Industrial production method of rice protein hydrolysate for feed

A technology of hydrolyzed protein and production method, which is applied in the fields of application, animal husbandry, animal feed, etc., can solve the problems of failure to realize industrial production, enzyme preparation with many single components, and no scale-up test research, etc., to achieve scientific and reasonable production technology, improve The effect of strong growth performance and comprehensive production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

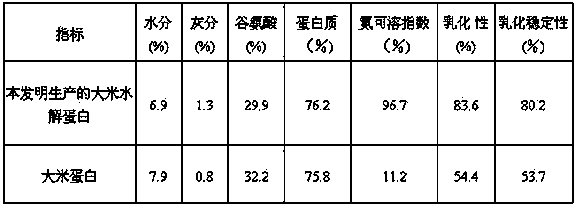

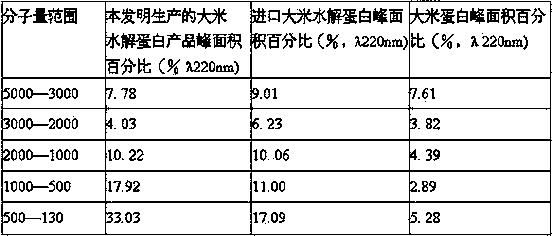

Examples

Embodiment 1

[0030]Weigh 1000kg of rice protein powder, mix it with 6000kg of warm water at 40°C in a reaction kettle, add alkaline protease to dissolve, and the added amount is 20U / g rice protein powder; then adjust the pH value to 7.5 with sodium hydroxide solution, and add the compound enzyme preparation , so that the mass percentage concentration in the solution is 0.3%, hydrolyzed at a temperature of 40°C for 3h, the compound enzyme preparation used is: alkaline protease, neutral protease, papain, flavor protease in 1:1:0.2:0.2 parts by weight compounded. Then carry out enzyme inactivation, filtration, decolorization, and spray drying treatment. Activated carbon is used for filtration and decolorization, and its addition amount is 2% of the weight of rice protein powder, and the decolorization treatment is performed at 50-90 ° C for 10-130 minutes. The inlet air temperature is 160°C, the outlet air temperature is 85°C, and the homogeneous pressure is 30MPa for spray drying to obtain t...

Embodiment 2

[0032] Weigh 1,000kg of rice protein powder, mix it with 7,000kg of warm water at 35°C in a reaction kettle, add alkaline protease to dissolve, and the added amount is 40U / g rice protein powder; then adjust the pH value to 7.0 with potassium hydroxide solution, and add a compound enzyme preparation , so that the mass percent concentration in the solution is 0.2%, hydrolyzed at a temperature of 45°C for 6h, the compound enzyme preparation used is: alkaline protease, neutral protease, papain, flavor protease in 1: 1.5: 0.3: 0.1 parts by weight compounded. Then carry out enzyme inactivation, filtration, decolorization, and spray drying treatment. Activated carbon is used for filtration and decolorization, and its addition amount is 3% of the weight of rice protein powder, and the decolorization treatment is performed at 50-90°C for 10-130min. The inlet air temperature is 150°C, the outlet air temperature is 75°C, and the homogeneous pressure is 25MPa to carry out spray drying to ...

Embodiment 3

[0034] Weigh 1000kg of rice protein powder, mix it with 5000kg of warm water at 40°C in a reaction kettle, add alkaline protease to dissolve, and the addition amount is 30U / g rice protein powder; then adjust the pH value to 6.5 with phosphoric acid, add a compound enzyme preparation to make it The mass percent concentration in the solution is 0.6%, and it is hydrolyzed at a temperature of 40°C for 4 hours; the compound enzyme preparation used is: alkaline protease, neutral protease, papain, flavor protease compounded in 1:1.3:0.5:0.1 parts by weight become. Then carry out enzyme inactivation and filtration, decolorization, spray drying treatment, filter decolorization adopts active carbon, its addition amount is 4% of rice protein powder weight, decolorization treatment 10-130min at 50-90 ℃. The inlet air temperature is 160°C, the outlet air temperature is 80°C, and the homogeneous pressure is 20MPa for spray drying to obtain the rice protein hydrolyzate for feeding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com