Super-hydrophilic agent, preparation method of super-hydrophilic agent, and super-hydrophilic window glass

A hydrophilic agent and super-hydrophilic technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of increasing driving risk, increasing the temperature inside the car, and high light transmittance, achieving improved microscopic roughness and excellent electrical conductivity Performance, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a kind of preparation method of above-mentioned superhydrophilic agent simultaneously, it is characterized in that, comprises the steps:

[0041] Step 10: preparing zinc oxide nanorods;

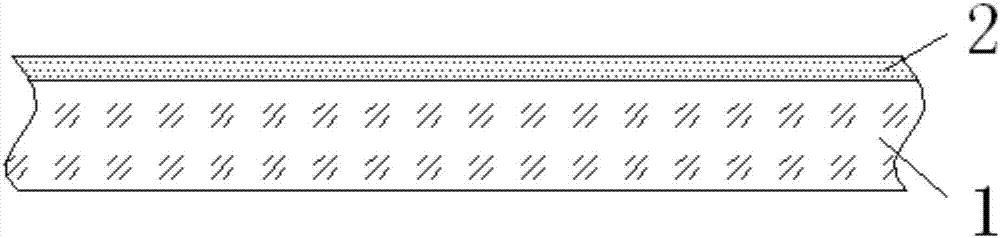

[0042] Step 20: dissolving 0.1-0.45wt% zinc oxide nanorods into 12-18wt% N,N-dimethylformamide to prepare zinc oxide sol;

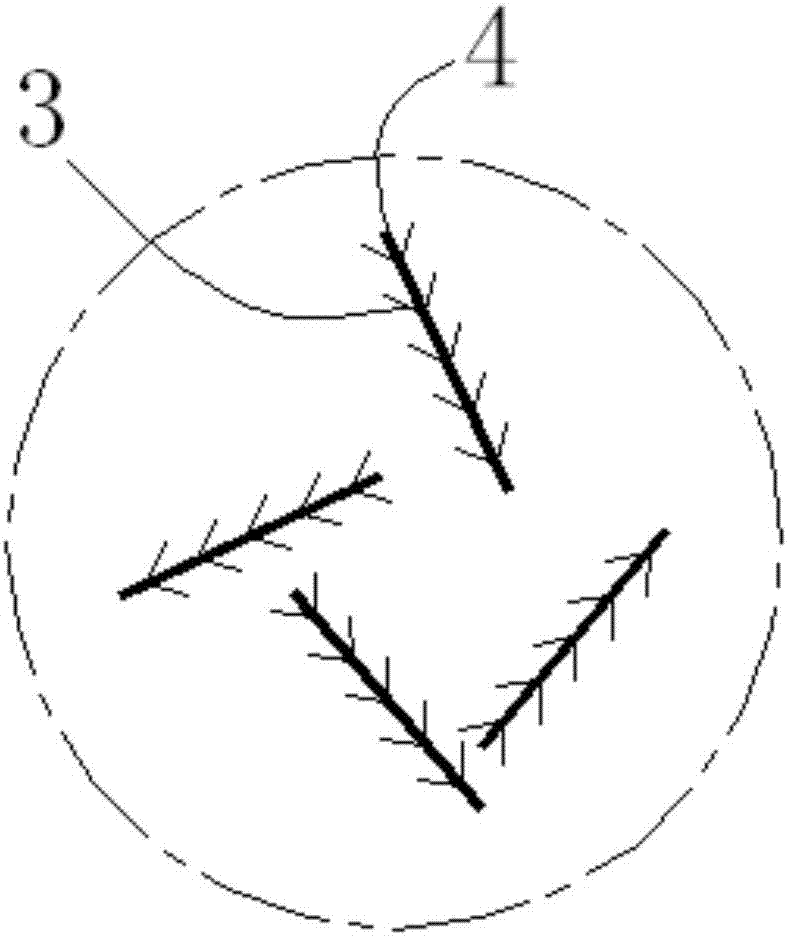

[0043] Step 30: Mix a dispersant with a volume ratio of 5-8:1 and a strong acid solution to form a dispersion, then add 1.5-5 wt% carbon nanotube powder to make the pH of the solution 2-4, and then Stir at 30°C for 1 to 3 hours, and mix evenly to obtain a carbon nanotube dispersion;

[0044] Step 40: Gradually add the carbon nanotube dispersion prepared in Step 30 to the zinc oxide sol prepared in Step 20 under continuous stirring, and then age for 10-24 hours to form a superhydrophilic agent. Wherein, wt% is weight percentage, h is hour, and the weight percentage of each component mentioned above refers to its weight ratio th...

Embodiment 1

[0056] Embodiment 1: the preparation method of superhydrophilic agent

[0057] (1) Preparation of nano-zinc oxide: 1g of zinc acetate dihydrate (Zn(OAc) 2 2H 2 O) and 0.1g triamine citrate ((NH 4 ) 3 C 6 h 5 o 7 ) into 120ml of absolute ethanol, condensed and refluxed at a temperature of 90°C and stirred continuously to dissolve it, and the prepared solution was cooled and stored in a refrigerator at a temperature of 3°C to obtain a precursor solution; 0.1g of sodium hydroxide (NaOH) was added to 30ml of absolute ethanol, ultrasonically dissolved at room temperature for a period of 40min (minutes), and then the prepared 20ml of sodium hydroxide ethanol solution was added to the prepared 60ml of the precursor solution, in a water bath with a temperature of 70°C Continue to react in the environment for a period of 4 hours (hours), after ultrasonication, centrifugation, and washing for 3 to 5 times, dry at room temperature to prepare zinc oxide nanorods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com