Method for preparing organic-inorganic hybrid film

A hybrid membrane, inorganic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Easy to control and adjust, good acid resistance, avoid cracks or peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

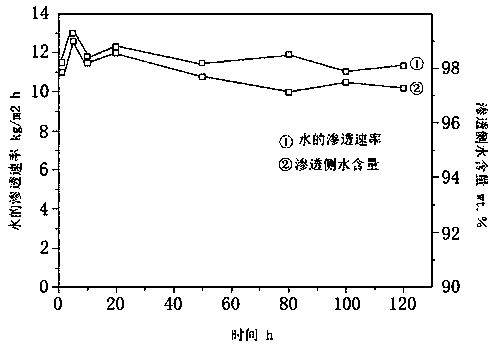

Embodiment 1

[0030] A method for preparing an organic-inorganic hybrid membrane, specifically comprising the following steps:

[0031] Step 1: After diluting 10ml of methyltriethoxysilane (MTES) into absolute ethanol, gradually add 5ml of deionized water and 6ml of ammonia water (NH3.H2O, 37%) dropwise as a catalyst to adjust the pH of the hydrolysis. Heat the solution to 40-70°C while fully stirring, and stir vigorously at a constant temperature for 12 hours, let the solution fully hydrolyze and then drop to room temperature to form a sol solution with relatively single particle dispersion. The average particle size of the colloid is 4.8nm after analysis. ;

[0032] Step 2: Add a small amount of organic polymers, such as polyvinyl alcohol (PVA), to the sol solution to change the viscosity of the sol to 2.5-5.5Pa.s, and add an appropriate amount of plasticizer, such as polyethylene glycol (PEG), to adjust the plasticity of the sol;

[0033] Step 3: Apply the sol to the multi-layer suppor...

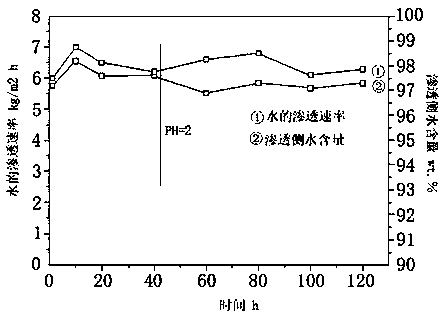

Embodiment 2

[0037]A method for preparing an organic-inorganic hybrid membrane, specifically comprising the following steps:

[0038] Step 1: After diluting 10ml of ethyltriethoxysilane (ETES) into absolute ethanol, gradually add 5ml of deionized water and 8ml of lysine (20wt.% aqueous solution) dropwise as catalysts to adjust the pH of the hydrolysis, Heat the solution to 40-70°C while fully stirring, and stir vigorously at a constant temperature for 8 hours to allow the solution to fully hydrolyze and then drop to room temperature to form a sol solution with relatively single particle dispersion. The average particle size of the colloid is 4.8nm after analysis. ;

[0039] Step 2: Add a small amount of organic polymers, such as polyvinyl alcohol (PVA), to the sol solution to change the viscosity of the sol to 2.5-5.5Pa.s, and add an appropriate amount of plasticizer, such as polyethylene glycol (PEG), to adjust the plasticity of the sol;

[0040] Step 3: Apply the sol to the multi-layer...

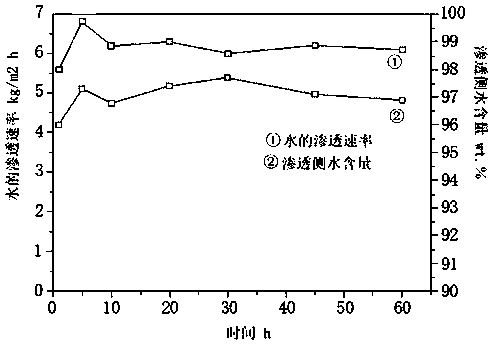

Embodiment 3

[0044] A method for preparing an organic-inorganic hybrid membrane, specifically comprising the following steps:

[0045] Step 1: After diluting 10ml of methyltriethoxysilane (MTES) into absolute ethanol, gradually dropwise add 5ml of deionized water and 30% acetic acid solution as a catalyst to adjust the pH of the hydrolysis, while fully stirring Heat the solution to 40-70°C, and stir vigorously at constant temperature for 16 hours, let the solution fully hydrolyze and then cool down to room temperature to form a sol solution with relatively single particle dispersion. The average particle size of the colloid is 4.8nm after analysis;

[0046] Step 2: Add a small amount of organic polymers, such as polyvinyl alcohol (PVA), to the sol solution to change the viscosity of the sol to 2.5-5.5Pa.s, and add an appropriate amount of plasticizer, such as polyethylene glycol (PEG), to adjust the plasticity of the sol;

[0047] Step 3: Apply the sol to the multi-layer support by dip co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Water permeability | aaaaa | aaaaa |

| Water permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com