Positioning mechanism and disassembling-and-assembling method for achieving blade-assembly rapid disassembling and assembling and grass thinning machine

A positioning mechanism and component technology, applied in agricultural machinery and implements, harvesters, cutters, etc., can solve problems such as inconvenient operation, broken screw teeth, cumbersome problems, etc., and achieve the effect of convenient operation and avoiding the loss of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

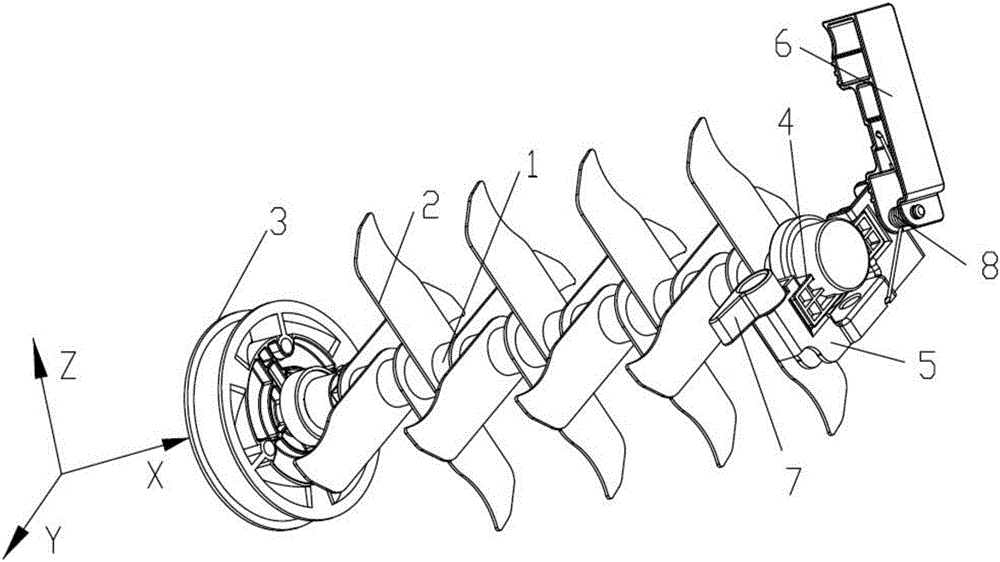

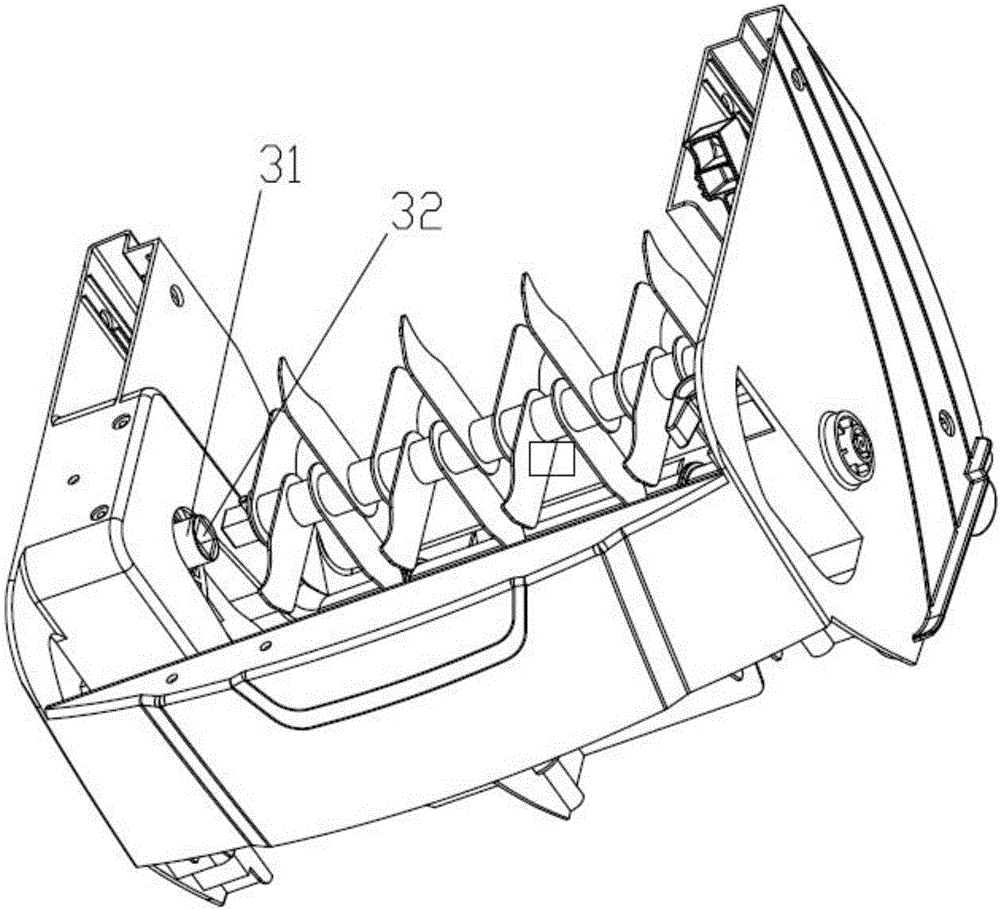

[0037] Please also see Figure 1 to Figure 5 , a positioning mechanism for realizing quick disassembly and assembly of the blade assembly. The positioning mechanism is used to respectively position the two ends of the blade assembly. The blade assembly includes a rotating shaft 1 and blades 2 evenly distributed on the rotating shaft 1. The positioning mechanism includes Transmission wheel 3, one end of the rotating shaft is inserted and fixed in the transmission wheel 3, and rotates synchronously with the transmission wheel.

[0038]There is a positioning part 31 protruding from the middle of the transmission wheel 3, and a positioning groove 32 is formed in the positioning part 31. The positioning groove 32 matches the end of the rotating shaft 1. One end of the rotating shaft 1 is inserted into the positioning groove 32 to limit the position and rotate synchronously with the driving wheel 3. , define the axial direction of the rotating shaft 1 as the X axis, the Y axis and t...

Embodiment 2

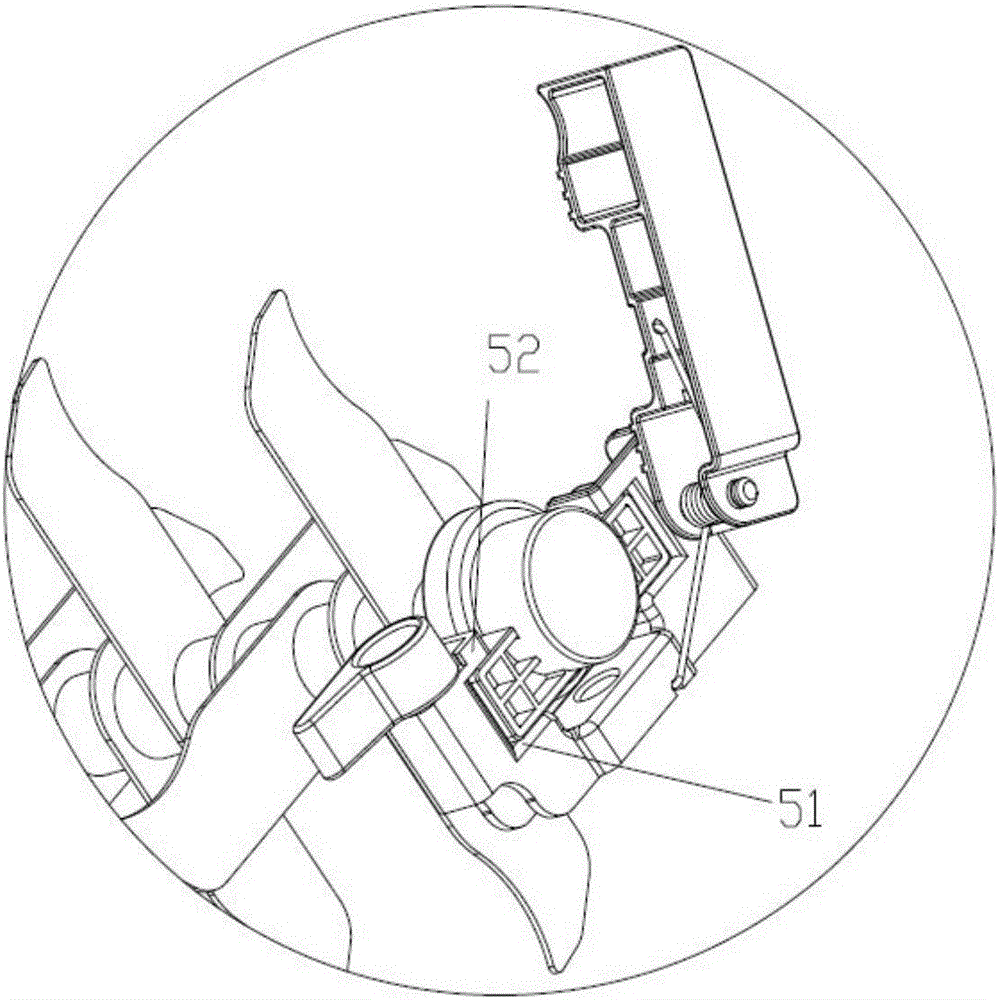

[0055] The rest are the same as in Embodiment 1, the difference is that the blade seat 5 is provided with a draw-in groove 51 for placing the bearing seat 4, the bottom of the bearing seat 4 matches the draw-in groove 51, and the bearing seat 4 extends along the axis from the blade seat 5 side. Locked into the slot 51 horizontally, the blade holder 5 limits the rotation of the rotating shaft in the direction of the Z axis. In this embodiment, the limiting part on the blade seat is omitted. In order to ensure the movement in the X-axis direction and the rotation limit in the Y-axis direction, the limiting block is designed as an L-shaped structure. After installation, the limiting block The upper side and the outer end of the blade seat limit the rotation of the rotating shaft in the Y-axis direction and the movement in the X-axis direction. The assembly and fixation of the blade assembly can also be realized.

[0056] The invention discloses a positioning mechanism for quick ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com