Hydrolysis method for lithium slag from lithium alkyl synthesis

A technology for alkyl lithium and lithium slag, which is applied in the field of hydrolysis of lithium slag obtained by synthesizing alkyl lithium, can solve the problems of rapid temperature and pressure rise, pressure rise of hydrolysis kettle, and combustible gas breakthrough, etc. The effect of safe hydrolysis process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

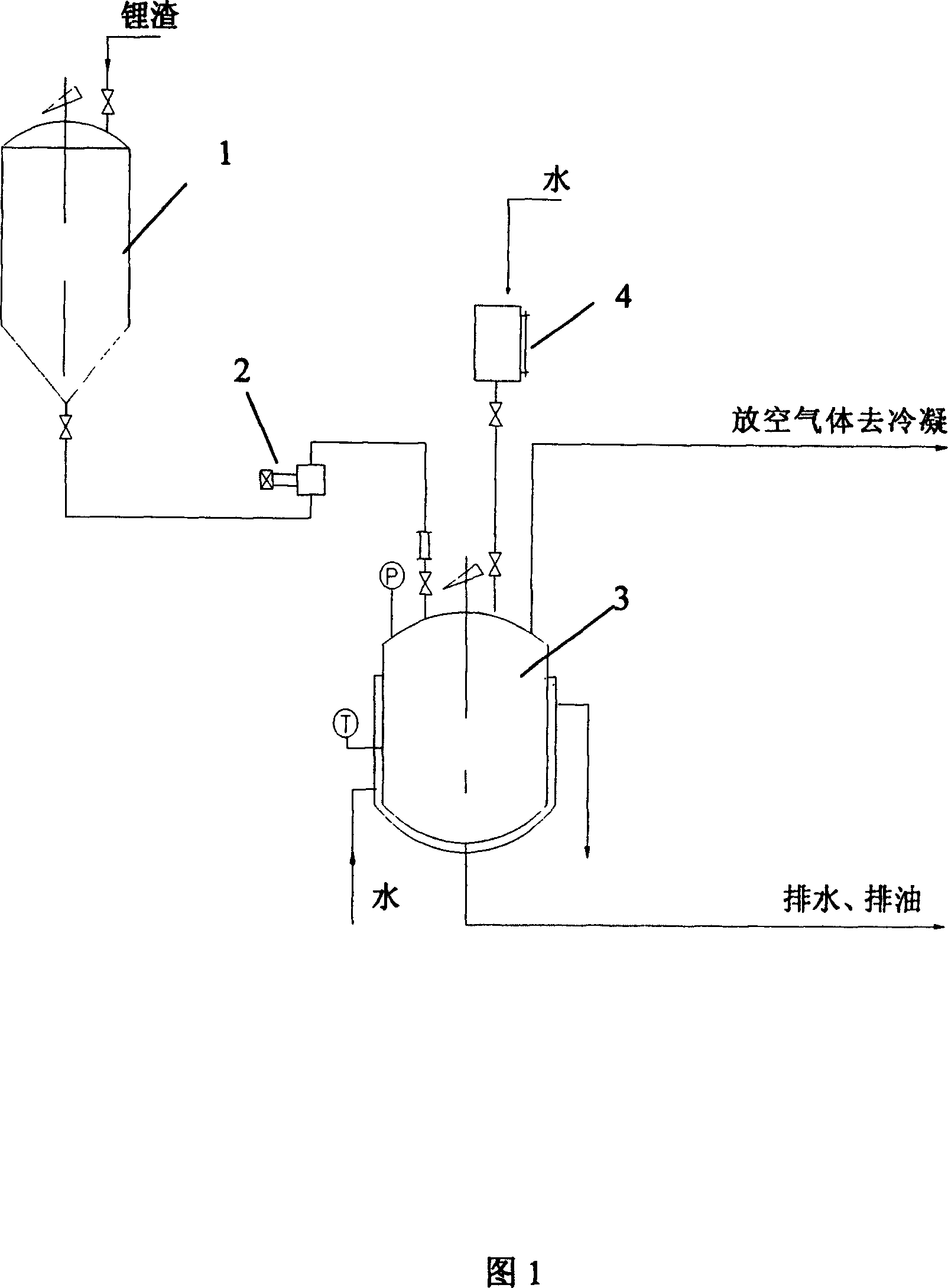

[0024] Slagging collection. Discharge about 500L of filtered lithium slag into a stirred lithium slag buffer tank at one time;

[0025] Add the measured 600L water into the hydrolysis kettle through the water metering tank, then use 0.3MPa nitrogen to maintain the pressure, replace it three times, and discharge the air in the hydrolysis kettle.

[0026] Check and open the venting process of the hydrolysis kettle, and open the jacket cooling water. Start the lithium slag buffer tank to stir, use the lithium slag metering pump to control the lithium slag flow rate at about 300L / h, control the reaction temperature ≤ 60°C, until all the lithium slag in the lithium slag buffer tank is added to the hydrolysis kettle, and the feeding process lasts for about 2 hours .

[0027] After the hydrolysis is completed, continue to stir for 1 to 2 hours, and let stand for 2 hours. After the oil and water are separated, the oil phase is recovered, and the water phase is sent to the lithium wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com