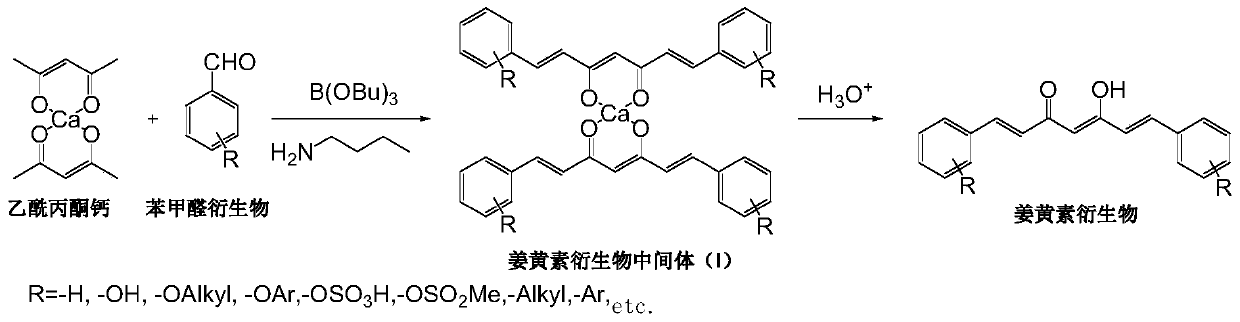

A method for artificially synthesizing curcumin and derivatives thereof

A curcumin derivative, artificial synthesis technology, applied in the field of medicine, can solve the problems of difficult continuous production, unstable active site selectivity, low production efficiency, etc., and achieves a simple post-processing method, stable properties, and less three wastes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

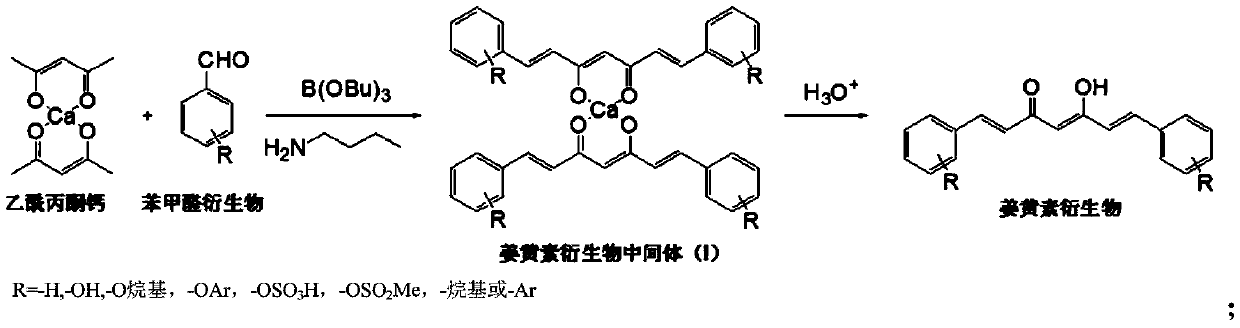

Method used

Image

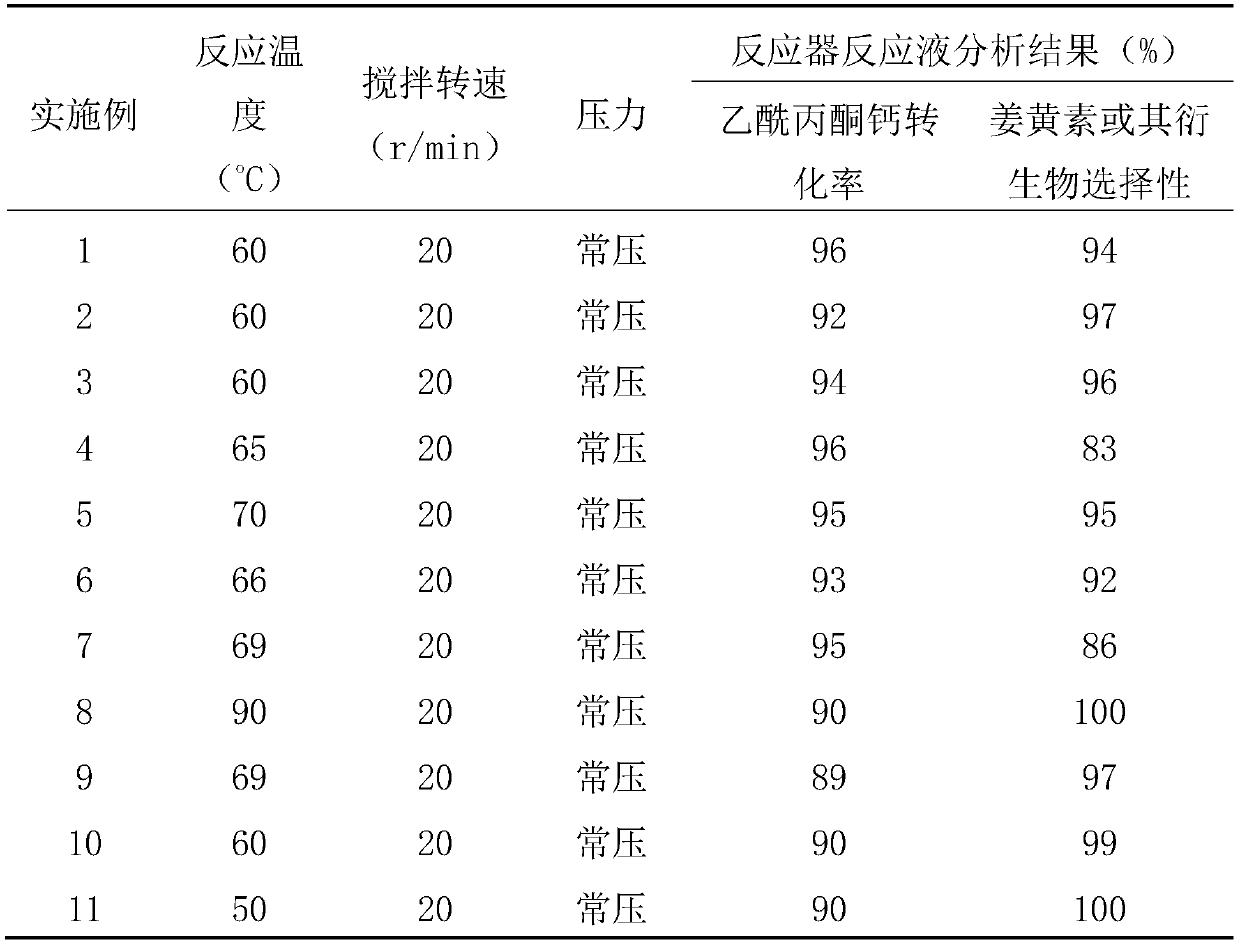

Examples

Embodiment 1

[0024] Firstly, the calcium acetylacetonate was dried in a vacuum at 60°C; the water content was measured by the Fischer reagent method, and the source of acetylacetonate-calcium acetylacetonate was obtained after passing the test.

[0025] Put 49.1Kg of calcium acetylacetonate, 125Kg of vanillin, 1500Kg of dimethylformamide, and 460Kg of tri-n-butyl borate into the reactor, raise the temperature to 55°C, and stir to dissolve. Heat 15Kg of n-butylamine to 40°C with a heater, drop it into the reactor within 30 minutes, react at a reaction temperature of 60°C, a stirring speed of 20r / min, and normal pressure. The reaction hydraulic pressure after the reaction is put into the hydrolysis tank, add 1500Kg water, adjust pH=5, stir and hydrolyze at room temperature for 12h, discharge and centrifuge; after centrifugation, the curcumin crude product is obtained, and the curcumin fine product 136.7Kg is obtained after drying, with a yield of 90%. 99% pure. The product is packaged in th...

Embodiment 2

[0028] Firstly, the calcium acetylacetonate was dried in a vacuum at 60°C; the water content was measured by the Fischer reagent method, and the source of acetylacetonate-calcium acetylacetonate was obtained after passing the test.

[0029] Put 49.1Kg of calcium acetylacetonate, 166Kg of isovanillin, 1500Kg of dimethylformamide, and 460Kg of tri-n-butyl borate into the reactor, raise the temperature to 88°C, and stir to dissolve. Heat 15Kg of n-butylamine to 40°C with a heater, drop it into the reactor within 30 minutes, react at a reaction temperature of 60°C, a stirring speed of 20r / min, and normal pressure. After the reaction, the reaction pressure is put into the hydrolysis tank, 3000Kg of water is added, the pH is adjusted to 5, the hydrolysis is stirred at room temperature for 12 hours, and the material is discharged and centrifuged; after centrifugation, the crude product of isovanillin-curcumin is obtained, and after drying, the refined product of isovanillin-curcumin 1...

Embodiment 3

[0032] Firstly, the calcium acetylacetonate was dried in a vacuum at 60°C; the water content was measured by the Fischer reagent method, and the source of acetylacetonate-calcium acetylacetonate was obtained after passing the test.

[0033] Put 49.1Kg of calcium acetylacetonate, 168Kg of p-hydroxybenzaldehyde, 1500Kg of dimethylformamide, and 460Kg of tri-n-butyl borate into the reactor, raise the temperature to 68°C, and stir to dissolve. Heat 15Kg of n-butylamine to 40°C with a heater, drop it into the reactor within 30 minutes, react at a reaction temperature of 60°C, a stirring speed of 20r / min, and normal pressure. After the reaction, the reaction pressure is put into the hydrolysis tank, 3500Kg of water is added, the pH is adjusted to 5, stirred and hydrolyzed at room temperature for 12 hours, and the material is discharged and centrifuged; after centrifugation, the crude product of bisdemethoxycurcumin is obtained, and bisdemethoxycurcumin is obtained after drying The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com