High-efficient stable polishing-grinding apparatus

A polishing and stable technology, applied in the direction of grinding drive devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problem that the small bevel gear cannot be designed to meet the strength requirements, there is no transmission system, and structural improvement , complex transmission system, etc., to achieve the effect of being conducive to popularization and application, reducing driving power and simple transmission form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail by the following examples.

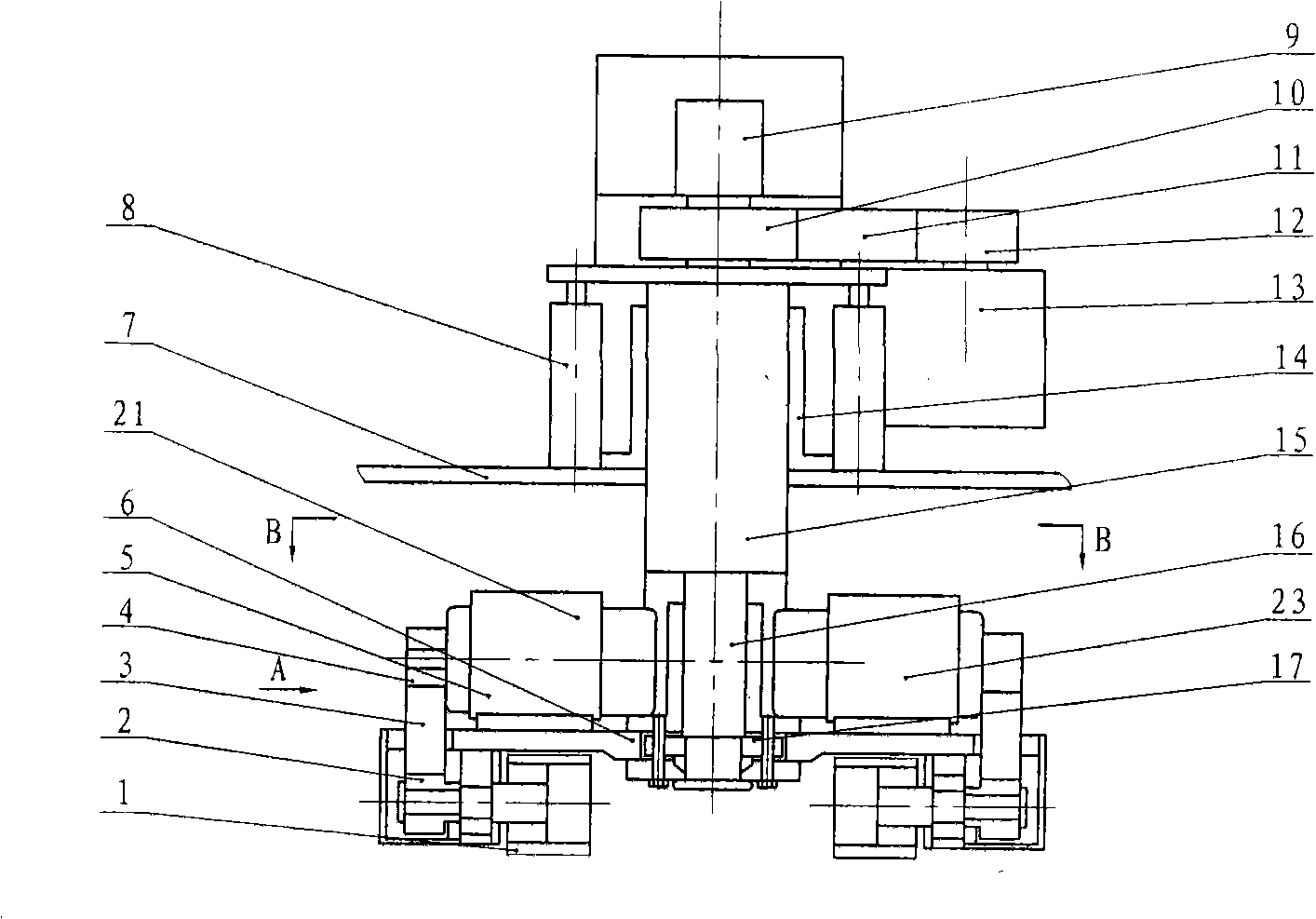

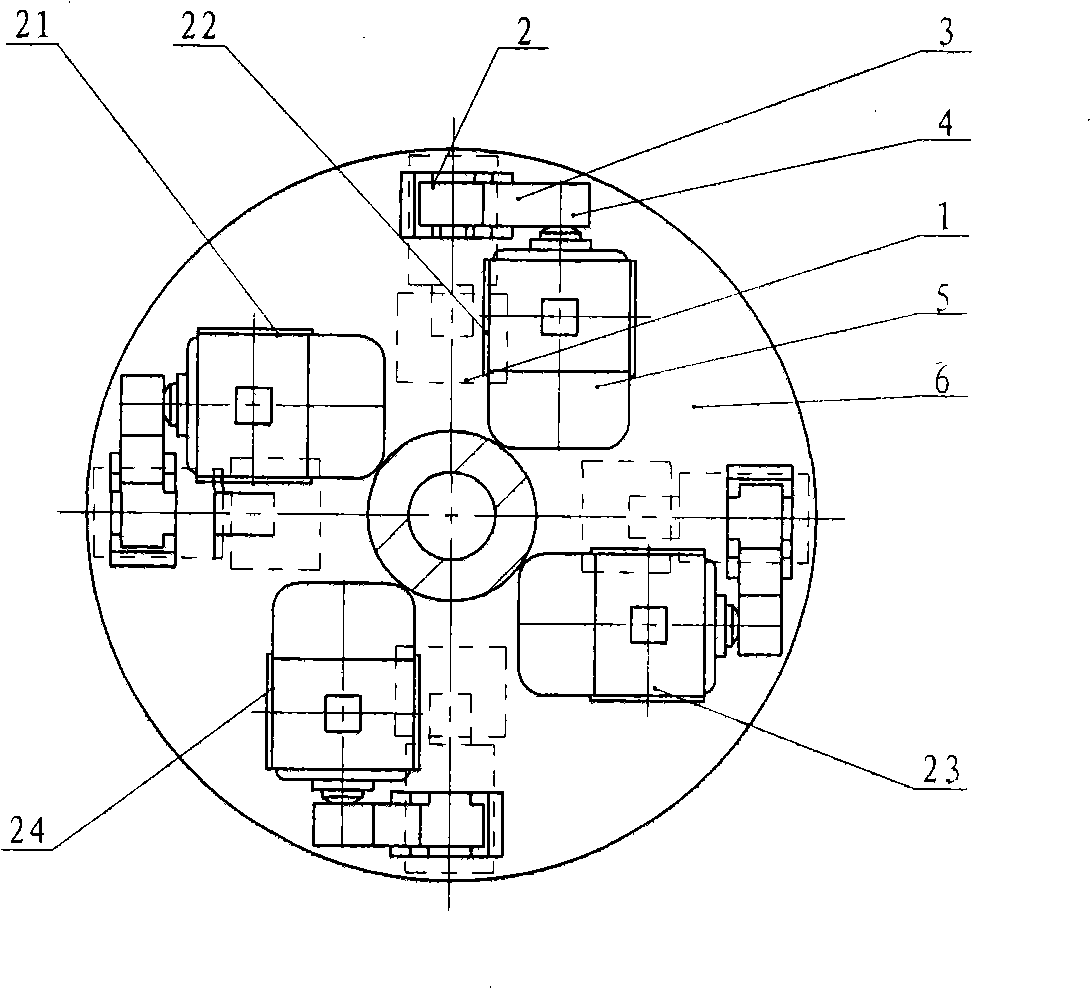

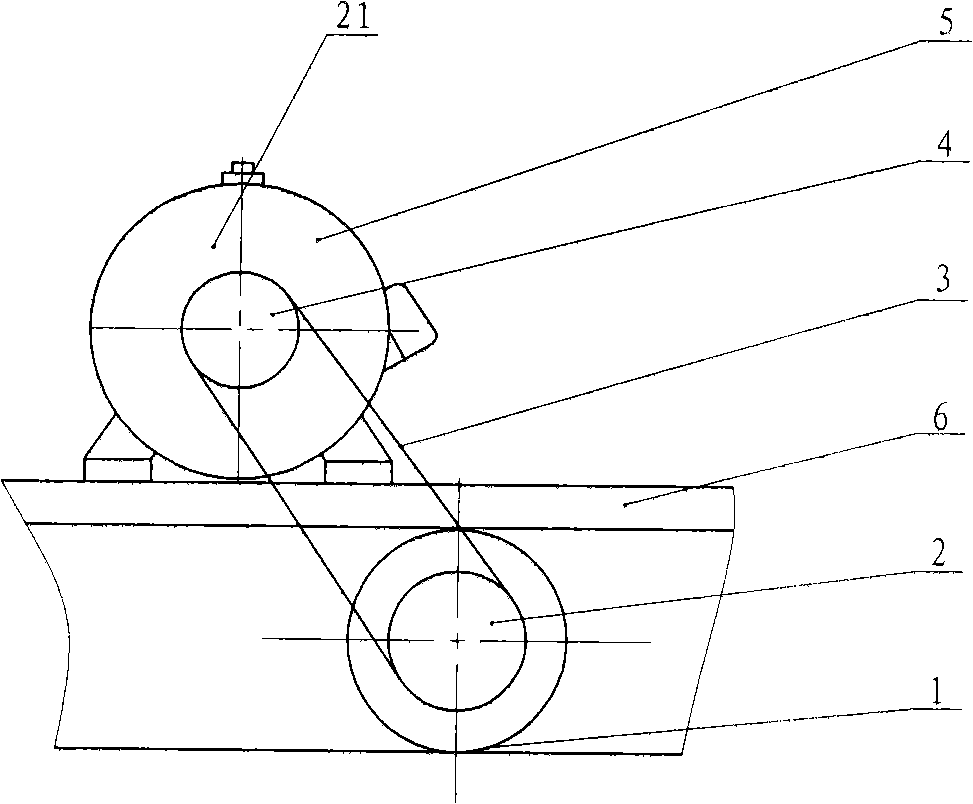

[0016] see figure 1 , figure 2 , image 3 , Figure 4 As shown, an efficient and stable polishing and grinding device is composed of a turntable revolution mechanism, a turntable lifting mechanism and multiple sets of high-speed self-rotating grinding mechanisms installed on the turntable. The turntable revolution mechanism consists of a turntable 6, a collector ring 9, and a turntable driving wheel. 12. Turntable belt 11, turntable driven wheel 10, turntable motor 13, main shaft 16 and main shaft damping connector 17. The turntable 6 is connected to the lower part of the main shaft 16 through the main shaft damping connector 17, and the turntable driven wheel 10 is installed on the main shaft 16. The upper part, the inner ring of the slip ring 9 is fixed on the top of the main shaft 16, and the external power supply is supplied to the four groups of high-speed self-rotating grinding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com