26 mg / ml. A preparation method for the hairtail tetrapeptide in the invention is simple and only needs one-step hydrolysis; hydrolysis conditions are mild; purifying process is simple; the preparation method is applicable to any scale-up industrial production; and alkali protease is employed for hydrolysis and a hydrolysis degree is 69.52%.

Owner:ZHEJIANG OCEAN UNIV

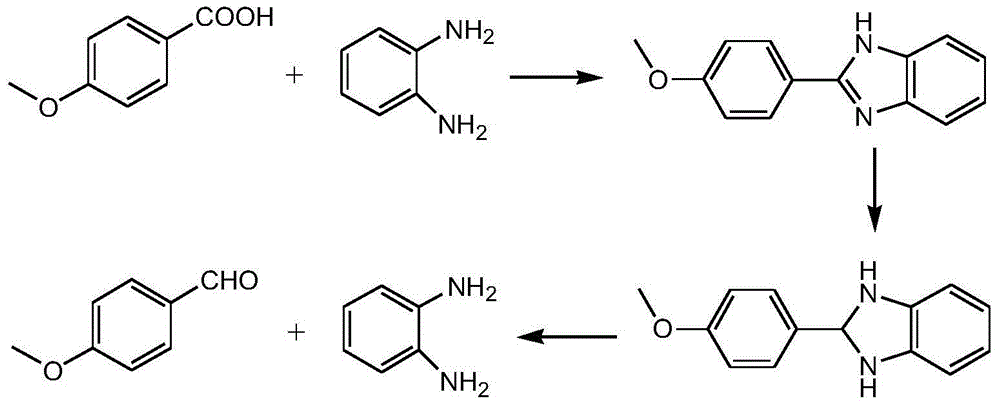

Method for preparing p-methoxybenzaldehyde by p-methoxybenzoic acid

ActiveCN103980105AHigh yieldAchieve restorationOrganic compound preparationCarbonyl compound preparation by hydrolysisHydrogen pressureReaction temperature

The invention relates to a method for preparing p-methoxybenzaldehyde by p-methoxybenzoic acid, which comprises the following steps: adding p-methoxybenzoic acid, o-phenylenediamine and a solvent in a condensation reaction kettle, wherein a catalyst is not used in the step, performing backflow water distribution when no water is generated; cooling, filtering to obtain 2-(4-methoxyphenyl)benzimidazole; adding a catalyst, absolute methanol and 2-(4-methoxyphenyl)benzimidazole in a hydrogenation reaction vessel, setting reaction temperature and hydrogen pressure, performing a hydrogenation reaction when hydrogen is unabsorbed, cooling to room temperature; recovering methanol from a filtrate, adding a sulfuric acid aqueous solution, performing backflow for reaction, then cooling to the temperature of 60-65 DEG C, separating the liquid to obtain an oil layer and a water layer, washing the oil layer to neutrality, and rectifying to obtain the final product. The preparation method has the advantages of mild reaction condition, low cost, less three wastes and easy realization of industrial production.

Owner:SUQIAN COSMOS CHEM

Preparation method of chitosan microspheres

ActiveCN106279727ADoes not reduce molecular weightMild hydrolysis conditionsPharmaceutical non-active ingredientsSolventChemistry

The invention provides a preparation method of chitosan microspheres. The preparation method comprises steps as follows: calcium removal with insect carapace diluted acid, deproteinization through compound enzymes, dissolution and purification of a mixed solvent, deacetylation of weak base through ultraviolet light and emulsification crosslinking, and the chitosan microspheres are prepared with the method. Chitosan prepared with the method has high purity, high degree of deacetylation and large molecular weight, the size of the chitosan microspheres prepared from chitosan ranges from 210 mu m to 400 mu m, the deviation is lower than 15%, and the application requirement of the chitosan microspheres in interventional therapy is met.

Owner:上海丽珠制药有限公司

Production method of water soluble flavone-chitosan derivative

InactiveCN102174123AGood moisturizing effectUniform molecular weightOrganic active ingredientsCosmetic preparationsEnvironmental resistanceMaterial resources

The invention discloses a production method of a water soluble flavone-chitosan derivative, relating to a preparation method of a flavonoid uvioresistant active substance. The production method takes chitosan and a flavone compound as raw materials, and the product is prepared by the processes of preparing a small molecular chitosan solution, synthesizing a water soluble flavone-chitosan derivative, concentrating and the like. The invention has the advantages of simple method, simplicity of operation, simple equipment, mild reaction conditions, energy conservation, full utilization of material resources in the production process, no discharge of three wastes, benefit to environmental protection, low production cost and convenience of popularization and application; and the product is characterized by being freely soluble in water, having good moistening effect and the like. The product prepared by the invention can be extensively used in skin care cosmetics and medicaments for treating skin diseases.

Owner:CHONGQING UNIV

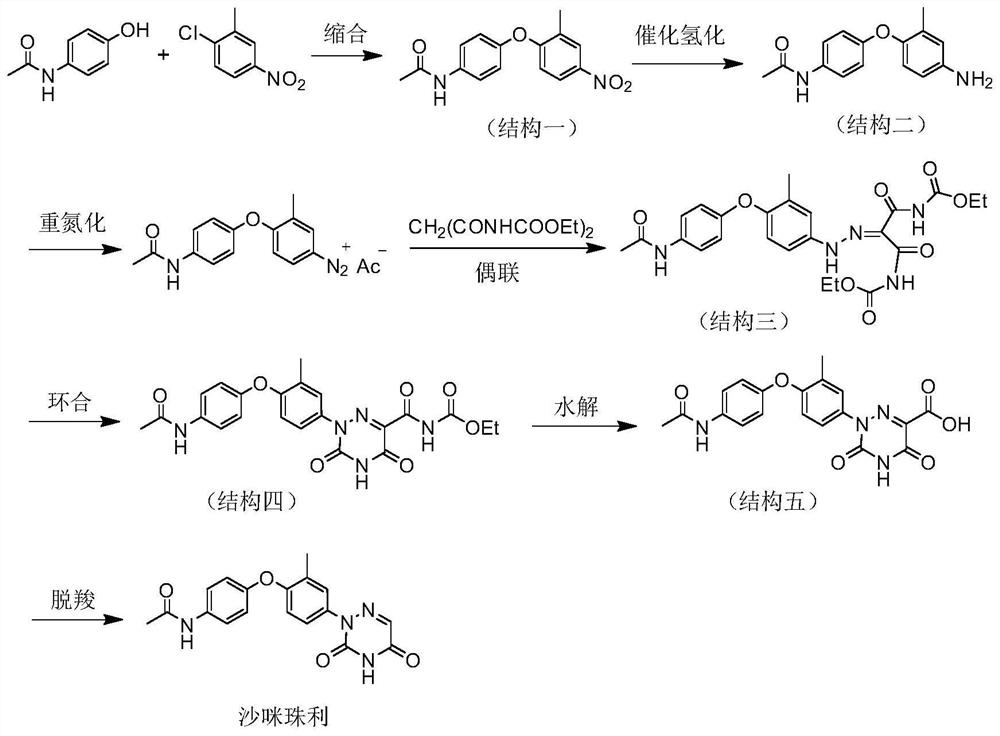

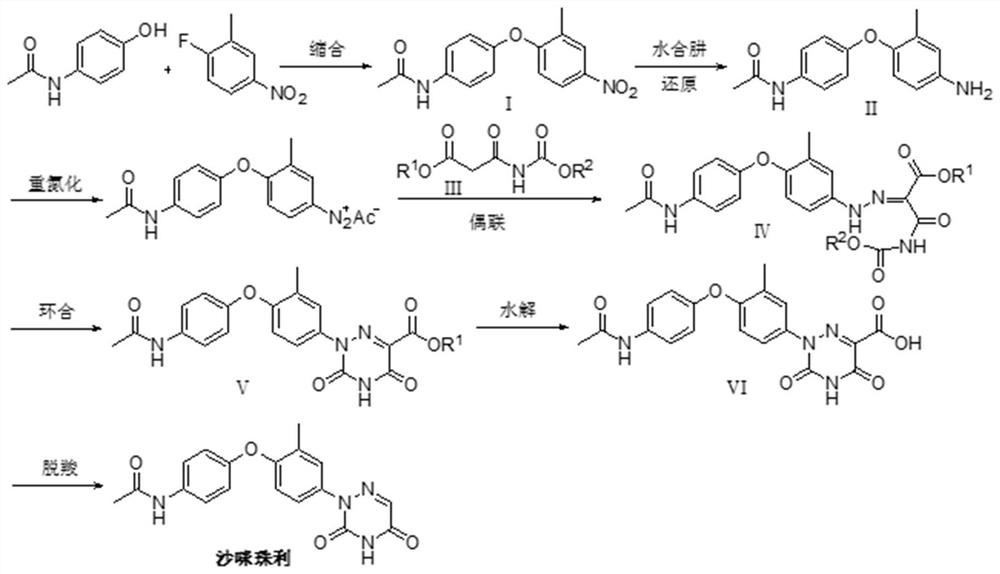

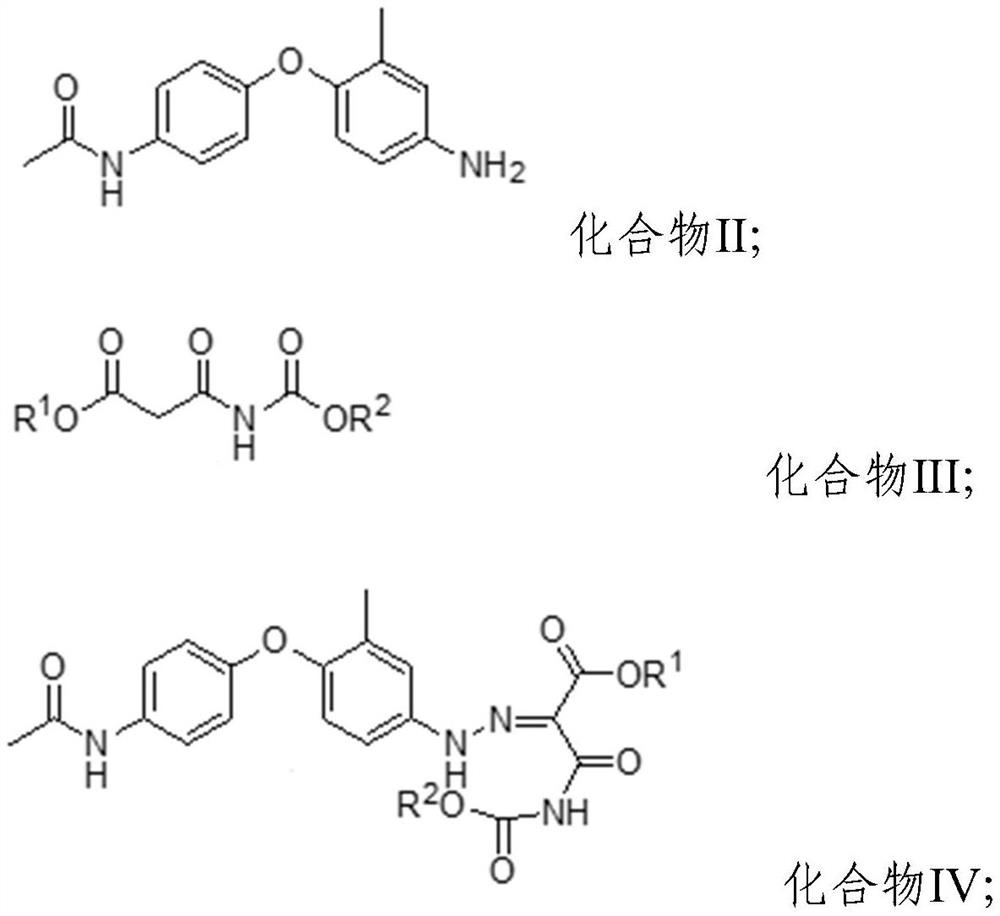

Preparation method of Ethanamizuril bulk drug

The invention provides a preparation method of a Ethanamizuril bulk drug, which comprises the following steps: reacting acetaminophen and 2-fluoro-5-nitrotoluene as initial raw materials to obtain a compound II, and carrying out diazotization coupling reaction to obtain a compound IV, wherein the conjugate adopted in the diazotization coupling reaction is a compound III. According to the preparation method of the Ethanamizuril bulk drug, malonic acid monoester monoamide formate is used as a conjugate, acetaminophen and 2-fluoro-5-nitrotoluene are used as initial raw materials, construction ofa triazine ring can be realized more efficiently and mildly, and the obtained target product samipril is higher in yield and purity.

Owner:HUBEI ZHONGMU ANDA PHARMACEUTICAL CO LTD +1

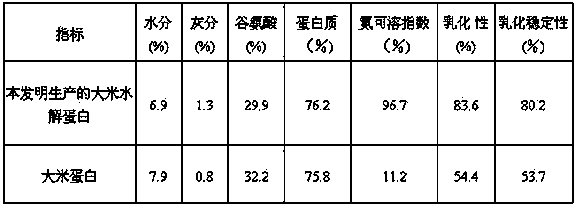

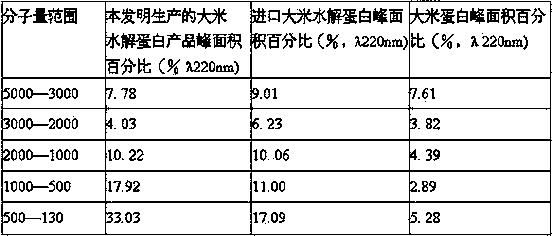

Industrial production method of rice protein hydrolysate for feed

The invention discloses an industrial production method of rice protein hydrolysate for feed, and belongs to the technical field of feed additive production. The industrial production method of the rice protein hydrolysate for the feed comprises the steps that (1) the method of synergism of various enzymes and multi-step joint processing is adopted, the solid / liquid weight ratio between rice protein powder and water is 1:2-10, and alkaline proteinase is added to carry out dissolution; (2) a complex enzyme preparation which is formed by the alkaline proteinase, neutral proteinase, papain and flavourzyme in a compound mode is added to carry out hydrolysis, and the working procedures such as enzyme deactivation, filtration, decolorization and spray drying are carried out to obtain a rice protein hydrolysate product for the feed. Compared with the traditional method, the hydrolysis conditions are moderate, hygiene and safety are achieved, the situation that original amino-acid composition nutrients are not damaged is ensured, the hydrolysate is low in salinity and mellow in taste, and the yield is high and can reach 98%. According to application tests of adding the rice protein hydrolysate to feed such as feed of suckling pigs, feed of chicks, feed of calves and feed of aquaculture, the rice protein hydrolysate for the feed has the advantages of increasing the daily food-intake amount, reducing the diarrhea rate, improving immunity, reducing weaning stress, and improving growth performance.

Owner:江苏康科食品工程技术有限公司

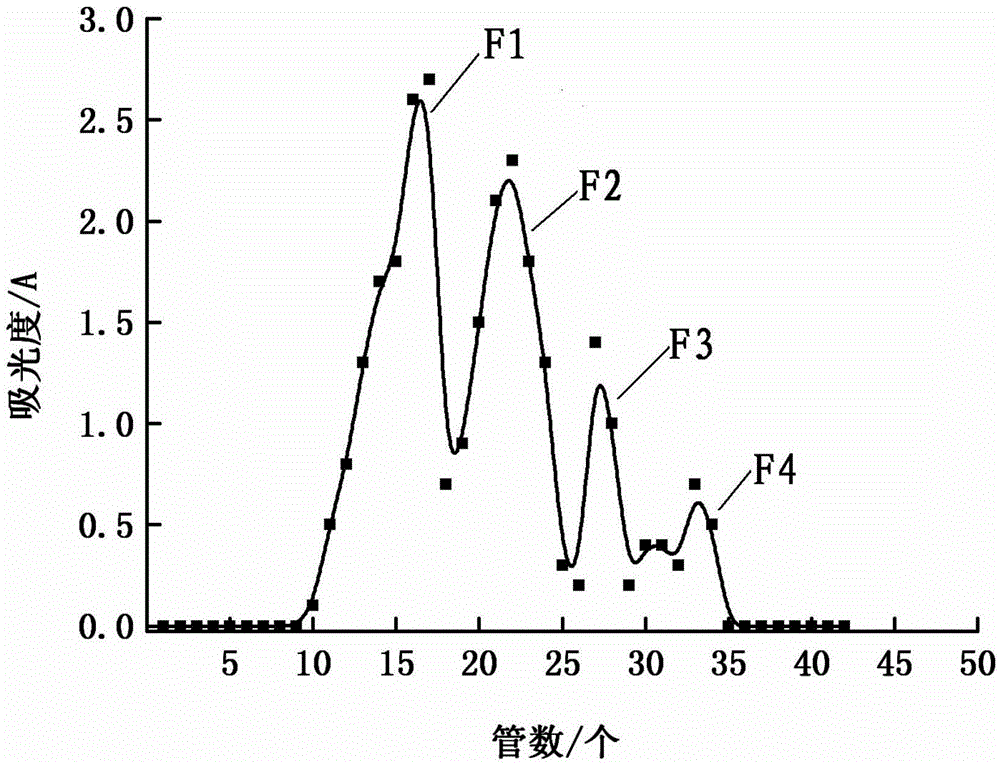

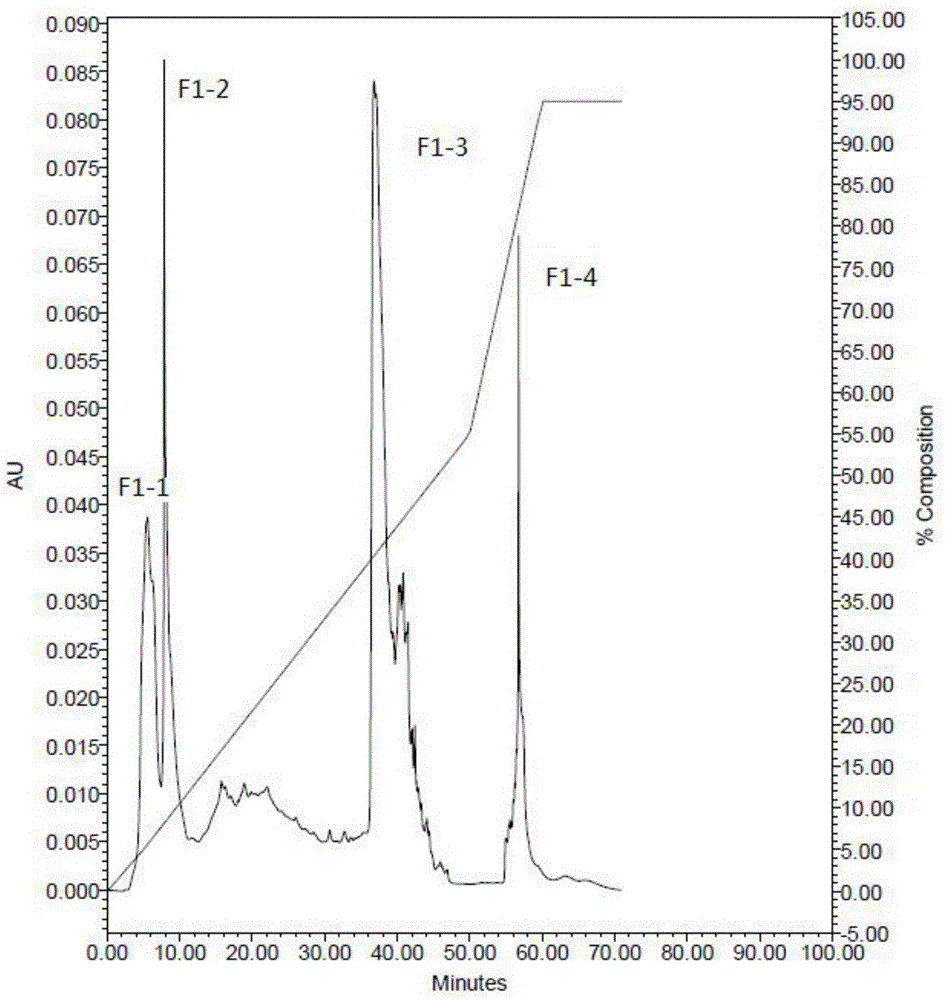

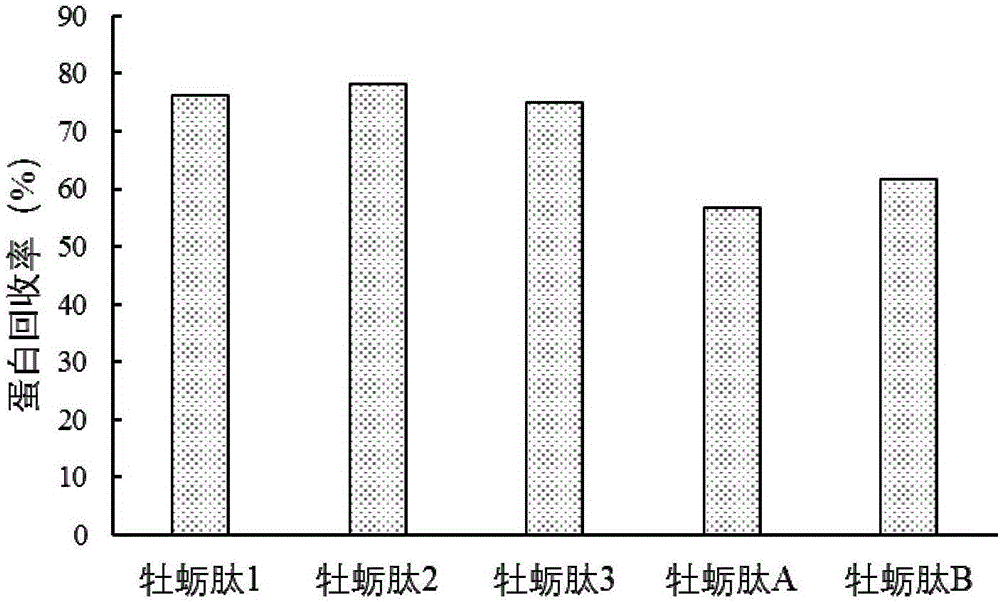

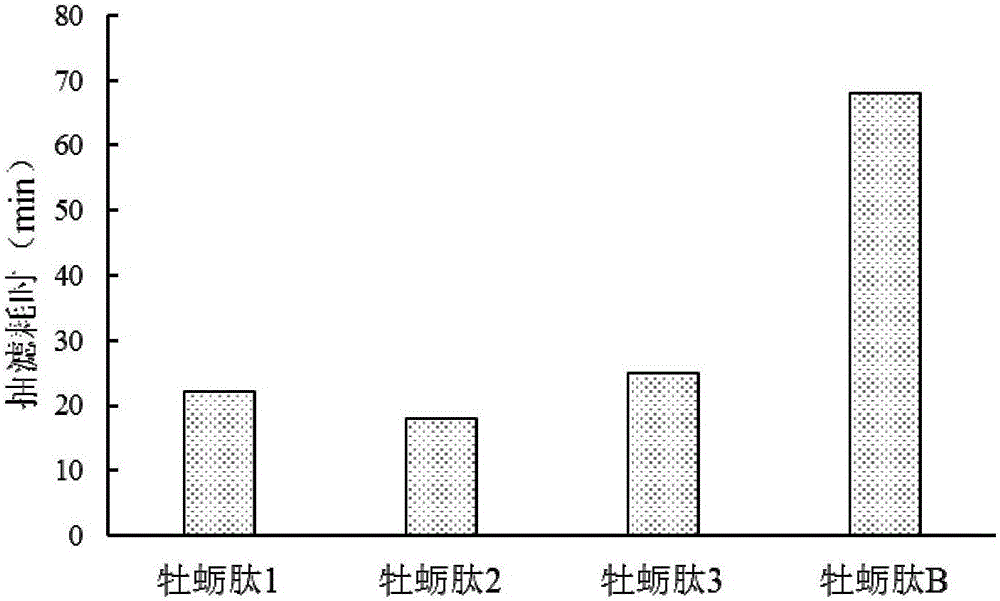

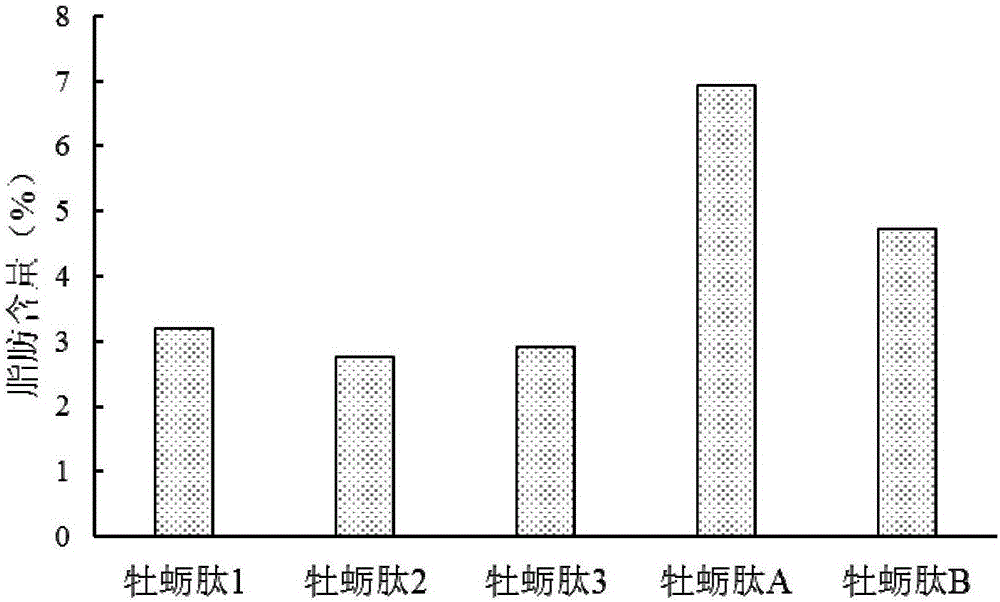

Method for quickly separating oyster peptide from oyster enzymolysis liquid

ActiveCN106243187AMild hydrolysis conditionsSafe and controllable processPeptide preparation methodsPeptideChemistry

The invention discloses a method for quickly separating oyster peptide from oyster enzymolysis liquid. The method comprises the following steps: adding an emulsifier and lipase into enzyme-deactivated oyster enzymolysis liquid, uniformly mixing, and performing hydrolysis at the temperature of 35 to 50 DEG C for 4 to 8 h to obtain a secondary enzymolysis product of oyster; adding yeast cell wall polysaccharides and active carbon into the secondary enzymolysis product, oscillating during heat preservation at the temperature of 50 to 60 DEG C for 0.5 to 1.5 h, performing vacuum suction filtration through a filter membrane of 0.5 [mu]m, and collecting filtrate to obtain the oyster peptide. According to the method, the lipase is used for hydrolyzing fat in an enzymatic hydrolysis system to break the emulsification balance in the enzymatic hydrolysis system and drive a water phase to be separated from an oil phase. The hydrolysis conditions of the method are mild, and the process is safe and controllable; large-scale industrial production can be realized.

Owner:广东健明生物科技有限公司

A kind of method of producing giant salamander polypeptide powder

InactiveCN103493969BPromote digestionPromote absorptionHydrolysed protein ingredientsDigestive systemBiotechnologyAnimal science

The invention discloses a method for producing giant salamander polypeptide powder, which comprises the following steps of low-temperature drying, crushing, fat removing, controlled enzymatic hydrolysis with a compound enzyme, centrifugation, coarse filtration, two times of membrane filtration, vacuum concentration, freeze drying, and pulverization of fresh giant salamander meat to obtain the giant salamander polypeptide powder.

Owner:四川龙王洞生态农业开发有限公司

Preparation method of natural marine compound polypeptide moisturizing agent

ActiveCN103948517AImprove utilizationGood water solubilityCosmetic preparationsToilet preparationsChemical resourceMicrobiology

The invention discloses a preparation method of a natural marine compound polypeptide moisturizing agent, which can be used as a functional additive for daily chemicals. An enzyme immobilization method is employed; a marine animal and plant protein powder and water in a weight ratio of 1:5-1:50 are added with a compound enzyme prepared through an immobilized enzyme technology, wherein the mass concentration of compound enzyme in the solution is 0.1-5%, and a reaction is carried out at the temperature of 30-80 DEG C, under pH value of 5-10 for a hydrolysis time of 1-13 h; and then the immobilized enzyme is separated out, and the reaction products are filtered, decolored and desalinized to obtain the marine compound polypeptide moisturizing agent. Compared with a traditional method, the method has the advantages of multitime recycling of the immobilized compound enzyme, mild hydrolysis conditions, high hydrolysis efficiency and no generation of industrial wastes, and is in line with the new trend of requirements of naturalness, environment-friendliness, safety and non-chemical resource on functional additives for daily chemicals.

Owner:SOUTH CHINA UNIV OF TECH +1

Chitosan preparation method

ActiveCN106243245ADoes not reduce molecular weightMild hydrolysis conditionsCentrifugationUltraviolet lights

The invention provides a chitosan preparation method, which comprises: (1) crushing the shell of the insects, placing in dilute acid, carrying out dipping cooking, filtering, taking the filter cake, and carrying out water washing-drying on the filter cake to obtain a decalcified product A; (2) placing the product A, a compound enzyme and water into a reaction container, hydrolyzing for 2-3 h under a weak alkali condition, filtering, taking the filter cake, and carrying out water washing-drying on the filter cake to obtain a protein removing product B; (3) placing the product B in a mixed solvent, adding a neutral salt, carrying out stirring dissolving for 1-3 h, filtering, carrying out pressure reducing drying on the filtrate to remove the solvent, and carrying out water washing-drying to obtain chitin; and (4) placing the chitin and a NaOH aqueous solution under ultraviolet light, irradiating for 2-3 h while carrying out an ultrasonic treatment, carrying out centrifugation, carrying out water washing on the precipitate to achieve a neutral state, and drying to obtain the chitosan. According to the present invention, the preparation method has advantages of simple preparation process, regular equipment, low production of acid and alkali waste water, and meeting of the green environmental protection production requirement, and the obtained chitosan has advantages of high purity, high molecular weight and high deacetylation degree.

Owner:贵州康源生物科技有限公司

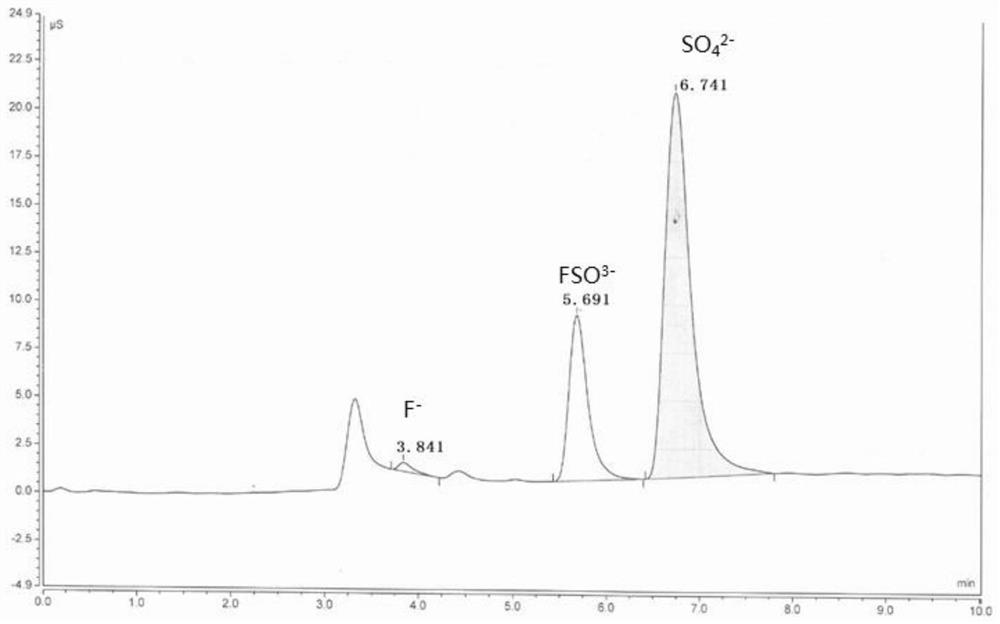

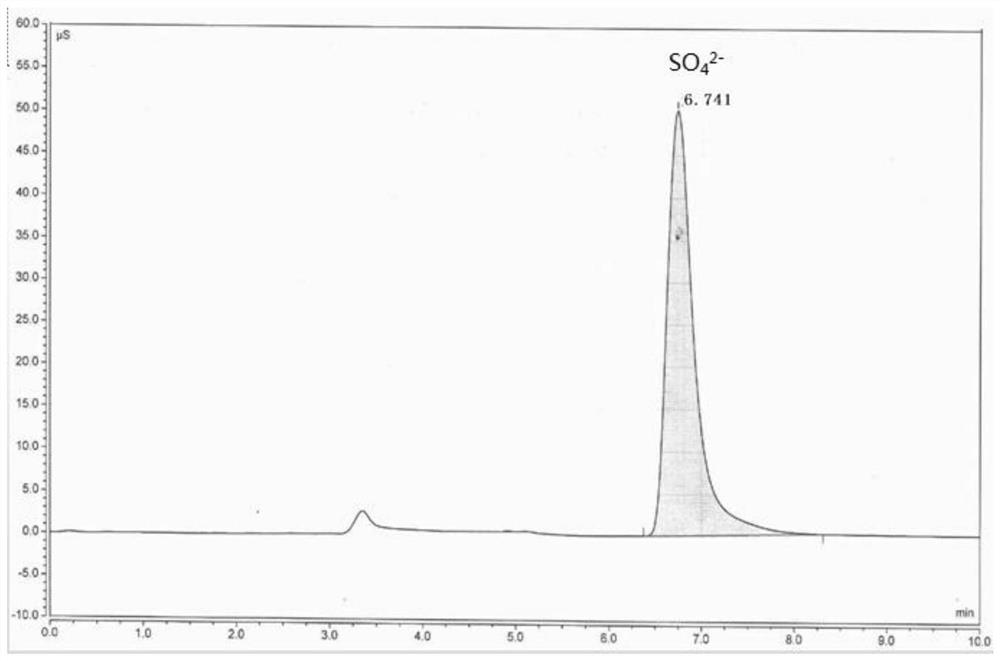

Method for recycling fluorine-containing sulfuric acid

PendingCN112645287AMild hydrolysis conditionsMild conditionsHydrogen fluorideSulfur-trioxide/sulfuric-acidHydrogen SulfateFluorosulfuric acid

The invention relates to a method for recycling fluorine-containing sulfuric acid. The method comprises the steps of under normal pressure, adding a certain amount of deionized water into a reaction kettle filled with fluorine-containing sulfuric acid, with the addition amount of the deionized water being 90 to 120% of the theoretical water amount required for hydrolyzing fluorosulfonic acid in fluorine-containing sulfuric acid; introducing inert gas which does not react with sulfuric acid, hydrofluoric acid and water, heating, collecting tail gas, and absorbing with deionized water to obtain hydrofluoric acid; and fluorine-free sulfuric acid being left in the reaction kettle. After treatment, fluorine-free sulfuric acid is finally left in the reaction kettle, and the concentration of the sulfuric acid is 80 to 98%; the content of hydrofluoric acid is below 10ppm; after the tail gas is absorbed by the deionized water, hydrofluoric acid with the concentration of 30 to 48% is obtained, and the content of sulfuric acid is 20 ppm or below. Therefore, after the fluorine-containing sulfuric acid is treated by adopting the method disclosed by the invention, high-concentration and high-purity sulfuric acid and hydrofluoric acid which are directly commercialized or produced and applied can be obtained.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

Method for preparing organic-inorganic hybrid film

The invention discloses a method for preparing an organic-inorganic hybrid film. The method comprises the following steps: 1, diluting alkoxysilane in anhydrous ethanol, gradually dropwise adding appropriate amounts of deionized water and a weak acid or a weak base to adjust the pH value for hydrolysis, heating the obtained solution to 40-70 DEG C while sufficiently stirring, performing intense stirring at a constant temperature for 8-16 h to fully hydrolyze the solution, and cooling the hydrolyzed solution to room temperature; 2, adding a small amount of an organic polymer to the obtained solsolution to change the viscosity of the sol, and adding an appropriate amount of a plasticizer to adjust the plasticity of the sol; 3, coating a multilayer support with the sol in a dip-coating manner for 10 s; and 4, carrying out constant-temperature and constant-humidity drying on the coated multilayer support at a temperature of 20-50 DEG C and a humidity of 30-90% for 6-72 h, slowly raising the temperature to 200-500 DEG C, and calcining the multilayer support under the protection of an inert gas for 2-6 h to prepare the organic-inorganic hybrid film.

Owner:广州汉至蓝能源与环境技术有限公司

Glucosamine produced by enzymic method and preparation method of glucosamine

The invention relates to glucosamine produced by using an enzymic method and a preparation method of the glucosamine. According to the glucosamine produced by using the enzymic method, the glucosamine, namely amino monosaccharide is obtained by taking chitosan as a substrate, adding water and glacial acetic acid to form colloid, then adding chitosan endonuclease and chitosan exonuclease for enzymolysis, removing protein after enzymolysis, and drying the enzymatic hydrolysate. The preparation method comprises the following steps: A, adding water to the chitosan to meter the volume; B, adding glacial acetic acid to uniformly mix; C, heating; D, adding the chitosan endonuclease and the chitosan exonuclease; E, carrying out heat preservation for enzymolysis; F, removing the enzyme to obtain the enzymatic hydrolysate; G, drying the enzymatic hydrolysate. The glucosamine and the preparation method disclosed by the invention have the advantages that the glucosamine is the amino monosaccharide, which is beneficial to the human body to absorb without side effects; the bio-enzyme is used as a catalyst, so that the production cost is greatly reduced; the production procedures are simple, and the product quality is stable; the production period is short, and the energy consumption is low; the enzyme hydrolysate does not contain hazardous substances, thus the glucosamine product is green and environment-friendly and free of environmental pollution.

Owner:HUAZHONG AGRI UNIV

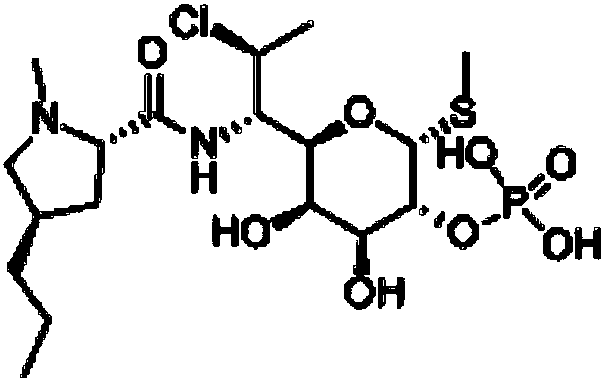

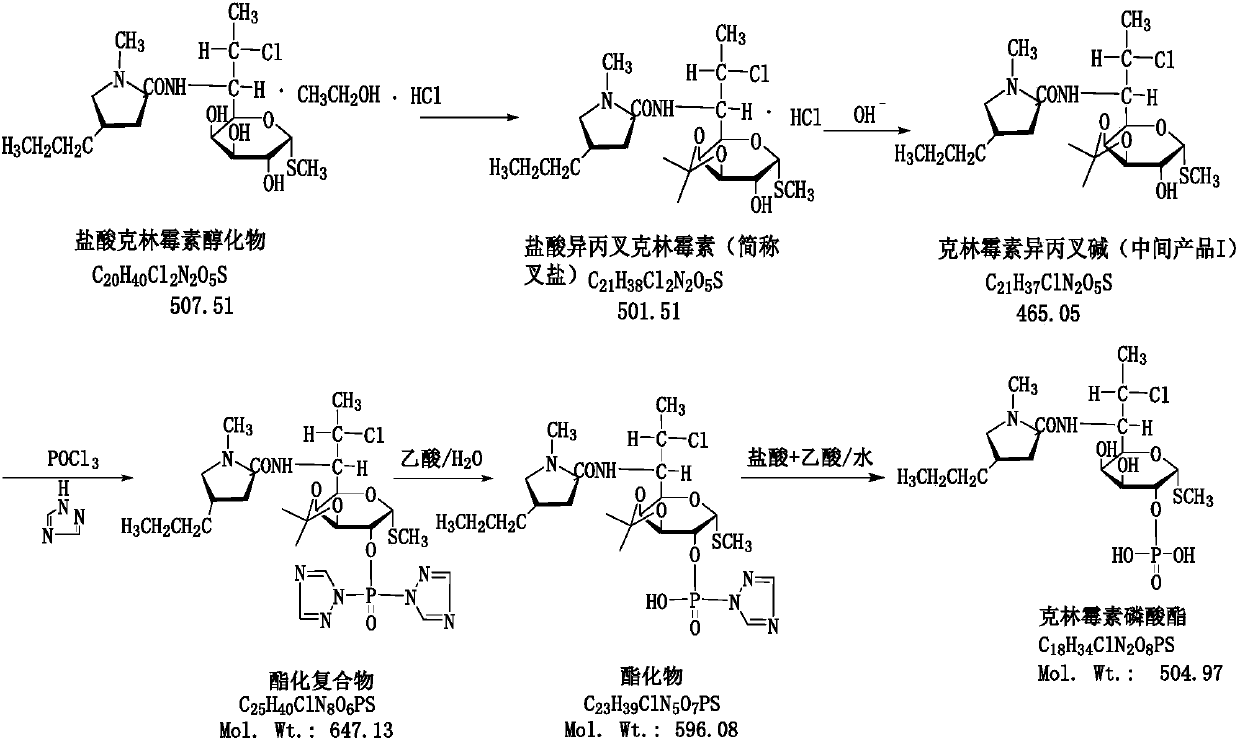

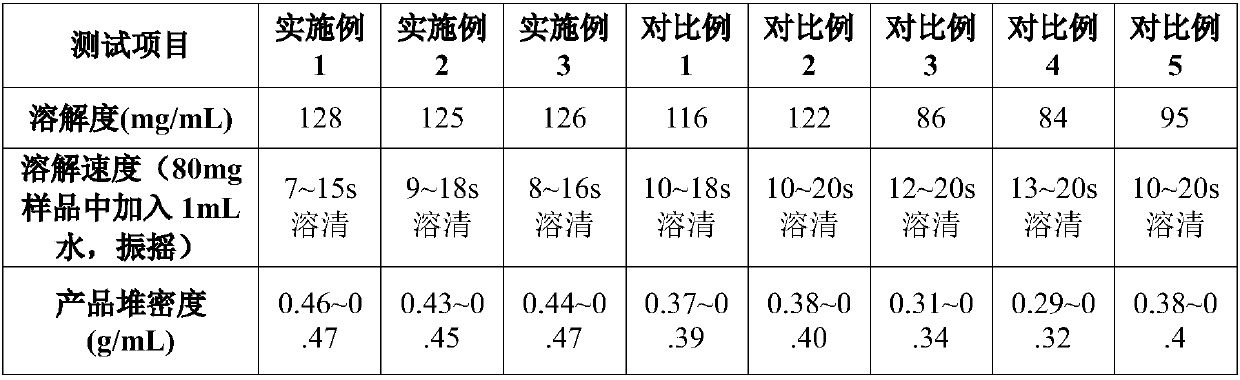

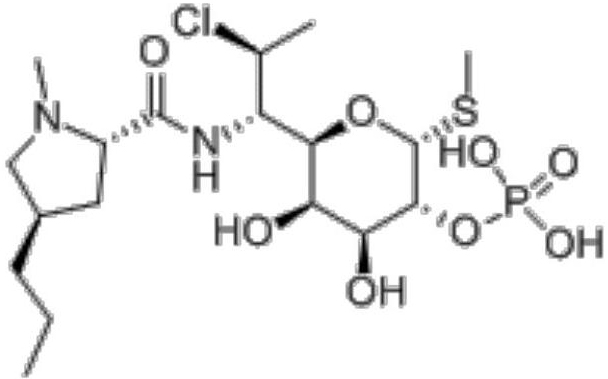

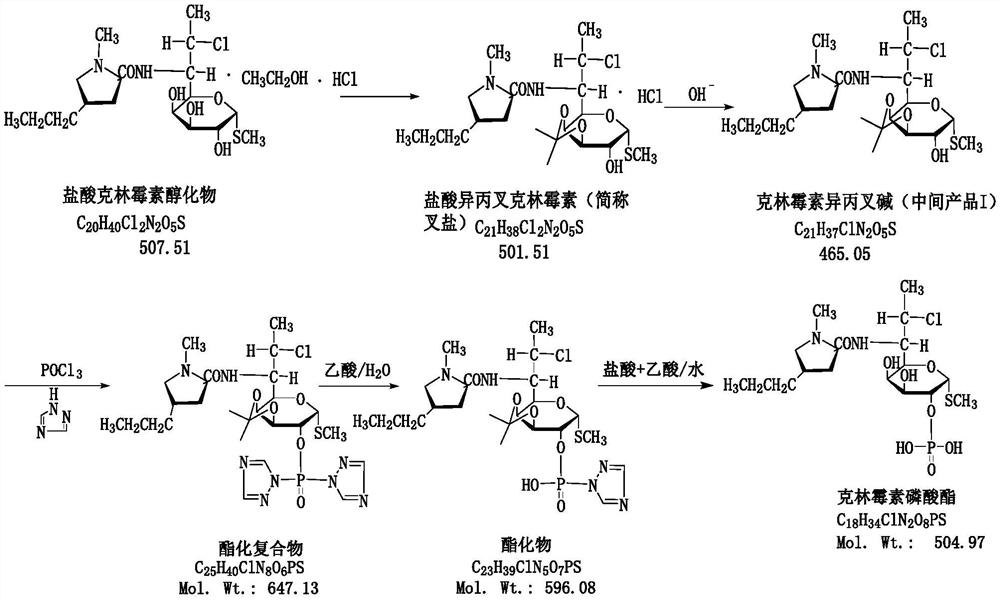

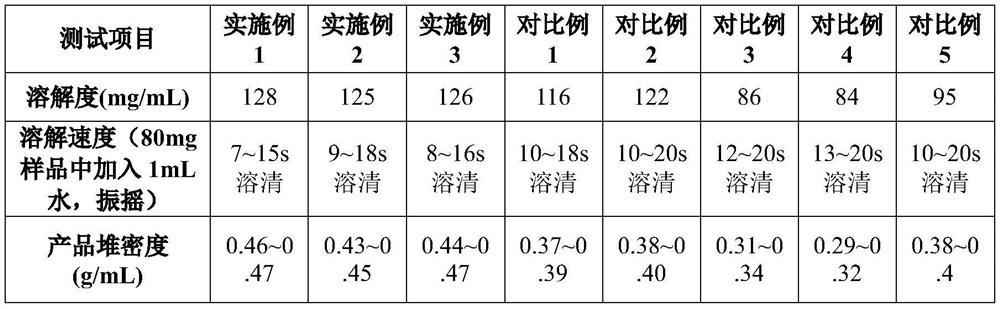

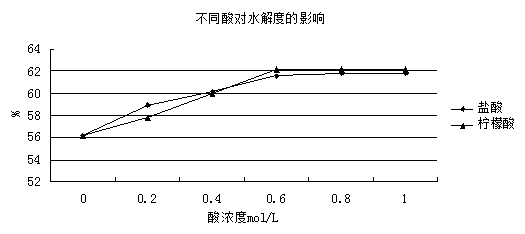

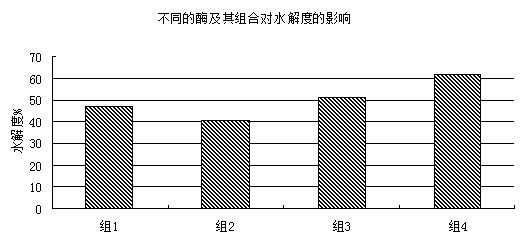

Preparation method of clindamycin phosphate

ActiveCN107652332AHigh yieldHigh puritySugar derivativesSugar derivatives preparationChemical synthesisPhosphoric Acid Esters

The invention belongs to the technical field of chemical synthesis and relates to a preparation method of clindamycin phosphate. The preparation method includes preparing clindamycin isopropylidene alkali from clindamycin hydrochloride monohydrate, subjecting the clindamycin isopropylidene alkali to phosphate esterification with phosphorus oxychloride as a phosphate esterification agent and 1,2,4-triazole as an acid-binding agent to obtain isopropylidene clindamycin phosphate, and subjecting the isopropylidene clindamycin phosphate to deprotection by hydrolysis of mixed acid to obtain the clindamycin phosphate. The preparation method has the advantages that by preparing the clindamycin phosphate through one-step hydrolysis of organic acid, the preparation method is energy saving and environment friendly; the preparation method is high in yield and low in cost and can obtain the high-purity finished product directly without subsequent refining, so that the molar yield of the clindamycinphosphate can reach 96.15%; the clindamycin phosphate is good in crystal form (bulk density and liquidity), so that aseptic packaging is benefited.

Owner:福安药业集团重庆博圣制药有限公司

Method for preparing collagen protein powder from fish scales

InactiveCN103211080BPromote hydrolysisReduce dosageProtein composition from fishHydrolysisCollagen VI

The invention discloses a method for preparing collagen protein powder from fish scales. The method comprises the following steps of: (1) deordorization, decalcification and washing treatment on the fish scales; (2) cryogenic grinding treatment on the fish scales; (3) steam explosion treatment on the fish scales; (4) enzyme hydrolysis of the fish scales; and (5) preparation of the collagen protein powder from the fish scales. The production method provided by the invention is simple, less in dosage of protease, low in production cost, short in processing cycle, mild in condition, high in utilization rate of equipment and easy to realize industrialized production, and can reach an average extraction rate of above 70%. The collagen protein content in the prepared collagen protein powder reaches above 95%, the in vitro digestibility of the powder reaches above 95%, and the problem of utilization of fish scales in fish processing is well solved, so that the additional value of leftovers in the processing of aquatic products increases, and the comprehensive utilization rate of freshwater fish is improved.

Owner:宜昌湘宜水产品有限公司

A kind of preparation method of clindamycin phosphate

ActiveCN107652332BHigh yieldHigh puritySugar derivativesSugar derivatives preparationChemical synthesisPhosphoric Acid Esters

The invention belongs to the technical field of chemical synthesis and relates to a preparation method of clindamycin phosphate. The method of the present invention uses clindamycin hydrochloride alcoholate as a raw material to prepare clindamycin isopropylidene, and then uses phosphorus oxychloride as a phosphating agent and 1,2,4-triazole as an acid-binding agent, A phosphoesterification reaction occurs to obtain isopropylidene clindamycin phosphate, which is finally deprotected by mixed acid hydrolysis to obtain clindamycin phosphate. The method of the present invention prepares clindamycin phosphate by a one-step method of organic acid hydrolysis. The product is refined so that the molar yield of clindamycin phosphate can reach 96.15%, and the crystal form of the product is good (bulk density, fluidity), which is very conducive to aseptic packaging.

Owner:福安药业集团重庆博圣制药有限公司

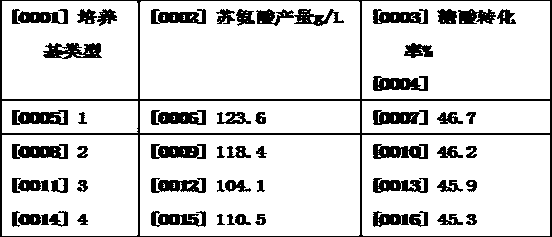

Threonine fermentation medium prepared from microbial protein

ActiveCN110846351AImprove solubilityImprove hydrophilicityMicroorganism based processesFermentationFerrous sulfate heptahydrateAmmonium sulfate

The invention belongs to the biotechnology field, and discloses a threonine fermentation medium prepared from microbial protein. The threonine fermentation medium comprises sucrose, glucose, a microbial protein and soybean protein combined hydrolysate, ammonium sulfate, potassium dihydrogen phosphate, dipotassium hydrogen phosphate, magnesium sulfate heptahydrate, ferrous sulfate heptahydrate, manganese sulfate monohydrate, VB1 and VH. The fermentation medium is prepared from the microbial protein and soybean protein combined hydrolysate, so that the fermentation yield of threonine and the sugar-acid conversion rate can be increased, and the cost is low.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

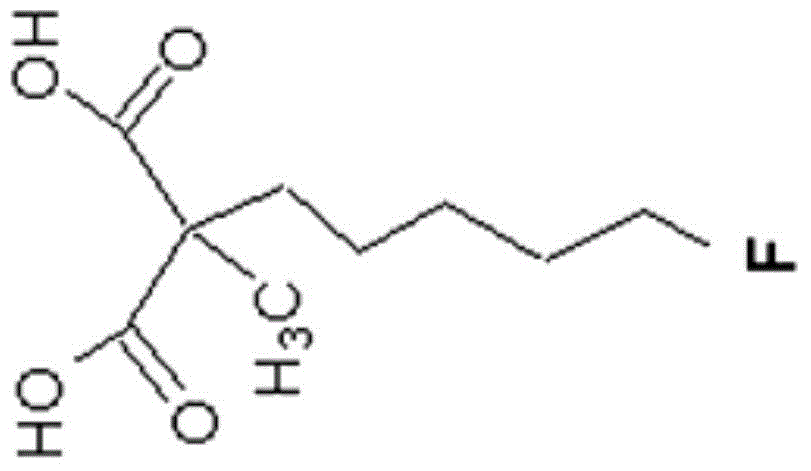

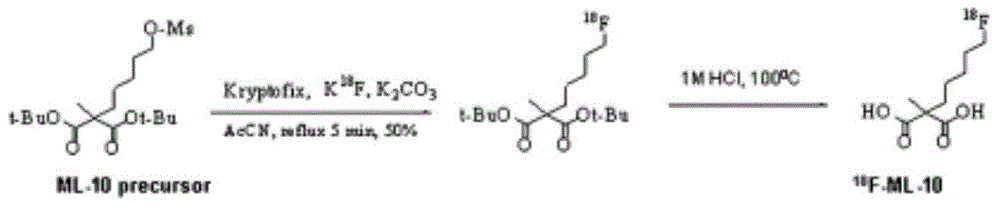

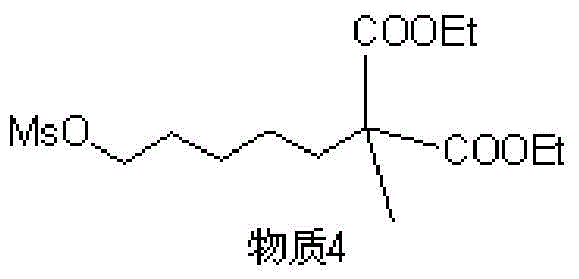

Precursors of novel PET (polyethylene terephthalate) precursor-fluoride standard ML-10 and preparation method thereof

InactiveCN103601658AHighly corrosiveMild hydrolysis conditionsOxygen-containing compound preparationOrganic compound preparationTosylBromine

The invention specifically relates to precursors of novel PET (polyethylene terephthalate) precursor-fluoride standard ML-10 and a preparation method thereof, namely 5-methylsulfonyl pentyl-2-diethyl methylmalonate, 5-toluenesulfonyl pentyl-2-diethyl methylmalonate and preparation methods of the 5-methylsulfonyl pentyl-2-diethyl methylmalonate and the 5-toluenesulfonyl pentyl-2-diethyl methylmalonate. The precursors, namely 5-methylsulfonyl pentyl-2-diethyl methylmalonate (substance 4) and 5-toluenesulfonyl pentyl-2-diethyl methylmalonate (substance 5) are synthesized by the following reaction of four steps totally under mild reaction conditions by taking 5-bromo-1-pentanol PPTS (pyridinium paratoluenesulfonate) as a reaction initiator: performing 1) the reaction of substituting a hydroxyl by a dihydropyran ring, 2) the reaction of substituting bromine by a methyl diethyl malonate group, 3) the hydrolysis reaction of the dihydropyran ring, and 4) the reaction of substituting the hydroxyl by a methllyl sulfonate group and p-toluenesulfonyl. The substance 4 and the substance 5 synthesized by the preparation method do not have related reports in the existing literature, and moreover, the stability of the substance 5 is very high.

Owner:JIANGSU HUAYI TECH

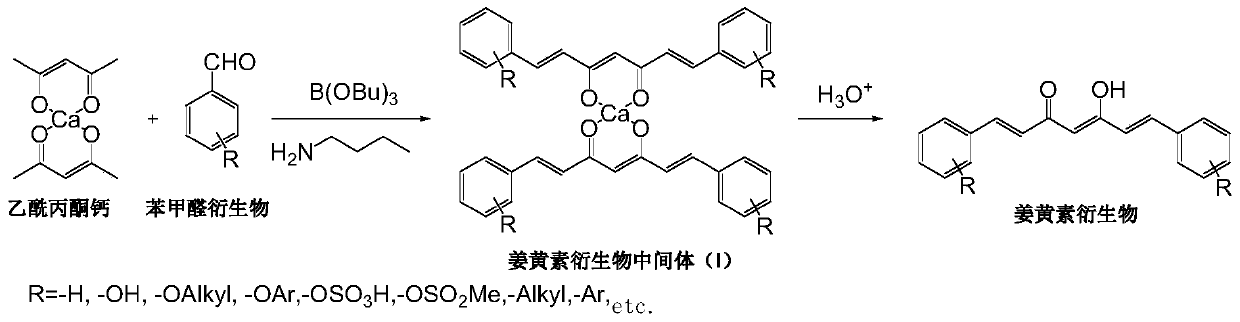

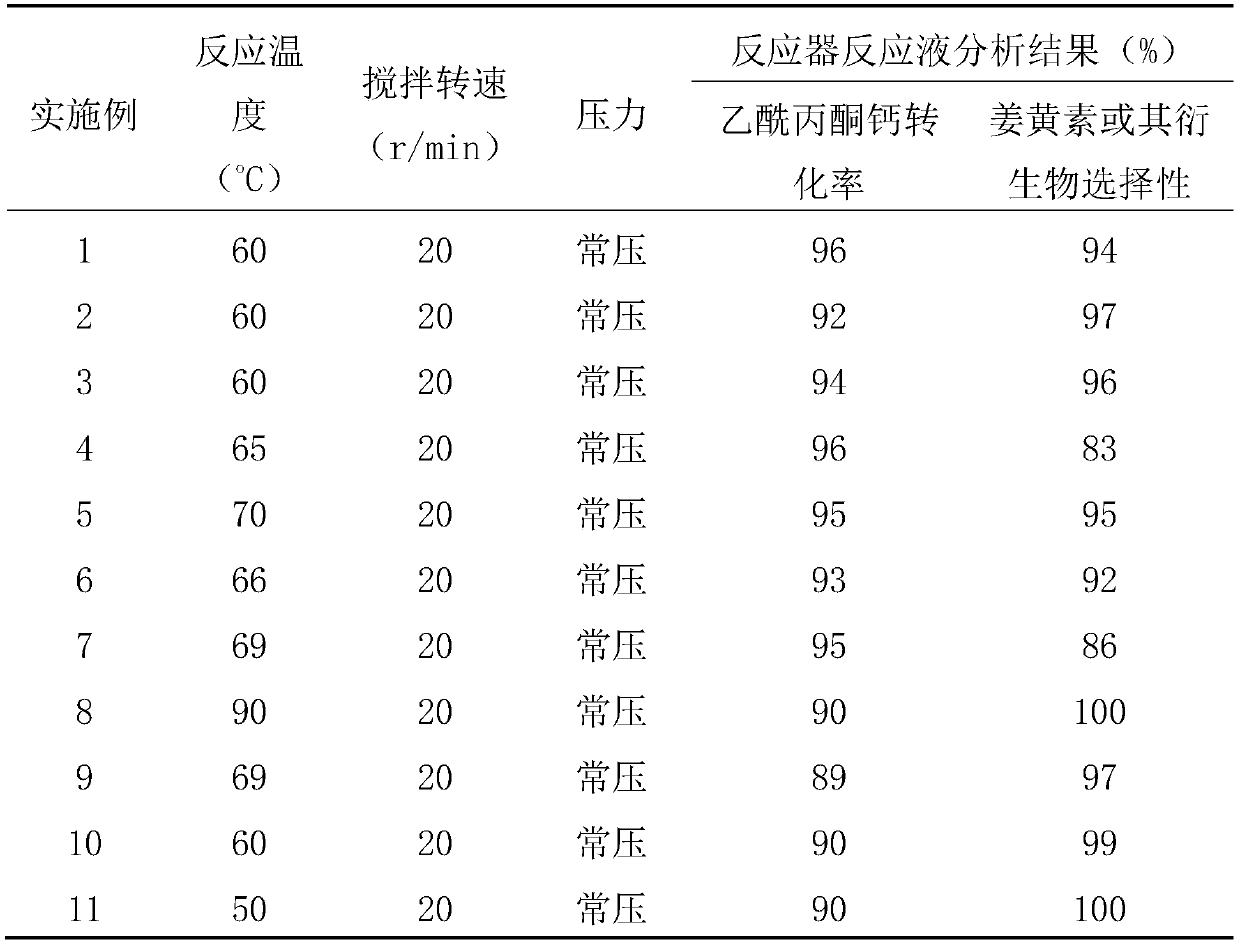

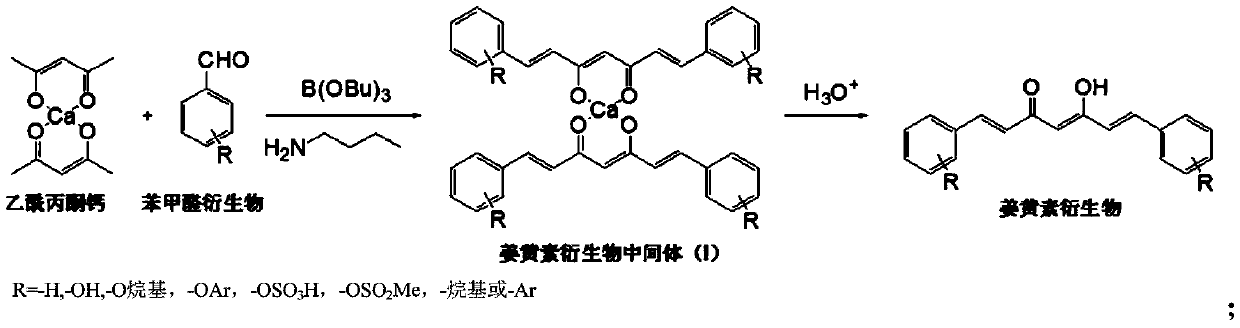

A method for artificially synthesizing curcumin and derivatives thereof

ActiveCN106748705BPrecise positioningControl amountCarbonyl compound preparation by hydrolysisPreparation of aldehyde/ketone chelatesBenzaldehydeBoronic acid

Owner:GREAT FOREST BIOMEDICAL LTD

Modified nanocellulose-polylactic acid composite film as well as preparation method and application thereof

The invention relates to a modified nanocellulose-polylactic acid composite film and a preparation method and application thereof. The modified nanocellulose-polylactic acid composite film comprises polylactic acid and nano-zinc oxide modified nanocellulose. According to the preparation method, silicotungstic acid is adopted for preparing nano-zinc oxide, and the nano-zinc oxide is loaded on the nanocellulose, so the problem that the nano-zinc oxide is easy to agglomerate is solved; and the nano-zinc oxide is compounded with polylactic acid through a solution pouring method to prepare the composite film. The composite film prepared by the invention not only has the same advantages of high mechanical strength, strong plasticity, easy processing and molding and the like as polylactic acid, but also improves the mechanical properties of a polylactic acid film; and the composite film has excellent tensile properties, obviously enhanced impact resistance and heat resistance and good antibacterial properties and moisture-permeable barrier properties, and shows wide application prospects in the field of food packaging.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com