A method for preparing activated carbon and furfural from corn cobs

A technology for preparing activated carbon and corn cobs, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as economic waste and environmental pollution, and achieve the effects of increasing yield, reducing production costs, and reducing production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

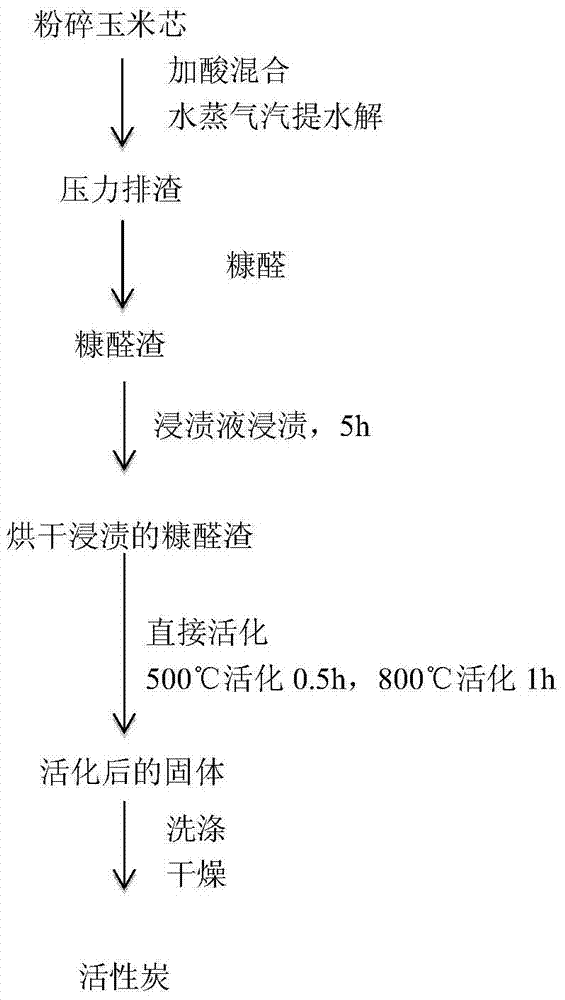

Method used

Image

Examples

Embodiment 1

[0039] The raw corncobs are purchased from the market and air-dried naturally, with a water content of 7%.

[0040] Corn cobs are crushed to a particle size of 15 mm to 20 mm, mixed with sulfuric acid solution, the mass concentration of the sulfuric acid solution is 15%, and the dosage of the sulfuric acid solution is 0.29 kg / (kg corn cobs).

[0041] The mixture of corncob and sulfuric acid is put into a hydrolysis reactor for stripping and hydrolysis, and water vapor passes through the bed of corncob sulfuric acid mixture from bottom to top; the steam temperature is 175°C, and the hydrolysis time is 2h (the contact time between water vapor and corncob reaches 2 hours , continuous exhaust). Furfural gas is collected during stripping, hydrolysis and pressure slagging, condensed and distilled to obtain furfural products.

[0042] The hydrolysis residue obtained from the stripped corn cob sulfuric acid mixture is furfural residue, and the hydrolysis residue is discharged from th...

Embodiment 2

[0046] The raw corncobs are purchased from the market and air-dried naturally, with a water content of 6%.

[0047] Corn cobs are crushed to a particle size between 15 mm and 20 mm, mixed with acid, the mass concentration of sulfuric acid is 10%, and the amount of sulfuric acid is 0.20 kg / (kg corn cobs). Stripping hydrolysis, steam temperature 172 ℃, hydrolysis time 1.5h. Furfural gas is collected during stripping, hydrolysis and pressure slagging, condensed and distilled to obtain furfural products. Furfural slag impregnation, 30% mass concentration of KOH solution and furfural slag 1:1 mixed, impregnated at room temperature for 5h, impregnated furfural slag and dried without free water. Impregnated with furfural slag and activated directly, activated at 500°C for 0.5h, activated at 800°C for 1h to obtain a solid. The solid is washed and dried to obtain an activated carbon product. Operations not particularly described are the same as in Example 1.

[0048] The yield of f...

Embodiment 3

[0050] Corn cobs are crushed to a particle size of 15 mm to 20 mm, mixed with acid, the mass concentration of sulfuric acid is 13%, and the amount of sulfuric acid is 0.25 kg / (kg corn cobs). Stripping hydrolysis, steam temperature 174 ℃, hydrolysis time 2h. Furfural gas is collected during stripping, hydrolysis and pressure slagging, condensed and distilled to obtain furfural products. Furfural slag impregnation, 40% mass concentration of KOH solution and furfural slag 1:1 mixed, impregnated at room temperature for 5h, impregnated furfural slag and dried without free water. Impregnated with furfural slag and activated directly, activated at 500°C for 0.5h, activated at 800°C for 1h to obtain a solid. The solid is washed and dried to obtain an activated carbon product. Operations not particularly described are the same as in Example 1.

[0051] The yield of furfural is 15.2%, the yield of activated carbon is 24.9%, and the specific surface area is 1950.2m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com