Preparation method of andrias oligopeptide

A technology of oligopeptides and giant salamanders, which is applied in the field of preparation of giant salamander oligopeptides, can solve problems such as unclear functions, and achieve the effects of wide application, less loss of nutrients, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

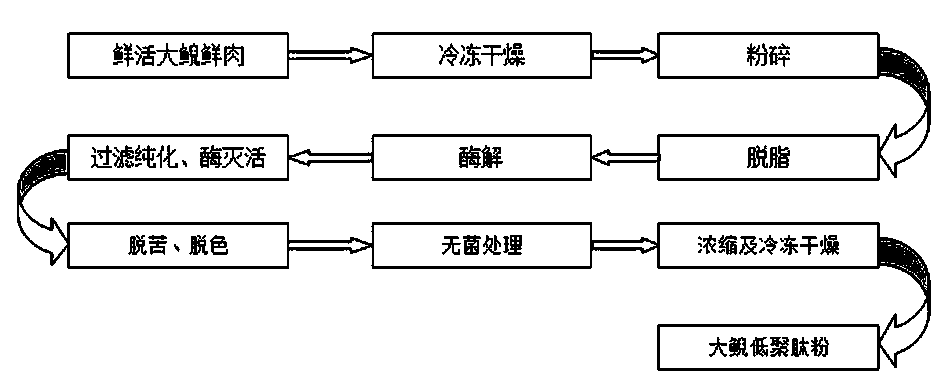

Image

Examples

Embodiment 1

[0028] 1 preprocessing

[0029] After the artificial breeding of fresh giant salamanders is slaughtered, the fresh giant salamander meat is freeze-dried and crushed to 60 mesh at 0°C to obtain giant salamander meat powder, which is put into 3 times its mass of edible oil extraction agent n-hexane The fat is removed by leaching, and the solvent is evaporated to obtain defatted giant salamander powder.

[0030] 2 enzymatic hydrolysis

[0031] The animal hydrolytic protease and neutral protease are mixed according to the mass ratio of 3:1 to form a compound enzyme. In the case of a material-to-water ratio of 1:3, 100,000 activity units of compound enzyme are added, and the amount added is 0.2% of the raw material; the compound enzyme powder is made of Hot water pretreatment, the amount of hot water is 20 times the mass of the compound enzyme powder, the temperature is 35°C, and the pretreatment time is 10 minutes; after pretreatment, stir well and filter, add to the enzymatic ...

Embodiment 2

[0041] 1 preprocessing

[0042] After slaughtering the artificially bred fresh giant salamander, take the fresh giant salamander meat, freeze-dry it, and crush it to 80 mesh at -2°C to obtain giant salamander meat powder, which is put into 2.5 times its mass of edible oil extraction agent Zhengji The fat is removed by leaching with alkane, and the solvent is evaporated to obtain defatted giant salamander powder.

[0043] 2 enzymatic hydrolysis

[0044] The animal hydrolytic protease and neutral protease are mixed according to the mass ratio of 3:1.2 to form a compound enzyme. In the case of 1:3.5 material-water ratio, 100,000 activity units of compound enzyme are added, and the amount added is 0.4% of the raw material; the compound enzyme powder adopts Hot water pretreatment, the amount of hot water is 30 times the mass of the compound enzyme powder, the temperature is 40 ° C, the pretreatment time is 12 minutes; after pretreatment, stir well and filter, add to the enzymati...

Embodiment 3

[0054] 1 preprocessing

[0055] After slaughtering the artificially bred fresh giant salamander, take the fresh giant salamander meat, freeze-dry it, and crush it to 80 mesh at -4°C to obtain giant salamander meat powder, which is put into edible oil extractant Zhengji with twice its mass. The fat is removed by leaching with alkane, and the solvent is evaporated to obtain defatted giant salamander powder.

[0056] 2 enzymatic hydrolysis

[0057] The animal hydrolytic protease and neutral protease are mixed according to the mass ratio of 3:1.4 to form a compound enzyme. In the case of a material-to-water ratio of 1:3, 100,000 activity units of the compound enzyme are added, and the amount added is 0.5% of the raw material; the compound enzyme powder is made of Hot water pretreatment, the amount of hot water is 25 times the mass of the compound enzyme powder, the temperature is 45°C, and the pretreatment time is 15 minutes; after pretreatment, stir and filter, add to the enzy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com