Conductive anticorrosion coating and preparation method thereof

A conductive anti-corrosion and coating technology, applied in anti-corrosion coatings, conductive coatings, fire-resistant coatings, etc., can solve the problems of insufficient electrical conductivity, poor corrosion resistance, serious metal pollution, etc., to improve construction technology and stable electrical conductivity. , good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

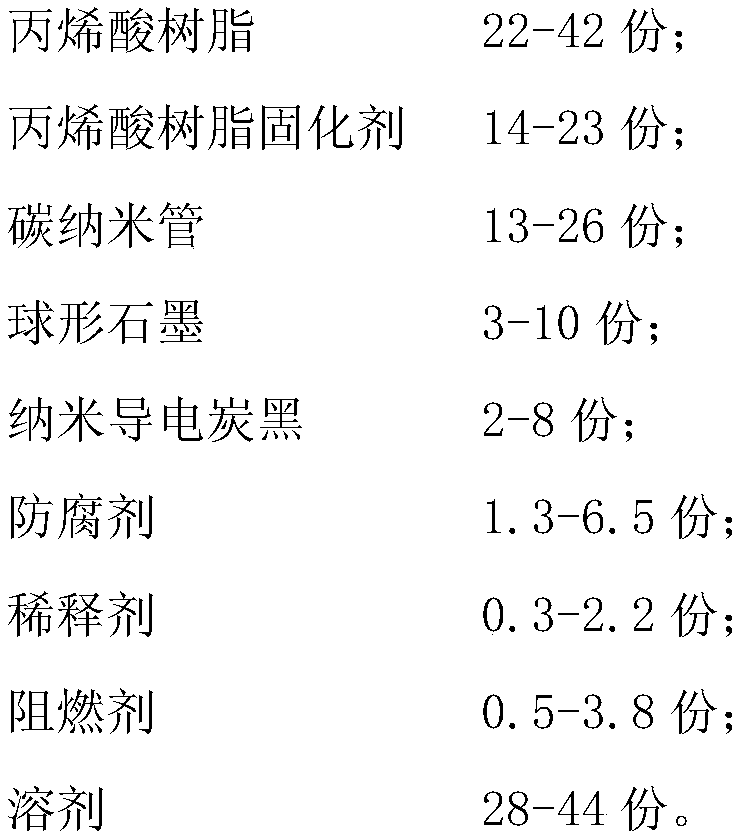

[0031] A conductive anticorrosion coating, in parts by weight, the coating mainly includes the following components:

[0032]

[0033]

[0034] Wherein, the acrylic resin is selected from 4365A.

[0035] Wherein, the weight ratio of the preservative is a mixture of magnesium tripolyphosphate and polyferric phosphorus powder in a weight ratio of 1:4.

[0036] Wherein, the diluent is selected from benzyl glycidyl ether.

[0037] Wherein, the flame retardant is calcium polyphosphate.

[0038] Wherein, the solvent is a mixture of n-butanol and acetone with a mass ratio of 0.5:1.

[0039] The present invention also provides a preparation method for conductive anticorrosion paint, comprising the following steps:

[0040] (1) Pre-mixing: Add solvent, diluent, preservative, flame retardant and acrylic resin into the dispersing tank, fully stir and mix to form a gel-like mixture, and control the mixing speed at 500rpm;

[0041] (2) Grinding and dispersing: add carbon nanotube...

Embodiment 2

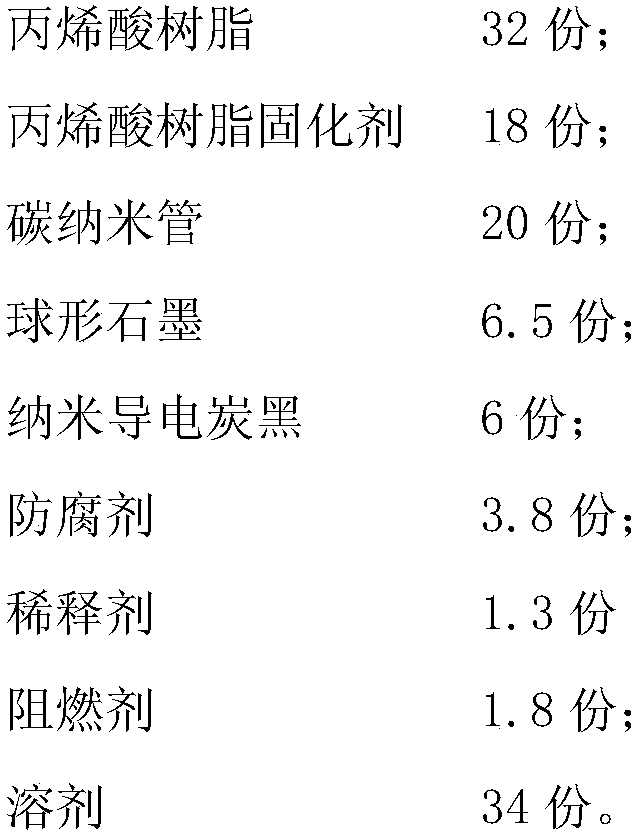

[0045] A conductive anticorrosion coating, in parts by weight, the coating mainly includes the following components:

[0046]

[0047] Wherein, the acrylic resin is selected from 2060A.

[0048] Wherein, the weight ratio of the preservative is a mixture of magnesium tripolyphosphate and polyferric phosphorus powder in a weight ratio of 1:2.

[0049] Wherein, the diluent is selected from benzyl glycidyl ether and butyl glycidyl ether.

[0050] Wherein, the flame retardant is calcium polyphosphate and diphenyl phosphate.

[0051] Wherein, the solvent is a mixture of n-butanol and acetone with a mass ratio of 0.3:1.

[0052] The present invention also provides a preparation method for conductive anticorrosion paint, comprising the following steps:

[0053] (1) Pre-mixing: Add solvent, diluent, preservative, flame retardant and acrylic resin into the dispersing tank, fully stir and mix to form a gel-like mixture, and control the mixing speed at 400rpm;

[0054] (2) Grinding...

Embodiment 3

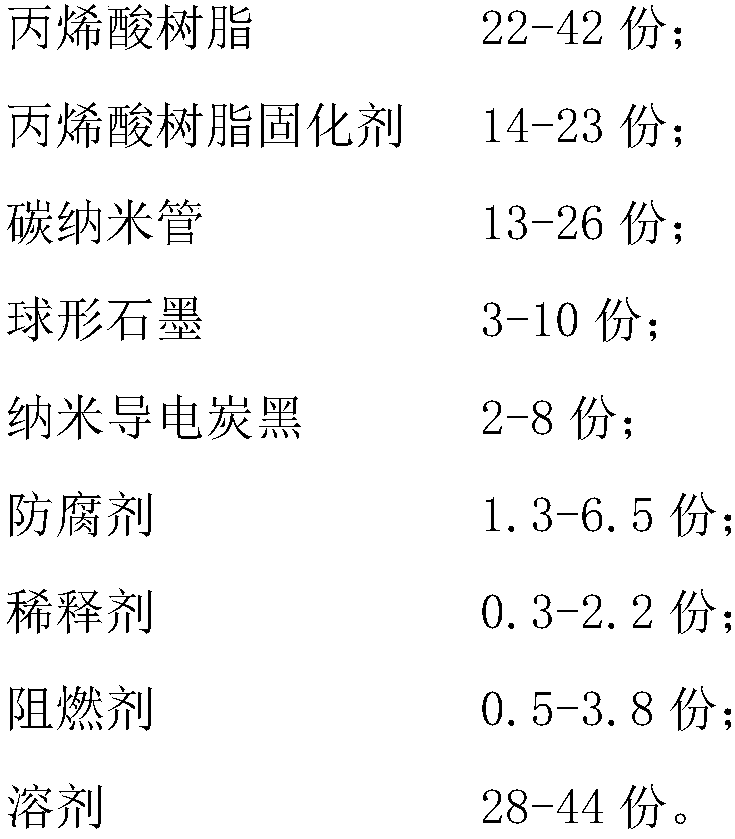

[0058] A conductive anticorrosion coating, in parts by weight, the coating mainly includes the following components:

[0059]

[0060] Wherein, the acrylic resin is selected from 4365A.

[0061] Wherein, the weight ratio of the preservative is a mixture of magnesium tripolyphosphate and polymerized ferrophosphorus powder in a weight ratio of 1:6.

[0062] Wherein, the diluent is selected from benzyl glycidyl ether and butyl acetate.

[0063] Wherein, the flame retardant is diphenyl phosphate.

[0064] Wherein, the solvent is a mixture of n-butanol and acetone with a mass ratio of 0.8:1.

[0065] The present invention also provides a preparation method for conductive anticorrosion paint, comprising the following steps:

[0066] (1) Pre-mixing: Add solvent, diluent, preservative, flame retardant and acrylic resin into the dispersing tank, fully stir and mix to form a gel-like mixture, and control the speed of mixing and stirring at 600rpm;

[0067] (2) Grinding and dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com