Surface-regulatory flexible microgroove heat sink, heat dissipation device and method

A heat dissipation method and heat dissipation device technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment construction parts, etc., can solve the problem of poor hydrophilicity on the surface of high molecular polymers, affecting the heat dissipation capacity of radiators, and affecting Microchannel capillary wetting height and liquid reflux capacity, etc., to achieve the effect of enhancing capillary wetting height and reflux capacity, increasing hydrophilicity, and improving capillary force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

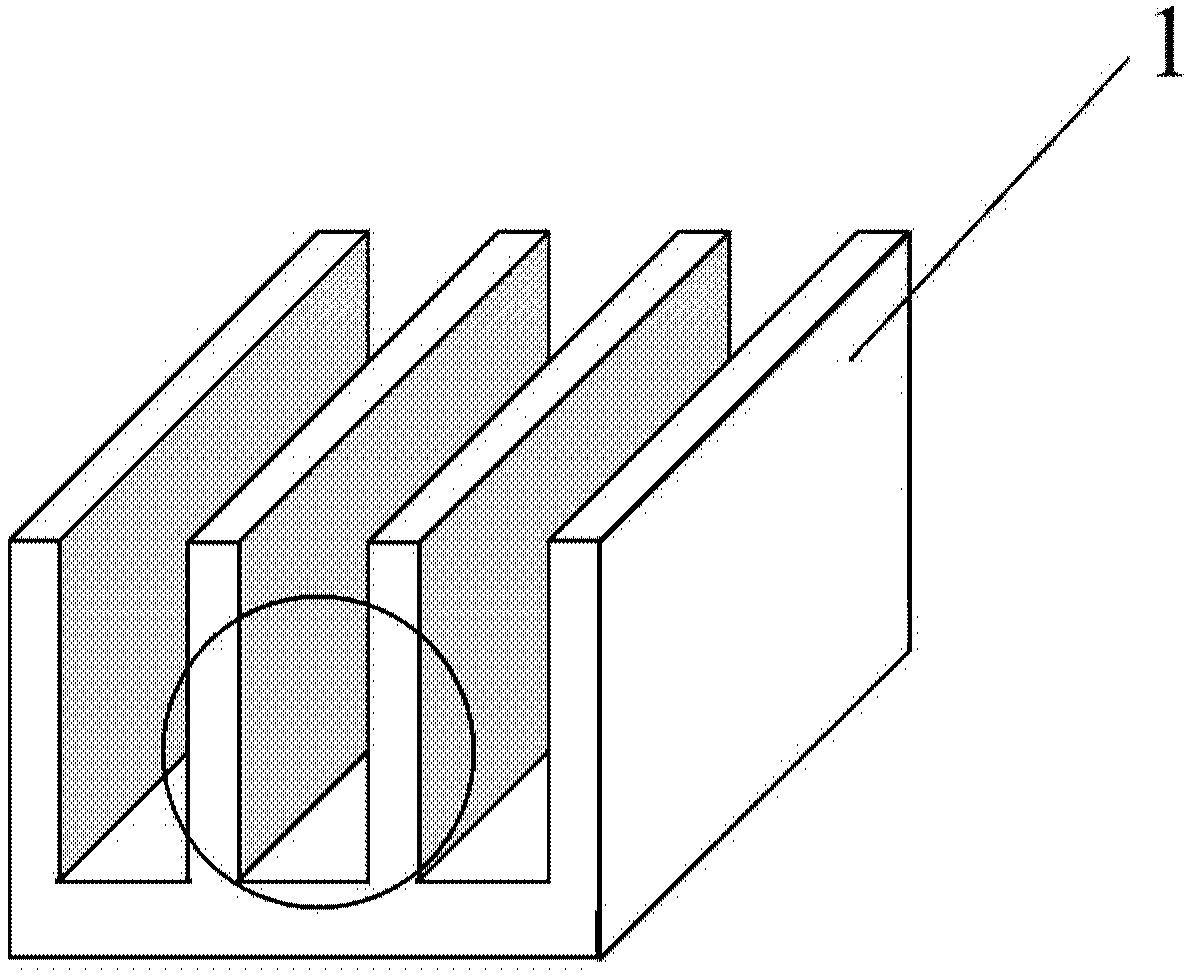

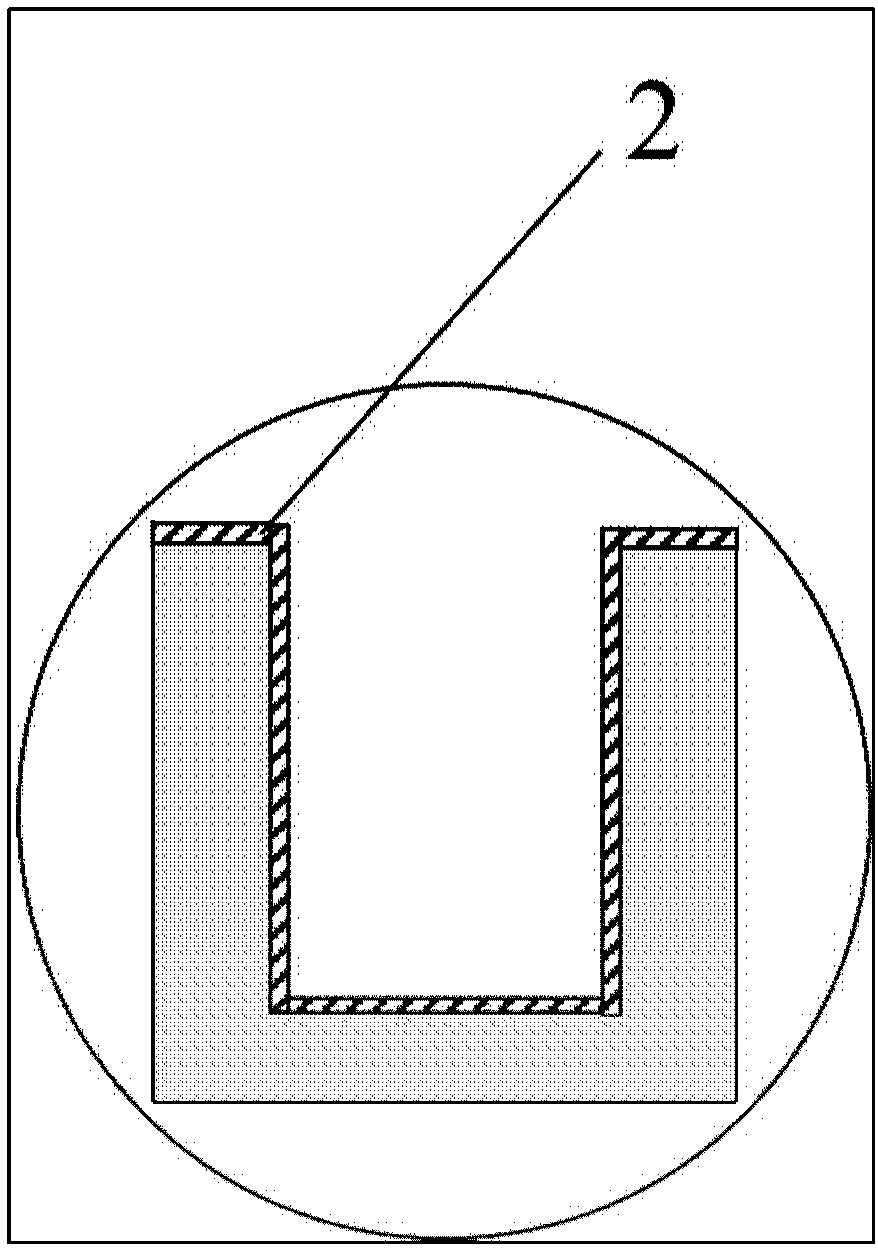

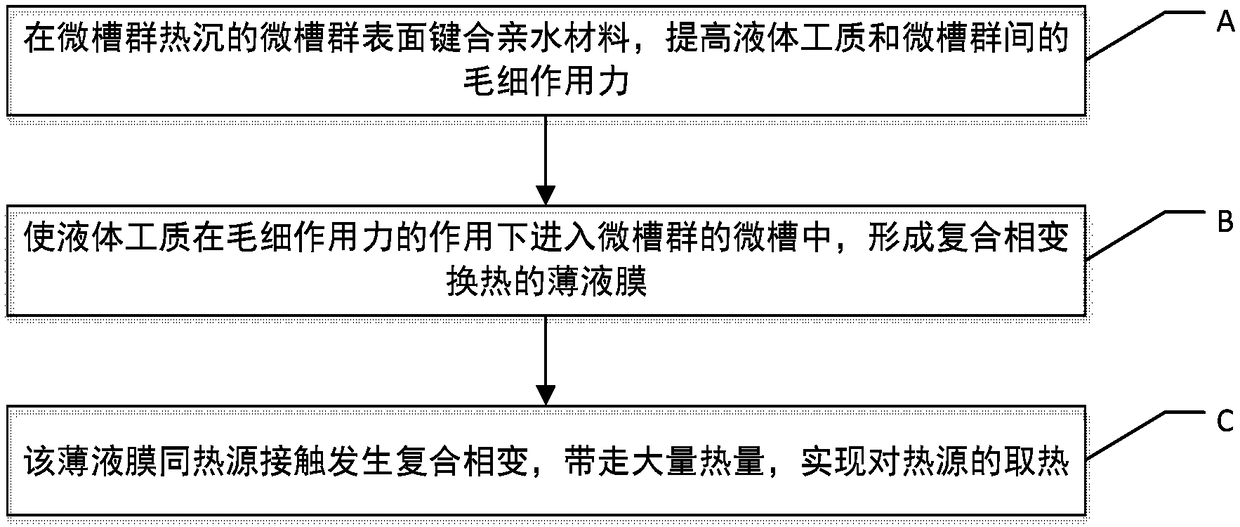

[0045] The present disclosure provides a flexible micro-groove group heat sink, heat dissipation device and method for surface control, by bonding hydrophilic materials on the surface of the micro-groove group of the flexible micro-groove group heat sink, the hydrophilic performance of the surface of the micro-groove group is improved, Increase the capillary force between it and the liquid working medium such as water, methanol, ethanol and other polar liquids, increase the wetting height and reflux capacity of the liquid working medium, and achieve the purpose of strengthening heat exchange.

[0046] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0047] As an exemplary embodiment of the present disclosure, a surface regulated flexible microgroove group heat sink, heat di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com