Liquid return preventing chimney

A chimney and anti-return technology, applied in the direction of smoke removal, combustion method, cleaning method and utensils, etc., to achieve the effect of convenient transportation, convenient transportation, convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

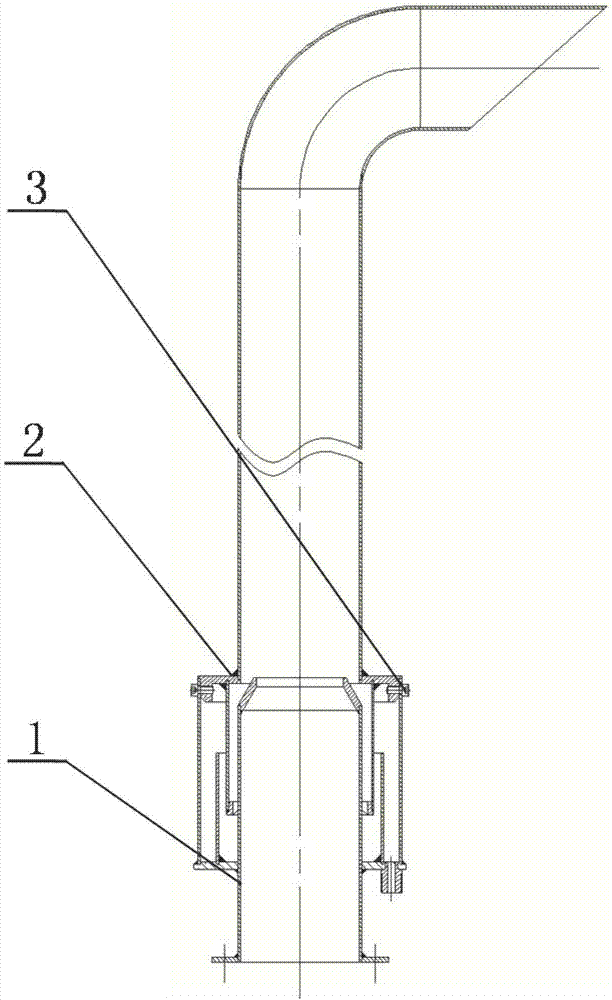

[0019] Such as figure 1 As shown, it includes a fixed part 1 of the chimney, a detachable part 2 of the chimney and a fastener 3, and the detachable part 2 of the chimney is fixed on the upper part of the fixed part 1 of the chimney through the fastener 3. When the equipment needs to be used or moved, the detachable part 2 of the chimney is directly connected or removed, and the fastener 3 is installed on the fixed part 1 of the chimney, which is convenient for transportation.

Embodiment 2

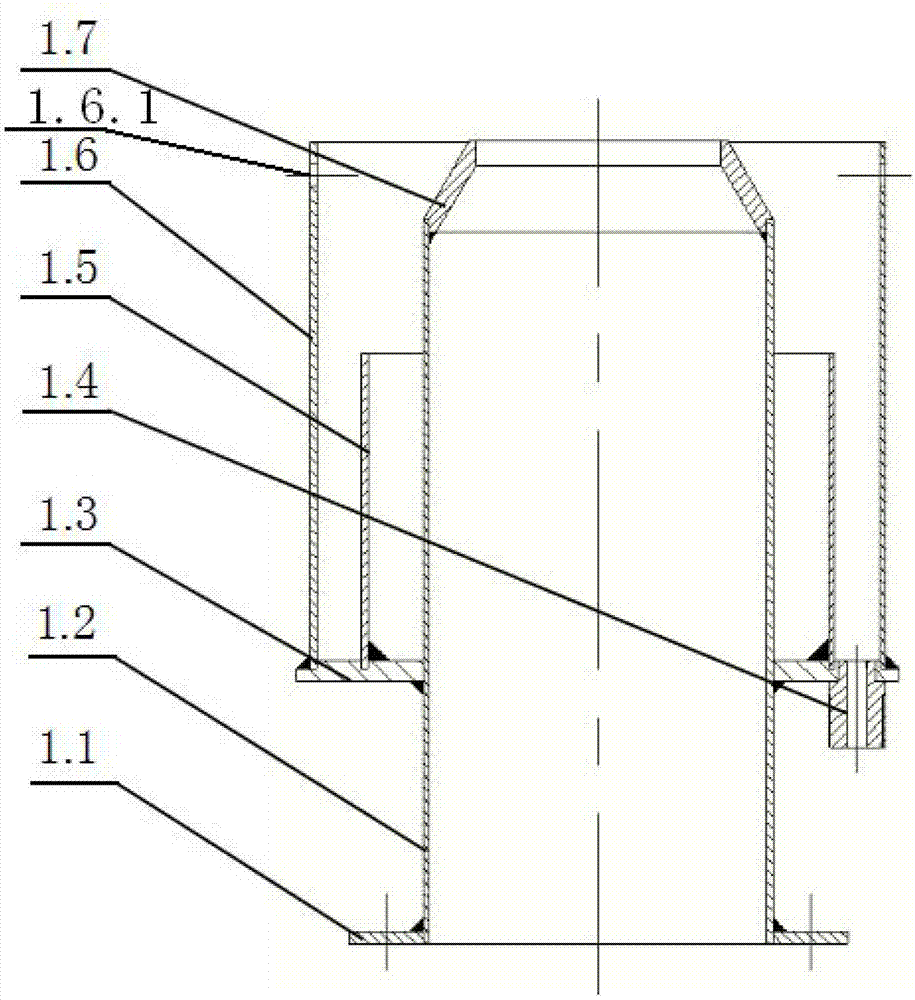

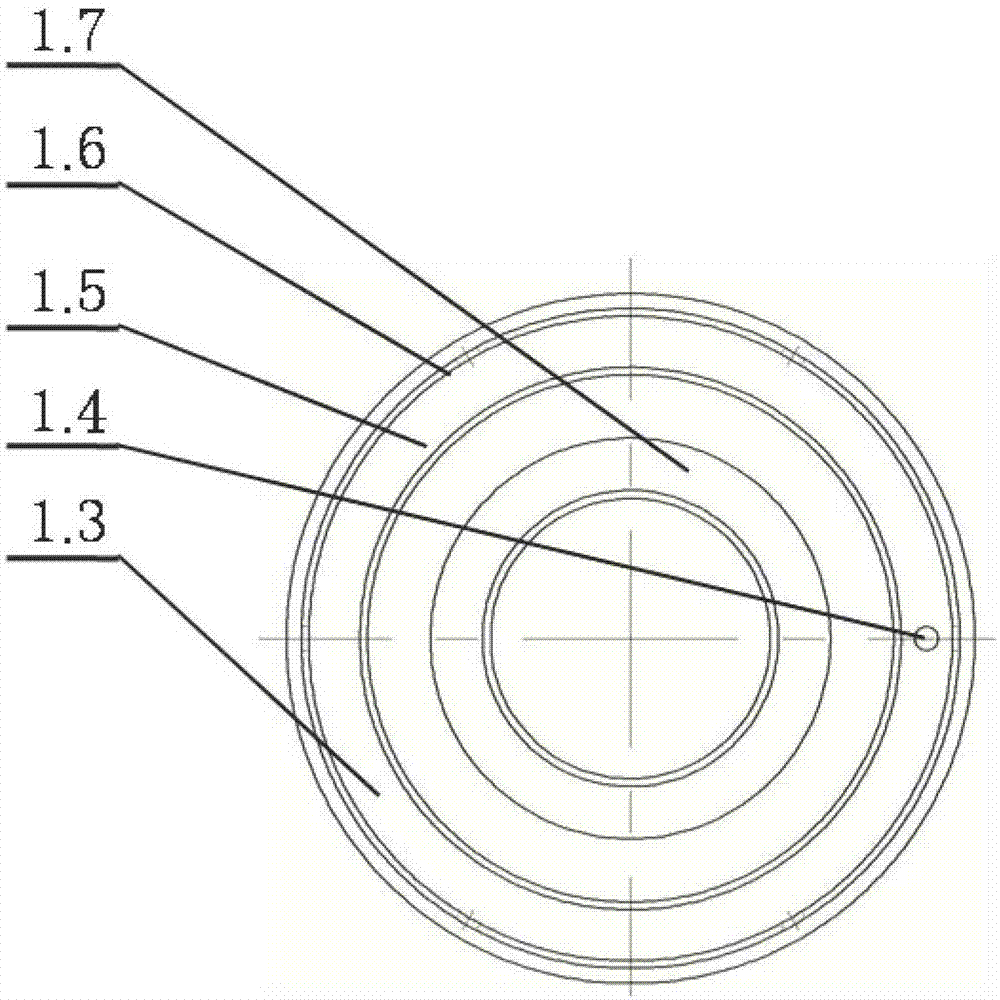

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, on the basis of Example 1, the chimney fixed part 1 includes a flange 1.1, a draft pipe 1.2, a bottom plate 1.3, a liquid discharge port 1.4, a liquid sealing shell 1.5, an outer shell 1.6 and a draft nozzle 1.7, the The top and bottom of the above-mentioned diversion pipe 1.2 are respectively connected to the diversion nozzle 1.7 and the flange 1.1, the bottom plate 1.3 is sleeved on the outside of the middle part of the diversion pipe 1.2, and the liquid seal shell 1.5 and the outer shell 1.6 are vertically sleeved on the diversion pipe from inside to outside. The outer side and the bottom of the tube 1.2 are connected to the upper part of the base plate 1.3, and the drain port 1.4 is connected to the lower part of the base plate 1.3 and is located between the liquid seal shell 1.5 and the outer shell 1.6, and the upper part of the outer shell 1.6 has a light hole 1.6.1. The detachable pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com