High pressure continuous hydrolysis technology for grease

A technology of oil and high pressure, which is applied in the field of oil hydrolysis to produce fatty acids, which can solve the problems of long production cycle, low degree of hydrolysis, and large investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

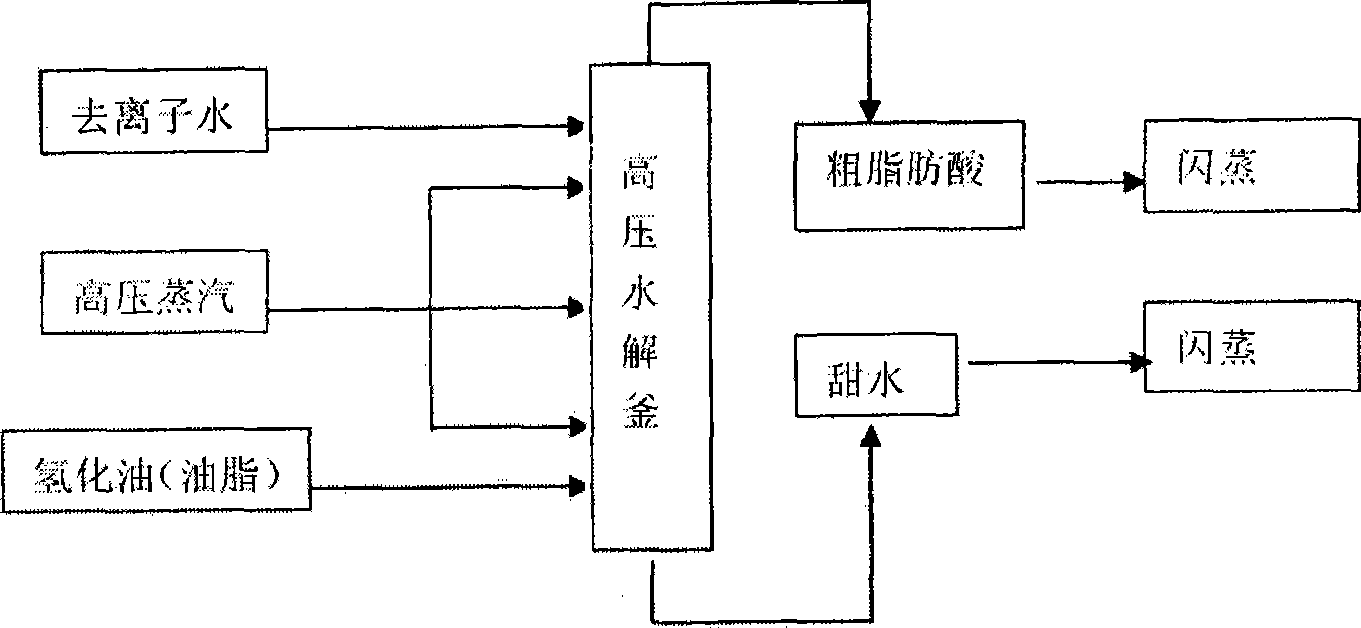

[0020] As shown in the figure, the raw material deionization is continuously sent into the hydrolysis tower by the high-pressure pump. After the raw material water drops and exchanges heat with the fatty acid liquid layer, it continues to drop. Continuously entering the hydrolysis tower, the raw oil and fat enter the continuous phase through the oil-water interface after heat exchange with the hydrolyzed glycerin water during the rising process. Control the intake of high-pressure steam through the regulating valve, so that the temperature in the hydrolysis tower is controlled at 200°C, and the pressure is controlled at 4.8MPa. The liquid phase oil in the ascending process and the liquid phase water in the descending process are hydrolyzed in countercurrent contact in the tower Reaction, the reacted crude fatty acid is discharged from the top of the tower into the flash tank for degassing, and the sweet water is discharged from the bottom of the tower into the flash tank for de...

Embodiment 2

[0022] As shown in the figure, the raw material deionized water is continuously sent into the hydrolysis tower by the high-pressure pump. After the raw material water drops and exchanges heat with the fatty acid liquid phase layer, it continues to drop. Continuously entering the hydrolysis tower, the raw oil and fat enter the continuous phase through the oil-water interface after heat exchange with the hydrolyzed glycerin water during the rising process. The intake of high-pressure steam is controlled by the regulating valve, so that the temperature in the hydrolysis tower is controlled at 260°C and the pressure is controlled at 5.0MPa. The liquid phase oil in the ascending process and the liquid phase water in the descending process are hydrolyzed in countercurrent contact in the tower Reaction, the reacted crude fatty acid is discharged from the top of the tower into the flash tank for degassing, and the sweet water is discharged from the bottom of the tower into the flash ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com