Electronic expansion valve

A technology of electronic expansion valve and valve body, which is applied in the direction of valve details, valve device, valve operation/release device, etc. It can solve the problems that grounding cannot be realized, grounding cannot be guaranteed, and the contact of magnetic conductor cannot be absolutely guaranteed, so as to avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

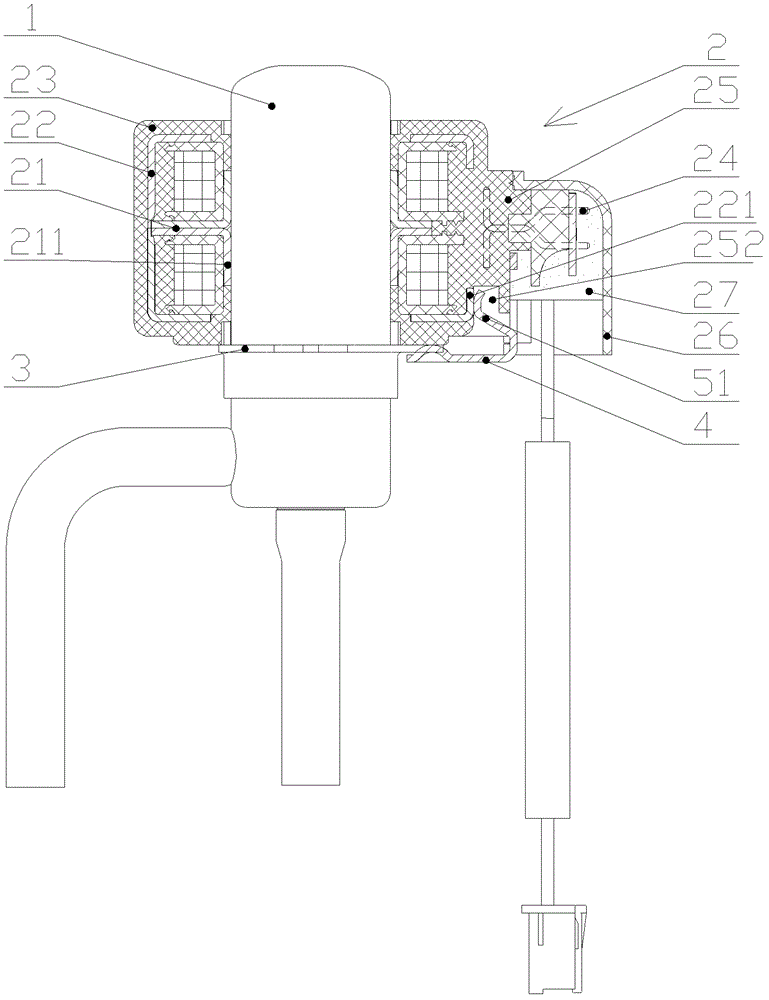

[0039] The core of the present invention is to provide an electronic expansion valve, the structural design of which can ensure the grounding of parts inside the coil, so as to avoid damage to the coil caused by high-voltage or ultra-high-voltage electrical signals.

[0040] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

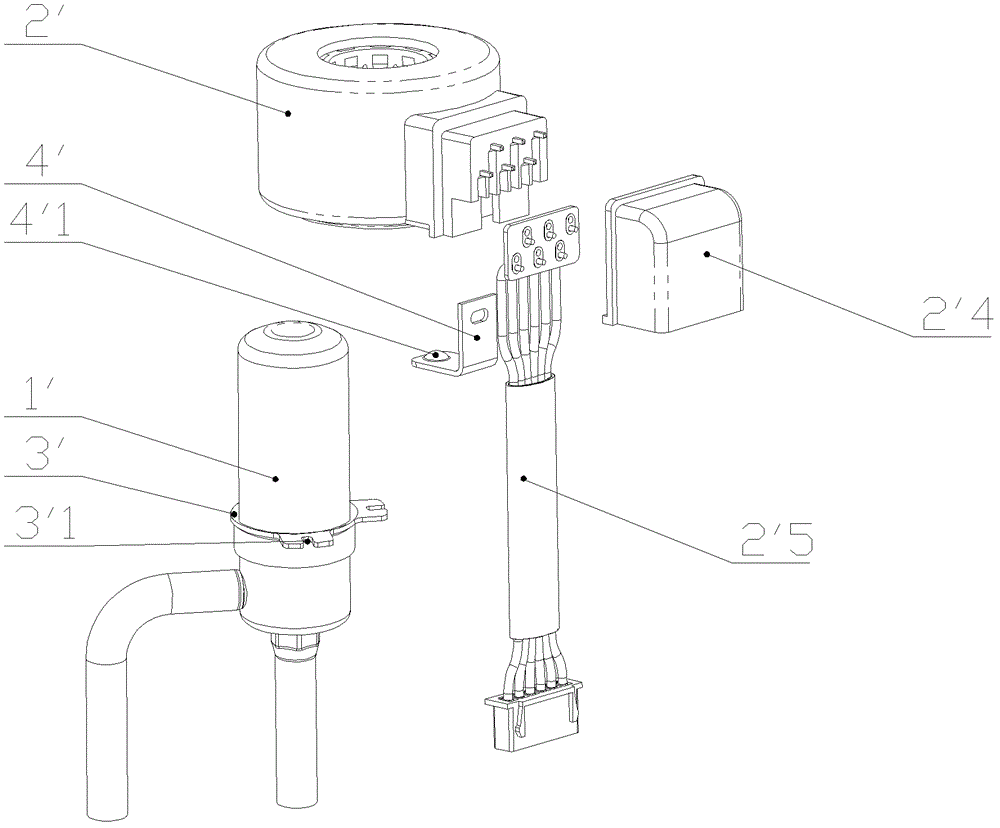

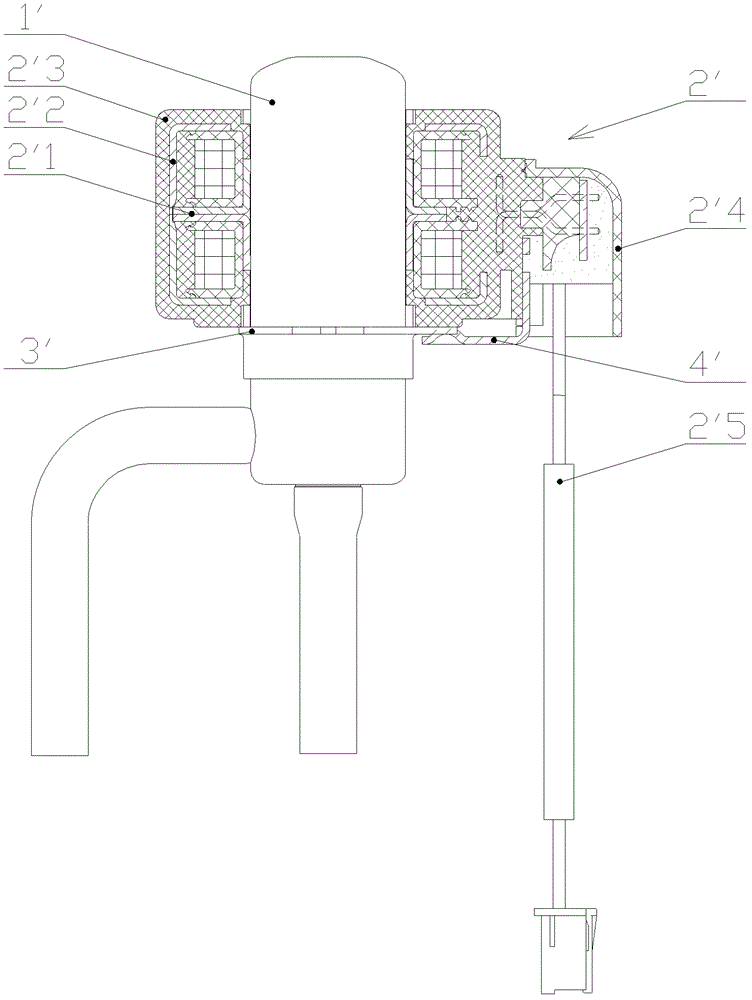

[0041] Please refer to image 3 , Figure 3-1 with Figure 3-2 , image 3 It is a schematic structural diagram of the electronic expansion valve in the first embodiment of the present invention; Figure 3-1 for image 3 Processing and assembly flow chart of the coil of the electronic expansion valve; Figure 3-2 for image 3 Processing flow chart of the buckle and transition part of the middle coil.

[0042] In the basic technical scheme of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com