Threonine fermentation medium prepared from microbial protein

A technology of fermentation medium and bacterial protein, applied in the direction of fermentation, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of low degree of hydrolysis, achieve high hydrolysis efficiency, accelerate mass transfer process, and improve protein dissolution The effect of sex and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A process for combined hydrolysis of bacterial protein and soybean protein, which includes the following steps:

[0032] Method of obtaining bacterial protein: Use a high-speed disc separator to separate the bacterial protein in the threonine fermentation broth, recover the bacterial protein, and dry.

[0033] Take the bacterial protein and soy protein according to the weight ratio of 2:1, and then add the citric acid aqueous solution with a concentration of 0.6M according to the ratio of 1g:10ml, stir it evenly, and then place it in a high-speed shearing machine and cut for 90s at a speed of 10000rpm. Let stand for 60 minutes, then ultrasonic treatment for 60 seconds, the ultrasonic frequency is 25kHz, and then stand for 2h, then adjust the pH to 3.0, the temperature to 40℃, and add acid protease, the addition amount is 2000U / g dry matter, the enzymatic hydrolysis time is 5h , Then adjust the pH to 7.0, the temperature to 50 ℃, and then add serrapeptidase, the addition amou...

Embodiment 2

[0035] A process for combined hydrolysis of bacterial protein and soybean protein, which includes the following steps:

[0036] Take the bacterial protein and soy protein according to the weight ratio of 3:1, and then add the citric acid aqueous solution with a concentration of 0.6M according to the ratio of 1g:8ml, stir evenly, and then place it in a high-speed shearing machine and cut for 120s at a speed of 8000rpm. Let stand for 90 minutes, then ultrasonic treatment for 45s, ultrasonic frequency is 25kHz, then stand for 2h, then adjust pH to 3.0, temperature to 40℃, add acid protease, add 2000U / g dry matter, enzymolysis time is 6h , Then adjust the pH to 7.0, the temperature to 50°C, and then add serrapeptidase, the addition amount is 1000U / g dry matter, the enzymolysis time is 4h, and finally the enzyme is inactivated at 100°C for 5min to obtain the hydrolysate.

Embodiment 3

[0044] Index detection method: Kjeldahl method to determine the total protein; SDS-PAGE to distinguish the molecular weight of the protein; the protein hydrolysis method uses the ninhydrin color method to determine the degree of hydrolysis.

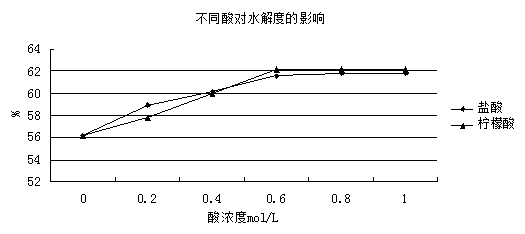

[0045] 1. The influence of different concentrations of citric acid solution and hydrochloric acid solution on the degree of hydrolysis.

[0046] Set the acid concentration gradient to 0, 0.2, 0.4, 0.6, 0.8, 1.0, the unit is mol / L; figure 1 As shown, the horizontal observation shows that as the acid concentration increases, the degree of hydrolysis also increases. When the acid concentration reaches 0.6ml / L, the degree of hydrolysis is close to the peak value. If the concentration of acid continues to increase, there is no significant effect on the degree of hydrolysis. It can damage amino acids to a certain extent. Therefore, it is most appropriate to choose a lower concentration of acid. Observed longitudinally, at a lower concentration, hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com