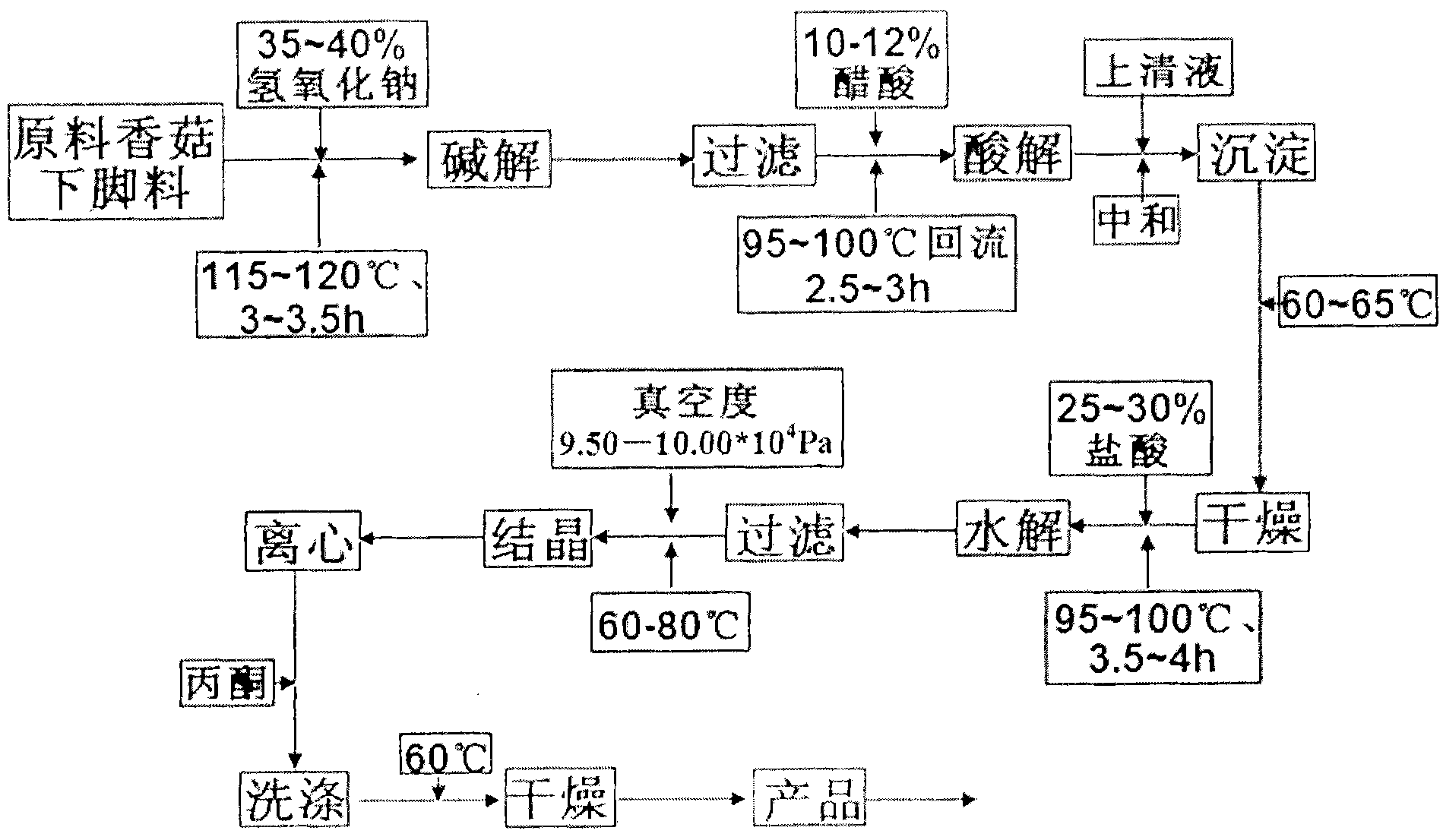

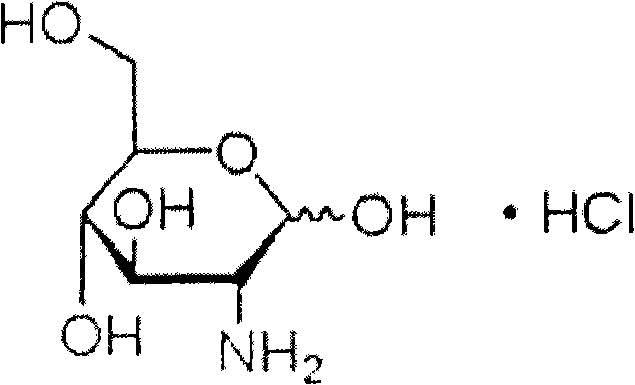

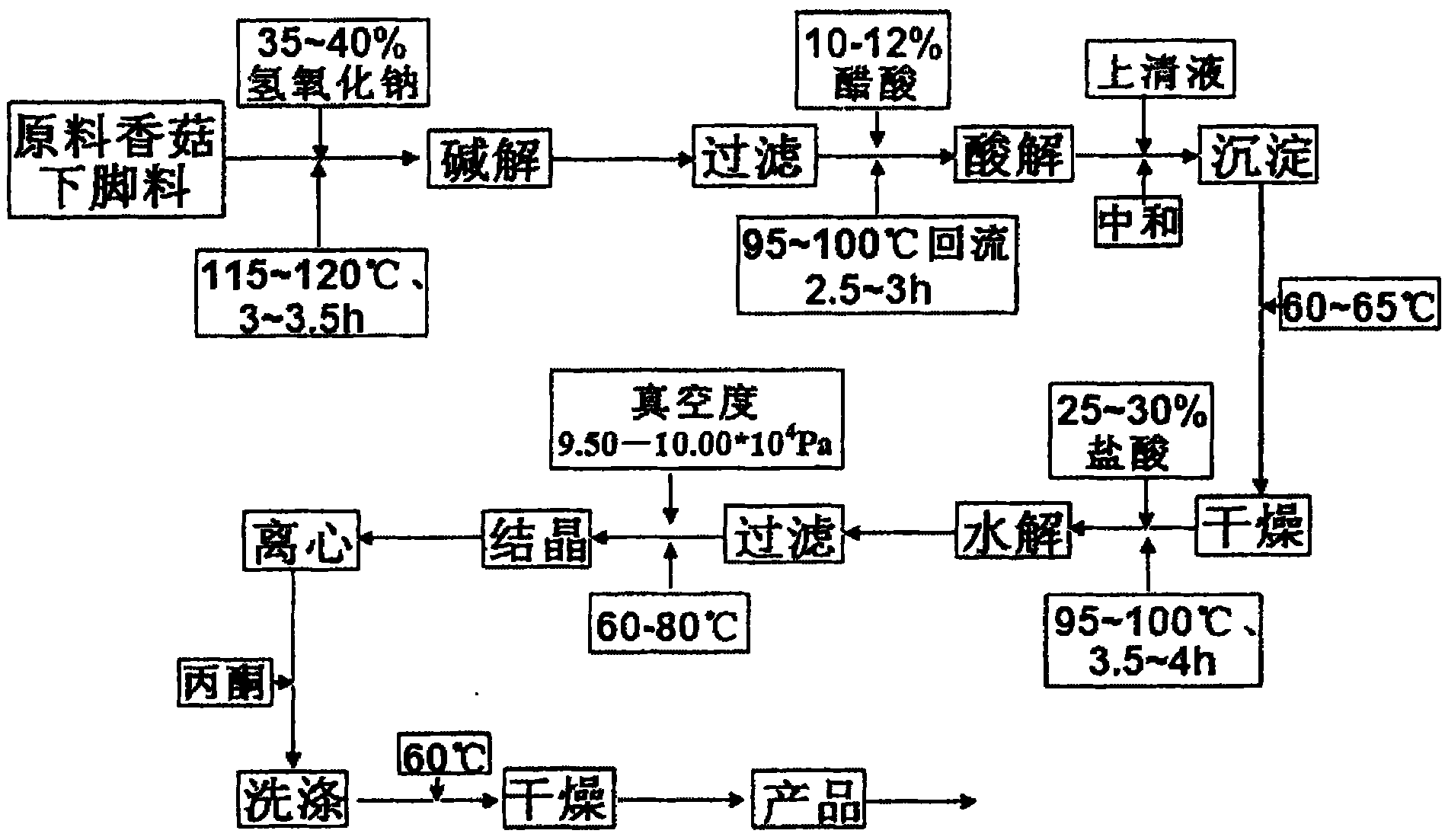

Method for separating glucosamine hydrochloride from Lentinus edodes leftovers

A technology for glucosamine hydrochloride and shiitake mushroom leftovers, which is applied in the field of separation of glucosamine hydrochloride, can solve the problems of difficult process implementation and industrialization, and achieve simple and feasible technical route, high yield and short hydrolysis time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dry 500g of lentinus stalks, alkali hydrolyze in 5000ml of 40% sodium hydroxide solution, temperature 120℃, time 3h. Cool to 25°C, filter, wash the filter residue with 1000ml of pure water, add 5000ml of acetic acid with the raw material weight to the filter residue, the concentration of acetic acid is 10%, and heat and reflux at 95°C for 2.5h. After the solution is cooled, centrifuge at 5000r / min for 5min, and take the supernatant. Titrate the supernatant with 30% sodium hydroxide solution to make the pH of the supernatant ≥10, and white flocculent precipitates continuously precipitate during the titration process. Centrifuge at 5000r / min for 5min, and take the precipitate, and place it at 60℃. drying. Add the above precipitate to an enamel reactor, and then add 5 times the weight of the precipitate with hydrochloric acid, with a hydrochloric acid concentration of 25%; gradually increase the temperature and stir. After the temperature is raised to 95°C, heat and hydrol...

Embodiment 2

[0033] Dry 500g of lentinus stalks, alkali hydrolyze with 5000ml of 35% sodium hydroxide solution, temperature 115℃, time 3.5h. Cool to 25°C, filter, wash the filter residue with 1000ml of pure water, add 5000ml of acetic acid with the raw material weight to the filter residue, the acetic acid concentration is 12%, and heat to reflux at 100°C for 3h. After the solution is cooled, centrifuge at 5000r / min for 5min, and take the supernatant. Titrate the supernatant with 30% sodium hydroxide solution to make the pH of the supernatant ≥10. During the titration, white flocculent precipitates are continuously precipitated. Centrifuge at 5000r / min for 5min, take the precipitate, and place it at 65℃. drying. Add the above precipitate to an enamel reactor, and then add 5 times the weight of the precipitate with hydrochloric acid with a hydrochloric acid concentration of 30%; gradually increase the temperature and stir. After the temperature is raised to 100°C, heat and hydrolyze for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com