Processing method of kitchen garbage

A kitchen waste and treatment method technology, applied in the field of kitchen waste treatment, can solve the problems of imperfect resource utilization technology, incomplete material fermentation, easy acidification during debugging, etc., to save human resources, simple pretreatment, and no human body. Harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the processing method of kitchen waste

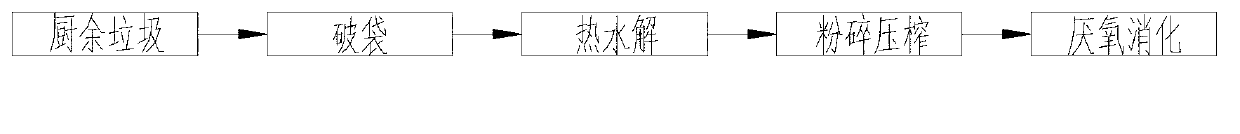

[0023] according to figure 1 The process shown is for the treatment of kitchen waste.

[0024] (1) First use a bag breaking machine to tear the plastic bag containing the garbage, release the wrapped garbage, and then transport the kitchen waste to the hydrolysis tank;

[0025] (2) Introduce saturated steam into the hydrolysis tank, and control the hydrolysis conditions: the temperature is 150°C, the pressure is 1.0MPa, and the hydrolysis is carried out for 150 minutes under the above conditions, so as to fully sterilize the garbage and achieve harmlessness. At the same time, the thermal hydrolysis step can effectively destroy the tissue structure of some substances in the kitchen waste, causing the water inside the tissue to overflow, which is more conducive to the subsequent treatment of the kitchen waste; after the thermal hydrolysis, open the thermal hydrolysis tank under a certain pressure, Expansion of the m...

Embodiment 2

[0029] Embodiment 2, the treatment method of kitchen waste

[0030] according to figure 1 The process shown is for the treatment of kitchen waste.

[0031] (1) First use a bag breaking machine to tear the plastic bag containing the garbage, release the wrapped garbage, and then transport the kitchen waste to the hydrolysis tank;

[0032] (2) Introduce saturated steam into the hydrolysis tank, and control the hydrolysis conditions: the temperature is 150°C, the pressure is 1.0MPa, and the hydrolysis is carried out for 120 minutes under the above conditions, so as to fully sterilize the garbage and achieve harmlessness. At the same time, the thermal hydrolysis step can effectively destroy the tissue structure of some substances in the kitchen waste, causing the water inside the tissue to overflow, which is more conducive to the subsequent treatment of the kitchen waste; after the thermal hydrolysis, open the thermal hydrolysis tank under a certain pressure, Expansion of the ma...

Embodiment 3

[0036] Embodiment 3, the treatment method of kitchen waste

[0037] according to figure 1 The process shown is for the treatment of kitchen waste.

[0038] (1) First use a bag breaking machine to tear the plastic bag containing the garbage, release the wrapped garbage, and then transport the kitchen waste to the hydrolysis tank;

[0039] (2) Introduce saturated steam into the hydrolysis tank, and control the hydrolysis conditions: the temperature is 150°C, the pressure is 1.0MPa, and the hydrolysis is carried out for 90 minutes under the above conditions, so as to fully sterilize the garbage and achieve harmlessness. At the same time, the thermal hydrolysis step can effectively destroy the tissue structure of some substances in the kitchen waste, causing the water inside the tissue to overflow, which is more conducive to the subsequent treatment of the kitchen waste; after the thermal hydrolysis, open the thermal hydrolysis tank under a certain pressure, Expansion of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com