Modular high-definition LED (light emitting diode) daylight lamp

A technology of LED fluorescent lamp and LED light source, applied in the direction of light source, electric light source, point light source, etc., can solve the problems of unstable work, high failure rate, difficult maintenance, etc., and achieve the effect of simple structure, low cost, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

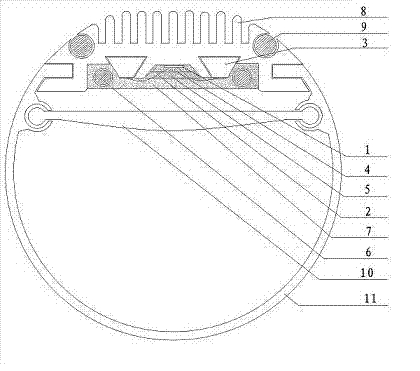

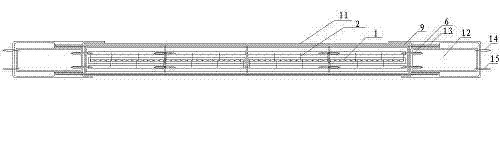

[0020] Such as figure 1 , 2 As shown, this modular high-definition LED fluorescent lamp is composed of blue LED chip 1, metal wire 2, circuit board 3, transparent silicone layer 4, phosphor layer 5, connector 6, transparent epoxy resin 7, radiator 8, connecting Part 9, secondary light distribution mirror 10, housing 11, constant current power supply module 12, constant current power supply housing 13, external power supply terminals 14, 15. Firstly, a plurality of blue LED chips 1 are implanted into the reflective cup of the heat sink 8 by using a high-precision solid crystal machine, and then through a fully automatic wire bonding machine, the metal wire 2 (gold wire is used in this embodiment) and the circuit board 3 ( In this embodiment, a PC circuit board) is electrically connected to the LED chip to complete the first process of solid crystal and wire bonding. Use a high-precision dispensing machine to put the transparent silica gel 4 into the reflective cup of the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com