Rolling mill

A rolling mill and roll technology, applied in the field of rolling mills, can solve problems such as poor stability, poor rolling precision, and low operating efficiency, and achieve the effects of improving strength and rigidity, convenient and quick operation, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

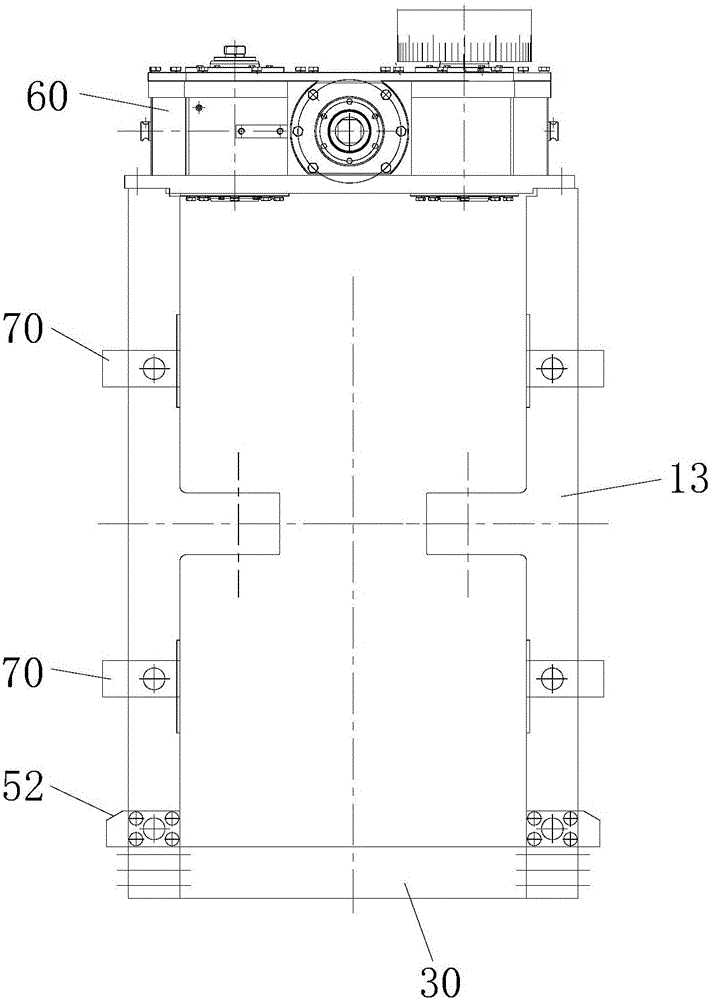

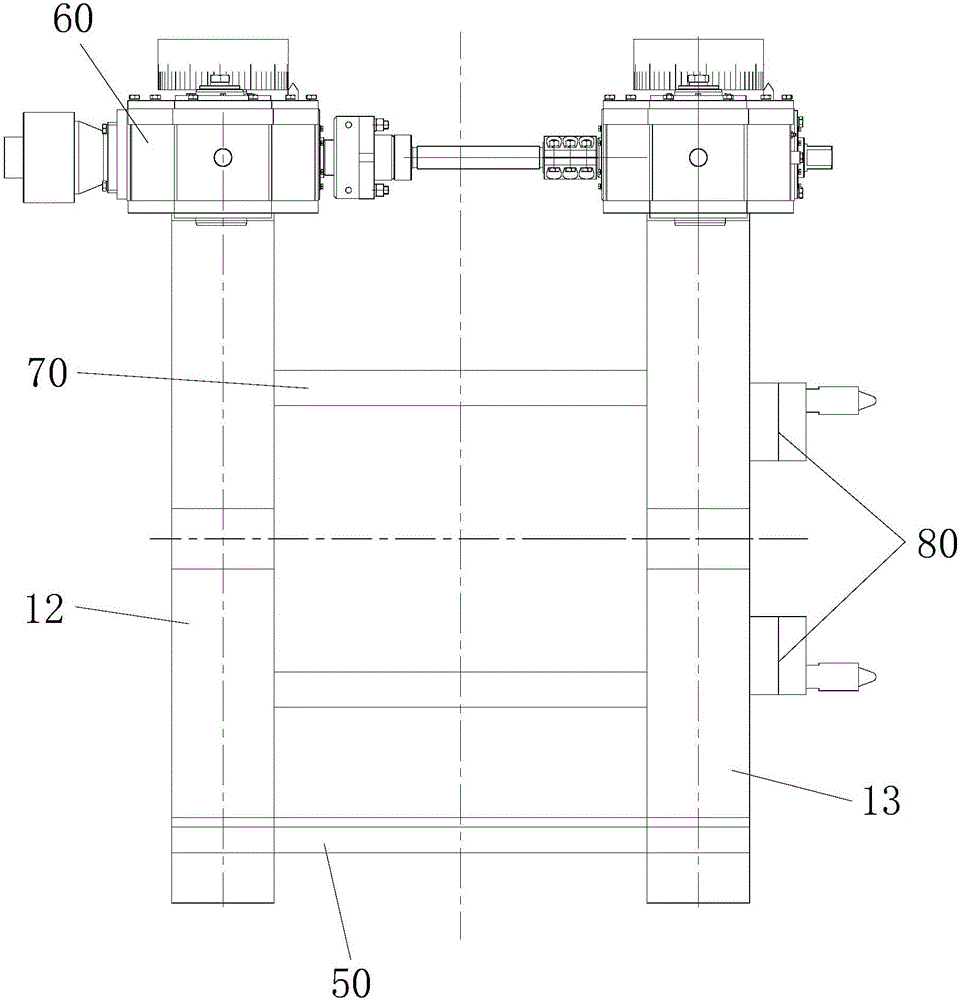

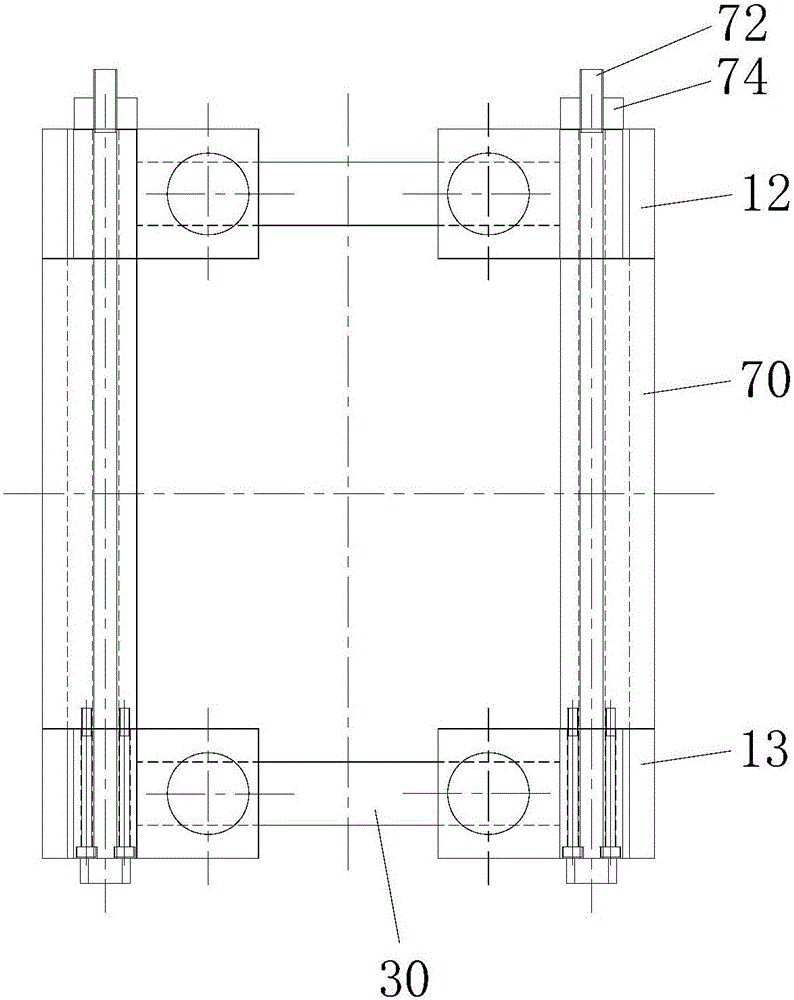

[0054] see figure 1 , figure 2 and image 3 As shown, a rolling mill includes a stand, a roll mechanism 20 and a pressing mechanism. The frame includes a left archway 12 and a right archway 13 arranged in parallel, and at least a pair of guide beams 70 horizontally connected between the left archway 12 and the right archway 13 . see Figure 4 , Figure 5 and Figure 6 As shown, the left archway 12 and the right archway 13 all include two opposite and vertically arranged columns 14 and a horizontally arranged connecting beam 30, and the two ends of the connecting beam 30 are detachably connected to the bottoms of the two columns 14 respectively; The guide crossbeams 70 are symmetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com