Preparation method and application of BiOI nanoflower with three-dimensional layered structure

A three-dimensional layered, nano-flower technology, applied in chemical instruments and methods, inorganic chemistry, water treatment of special compounds, etc., can solve the problems of difficult control of reaction conditions, unfavorable scaled production, complex operating conditions, etc., and achieves easy scale-up. Production, excellent visible light catalytic degradation of industrial dyes and antibiotic properties, the effect of short hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The preparation method of the BiOI nanoflower with three-dimensional layered structure in this embodiment is realized through the following steps:

[0026] Step 1. Add 2mmol of bismuth nitrate pentahydrate into 32mL of ethylene glycol and stir for 0.5h, then add 2mmolHI, stir thoroughly for 0.5h, transfer to a high-pressure reactor with a polytetrafluoroethylene liner, and react at 200°C for 0.5h. Cool at room temperature to obtain a clear solution;

[0027] Step 2: After adding 32 mL of water, a yellow solid precipitate appeared immediately, and the solid was separated by suction filtration. The obtained solid compound was washed three times with water and absolute ethanol, and dried at 60°C to obtain BiOI nanoflowers.

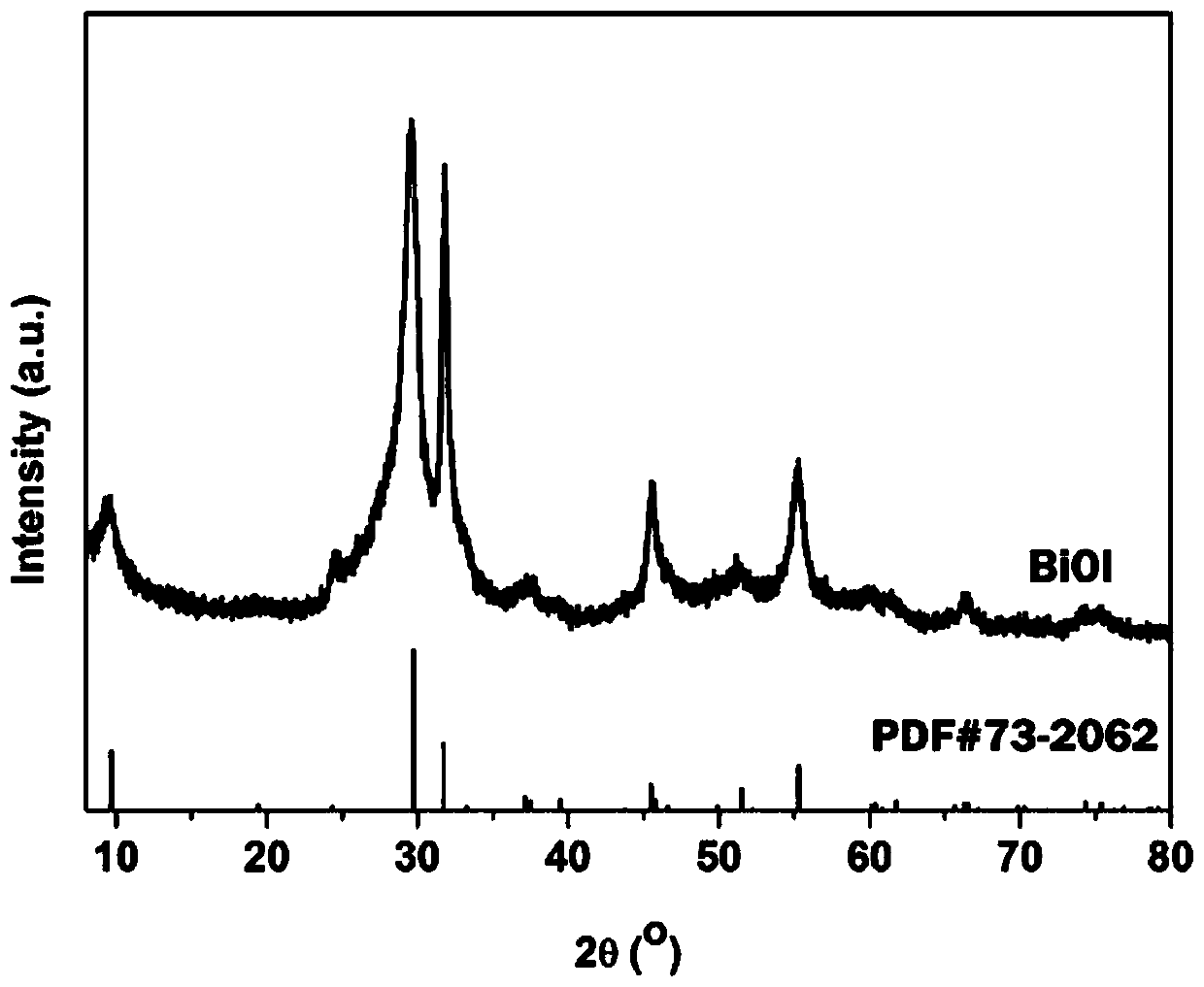

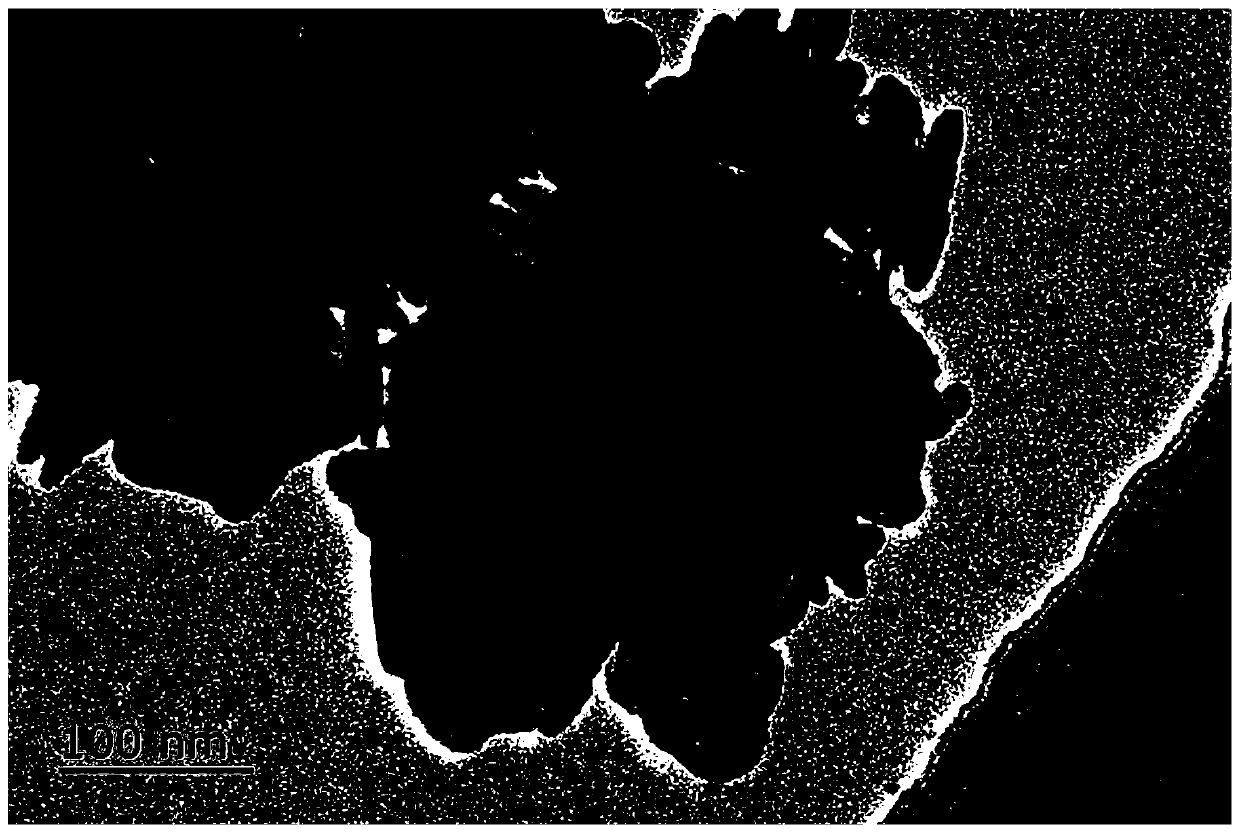

[0028] figure 1 It is the X-ray powder diffraction test picture of BiOI nanoflowers. It can be seen from the figure that the X-ray derivative peak of the prepared solid powder is completely consistent with the standard card JCPDS: 73-20...

Embodiment 2

[0029] Embodiment 2: The preparation method of the BiOI nanoflower with three-dimensional layered structure in this embodiment is realized through the following steps:

[0030] Step 1. Add 2mmol of bismuth nitrate pentahydrate into 16mL of ethylene glycol and stir for 0.5h, then add 2mmolHI, stir thoroughly for 0.5h, then transfer to a high-pressure reactor with a polytetrafluoroethylene liner, react at 120°C for 2h, room temperature Cool to obtain a clear solution;

[0031] Step 2, then add 40mL of water to immediately appear a yellow solid precipitate, the solid is separated by suction filtration, the obtained solid compound is washed three times with water and absolute ethanol, and dried at 60°C to obtain BiOI nanoflowers.

Embodiment 3

[0032] Embodiment 3: The preparation method of the BiOI nanoflower with three-dimensional layered structure in this embodiment is realized through the following steps:

[0033] Step 1. Add 2mmol of bismuth nitrate pentahydrate into 64mL of methanol and stir for 1h, then add 2mmol of HI, stir thoroughly for 1h, then transfer to a high-pressure reactor with a polytetrafluoroethylene liner, react at 140°C for 1h, and cool at room temperature to obtain clarification solution;

[0034] Step 2, then add 128mL of water and immediately appear a yellow solid precipitate, the solid is separated by suction filtration, the obtained solid compound is washed 3 times with water and absolute ethanol, and dried at 60°C to obtain BiOI nanoflowers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com