High-temperature superconducting magnet liquid nitrogen zero-evaporation cooling system

A high-temperature superconducting and cooling system technology, applied to superconducting magnets/coils, magnetic objects, electrical components, etc. The magnetic conductor is convenient, the operation procedure is simplified, and the cooling effect is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

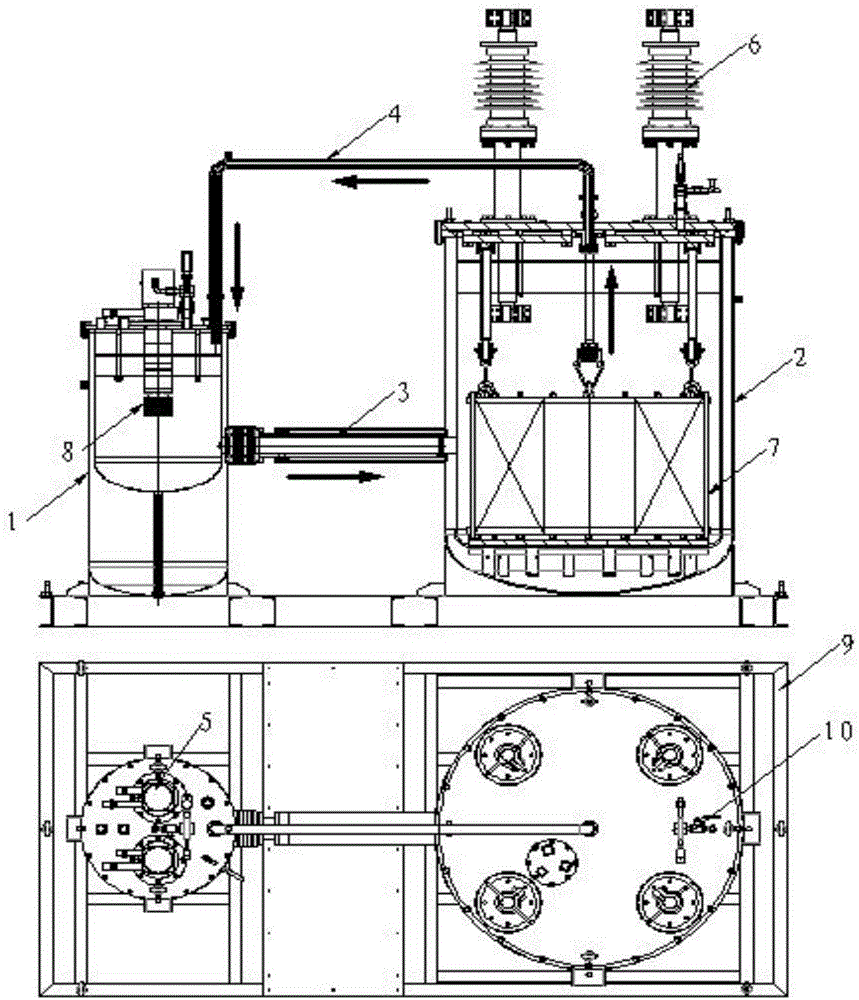

[0017] like figure 1 As shown, the high-temperature superconducting magnet liquid nitrogen zero-evaporation cooling system, the present invention includes a refrigerator installation Dewar 1, a magnet cooling Dewar 2, a liquid nitrogen communication pipeline 3, an evaporating nitrogen gas communication pipeline 4, an AL600G-M refrigerator 5, and a 1000V , 1000A current lead wire 6, high temperature superconducting magnet 7, cold head heat exchanger 8, integrated installation platform 9, safety component 10; among them: AL600G-M refrigerator 5 is installed on the upper cover flange of the refrigerator installation Dewar 1 Above, the high temperature superconducting magnet 7 is hoisted under the flange of the upper cover plate of the magnet cooling Dewar 2, and the 1000V, 1000A current lead wire 6 is installed on the upper cover plate of the magnet cooling Dewar 2; the refrigerator is installed with the Dewar 1 and the magnet cooling The Dewar 2 and the integrated installation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com