Method of utilizing acidic mannase to hydrolyze refined konjac powder to prepare konjac oligosaccharide

A technology of mannanase and konjac fine powder, which is applied in the field of food processing, can solve the problems of negative impact on animal growth and production performance, inability to utilize nutrients, and affect the absorption of nutrients, etc., and achieve good health care effects, mild conditions, and simple low sugar effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

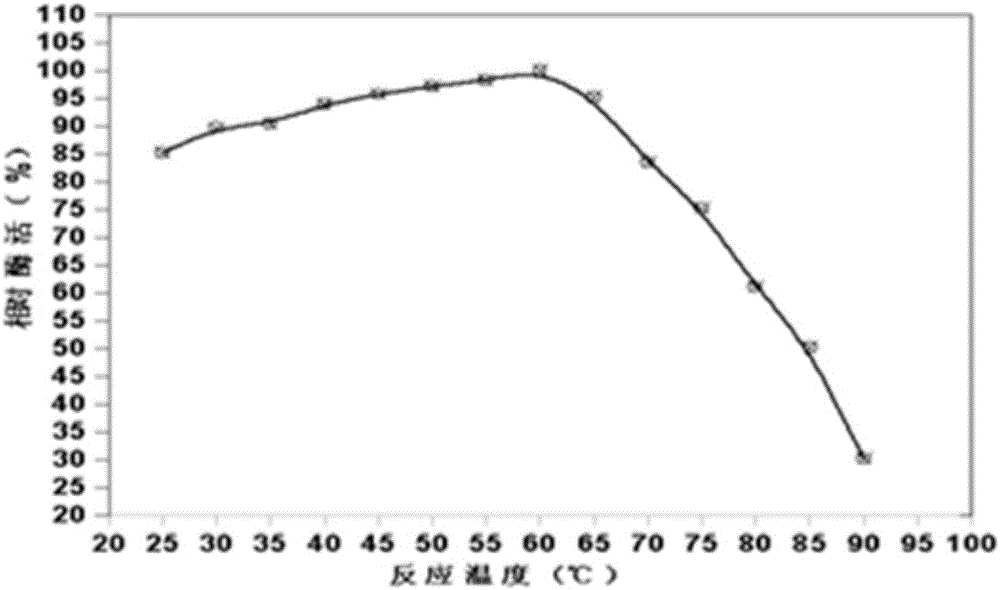

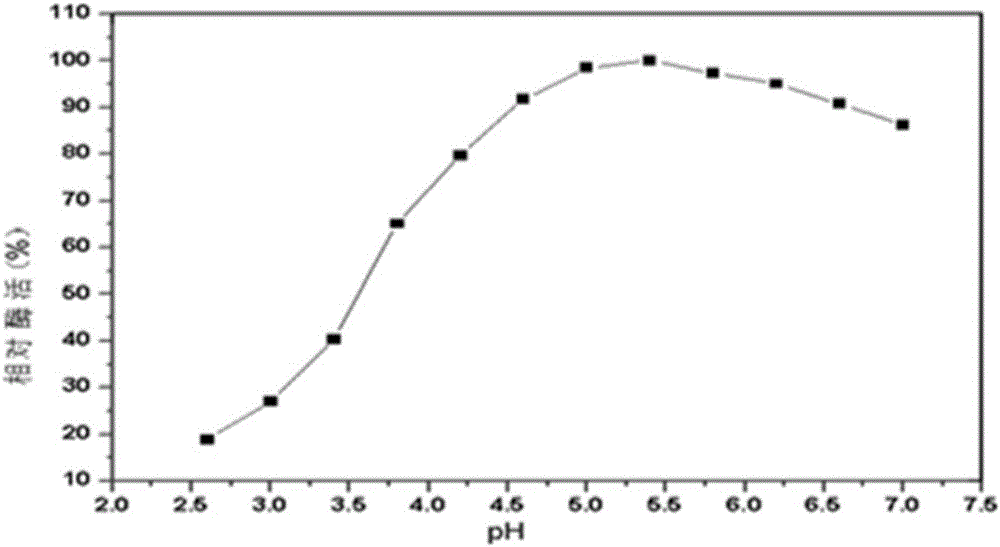

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing konjac oligosaccharides by hydrolyzing konjac powder with acid mannanase, comprising the steps of:

[0033] (1) Preparation of enzyme solution:

[0034] Add deionized water into the reaction kettle in advance, adjust the pH value of the water to 4.5 with hydrochloric acid, heat to 40°C, configure the β-mannanase aqueous solution according to the ratio of 200IU / g konjac powder, and stir and mix evenly;

[0035] (2) Hydrolysis of konjac powder:

[0036]Turn on low-speed stirring, and slowly add konjac powder into the β-mannanase aqueous solution. As the konjac powder in the reaction kettle absorbs water and expands, the viscosity increases. You can stop adding konjac powder appropriately. Once it becomes thin, continue to add konjac powder , the weight that requires to add konjac powder accounts for 15% (mass concentration) of whole reaction system, and operation requirement whole feeding time is within 20min, and enzymatic hydrolysis reaction is 6...

Embodiment 2

[0044] A method for preparing konjac oligosaccharides by hydrolyzing konjac powder with acid mannanase, comprising the steps of:

[0045] (1) Preparation of enzyme solution:

[0046] Add deionized water into the reaction kettle in advance, adjust the pH value of the water to 7.0 with acid, heat to 60°C, configure the β-mannanase aqueous solution according to the ratio of 300IU / g konjac powder, and stir and mix evenly;

[0047] (2) Hydrolysis of konjac powder:

[0048] Turn on low-speed stirring, and slowly add konjac powder into the β-mannanase aqueous solution. As the konjac powder in the reaction kettle absorbs water and expands, the viscosity increases. You can stop adding konjac powder appropriately. Once it becomes thin, continue to add konjac powder , the weight that requires to add konjac powder accounts for 25% (mass concentration) of whole reaction system, and operation requirement whole feeding time is within 20min, and enzymatic hydrolysis reaction is 60min, and hy...

Embodiment 3

[0056] A method for preparing konjac oligosaccharides by hydrolyzing konjac powder with acid mannanase, comprising the steps of:

[0057] (1) Preparation of enzyme solution:

[0058] Add deionized water into the reaction kettle in advance, adjust the pH value of the water to 5.5 with acid, heat to 50°C, configure the β-mannanase aqueous solution according to the ratio of 250IU / g konjac powder, stir and mix evenly;

[0059] (2) Hydrolysis of konjac powder:

[0060] Turn on low-speed stirring, and slowly add konjac powder into the β-mannanase aqueous solution. As the konjac powder in the reaction kettle absorbs water and expands, the viscosity increases. You can stop adding konjac powder appropriately. Once it becomes thin, continue to add konjac powder , the weight that requires to add konjac powder accounts for 20% (mass concentration) of whole reaction system, and operation requirement whole feeding time is within 20min, and enzyme hydrolysis reaction is 60min, and hydrolysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com