Preparation of zirconia superfine powder by hydrolysis method

A technology of ultra-fine powder and zirconia, which is used in the field of inorganic chemical synthesis and new materials, can solve the problems of complex post-processing process, and achieve the effect of narrow particle size distribution, short hydrolysis time and excellent sintering performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

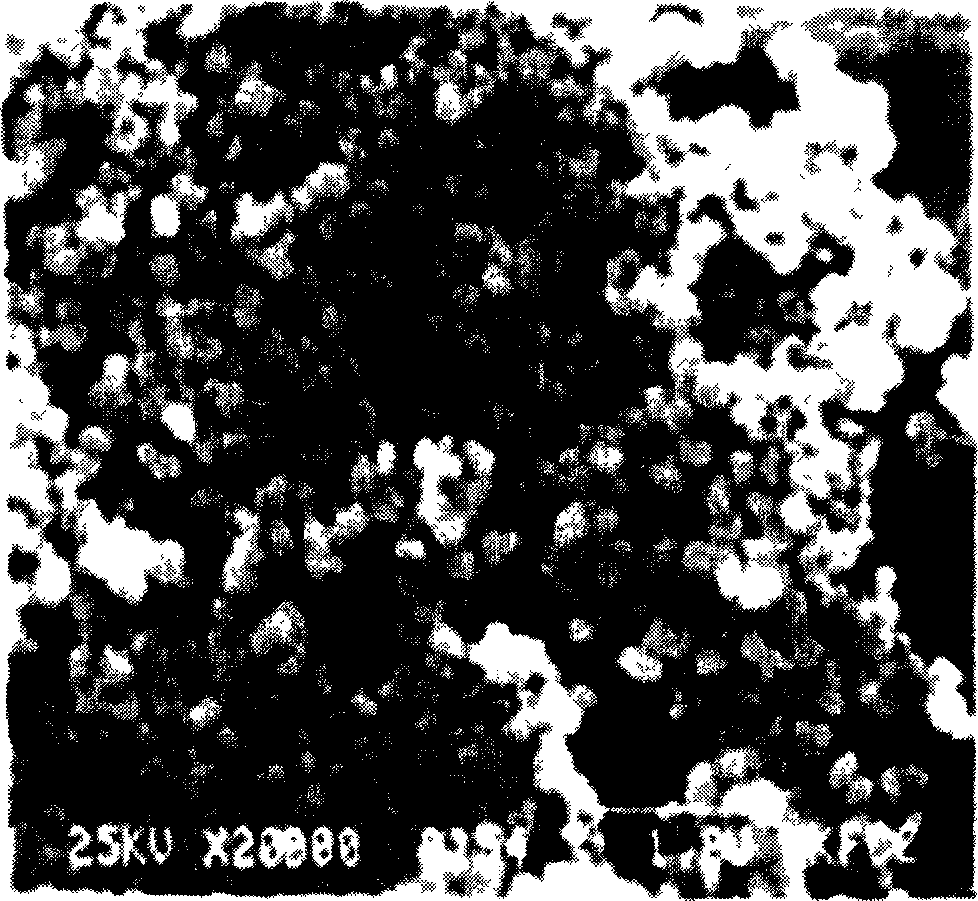

Image

Examples

Embodiment 1

[0012] Weigh 100g of zirconium oxychloride crystals (purity 99.5%) and dissolve them in 950ml of water to form a 0.31mol / L zirconium oxychloride aqueous solution; slowly add 17% ammonia water to the zirconium oxychloride solution dropwise under stirring, when the pH of the solution When the value reaches 2.0, stop adding ammonia water dropwise; add 100mL of 30% hydrogen peroxide solution under stirring, then raise the temperature until the solution boils, keep it for 24h, end the hydrolysis reaction, and cool down to room temperature naturally; adjust the pH value to 8 with ammonia water to obtain a milky white suspension solution, filtered, and washed with distilled water until the solution has no chloride ions; after washing, add the filter cake to 800mL of absolute ethanol, stir to make an emulsion, filter, then soak in 400mL of absolute ethanol, and stir to make an emulsion Put it into the pressure reactor and heat it. When the pressure reaches 0.8MPa, start to slowly vent ...

Embodiment 2

[0014] Weigh 100g of zirconium oxychloride crystals (purity 99.5%) and dissolve them in 950mL of water to form a 0.31mol / L zirconium oxychloride aqueous solution; slowly add 17% ammonia water to the zirconium oxychloride solution dropwise under stirring, when the pH of the solution When the pH value reaches 2.2, stop adding ammonia water dropwise; add 50mL of 50% hydrogen peroxide solution under stirring, then raise the temperature until the solution boils, keep it for 24h, end the hydrolysis reaction, and naturally cool to room temperature; adjust the pH value to 9 with ammonia water to obtain a milky white suspension liquid, filtered, and washed with deionized water until the solution has no chloride ions; after washing, add the filter cake to 800mL of absolute ethanol, stir to make an emulsion, filter, then add 400mL of absolute ethanol, and stir to make an emulsion Turbid liquid; put it into a pressure reactor and heat it. When the pressure reaches 0.8MPa, start to slowly v...

Embodiment 3

[0016] Weigh 150g of zirconium oxychloride crystals (purity 99.5%) and dissolve them in 950mL of water to form a 0.46mol / L zirconium oxychloride aqueous solution; slowly add 17% ammonia water to the zirconium oxychloride solution dropwise under stirring, when the pH of the solution When the pH value reaches 1.9, stop adding ammonia water dropwise; add 150 mL of 30% hydrogen peroxide solution under stirring, then raise the temperature until the solution boils, keep it for 24 hours, end the hydrolysis reaction, and naturally cool to room temperature; adjust the pH value to 8.5 with ammonia water to obtain a milky white suspension solution, filtered, and washed with deionized water until the solution has no chloride ions; after washing, add the filter cake to 1500mL of absolute ethanol, stir until uniform, filter, then add 600mL of absolute ethanol, and stir to make an emulsion Put it into the pressure reactor and heat it. When the pressure reaches 0.8MPa, start to vent slowly to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com