Suction cup type micro-arc oxidation clamp

A micro-arc oxidation, sucker-type technology, applied in anodizing, electrolytic process, electrolytic components, etc., can solve the problems of reducing the production efficiency of micro-arc oxidation, inaccurate calculation of total current, destroying workpieces, etc., and achieves simple structure and versatility. Strong and conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described.

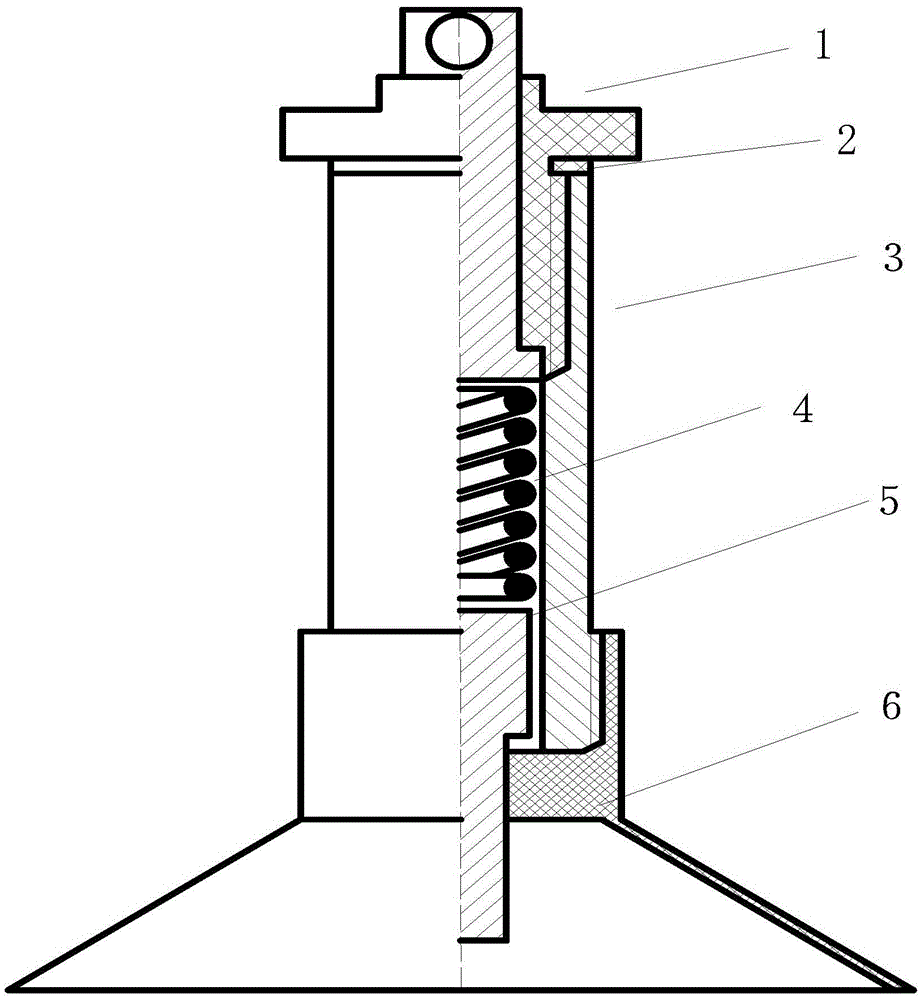

[0017] see figure 1 .

[0018] A sucker-type micro-arc oxidation fixture, which is composed of a conductive nut 1, a sealing gasket 2, a PVC pipe 3, a conductive spring 4, an electrode 5, and a suction cup 6. The two ends of the PVC pipe 3 are connected to the conductive nut 1 and the suction cup through threads respectively. 6 connected, there is a conductive spring 4 and an electrode 5 in the PVC pipe 3; the conductive nut 1 is located above the PVC pipe 3, and there is a sealing gasket 2 between the conductive nut and the PVC pipe, and the conductive nut is composed of a nut and a copper column , the copper column penetrates the center of the nut and is fixed, the copper column of the conductive nut 1 is above the conductive spring 4, and the T-shaped electrode 5 is below, the upper diameter of the electrode is the same as the outer diameter of the conductive spring, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com