Reflux type ozone MBR (membrane bioreactor) sewage treatment equipment

A kind of sewage treatment equipment and ozone technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of reducing treatment time, high cost of membrane replacement, and short service life and other issues, to achieve the effect of prolonging the decay time, reducing the occupied area, and preventing biological pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

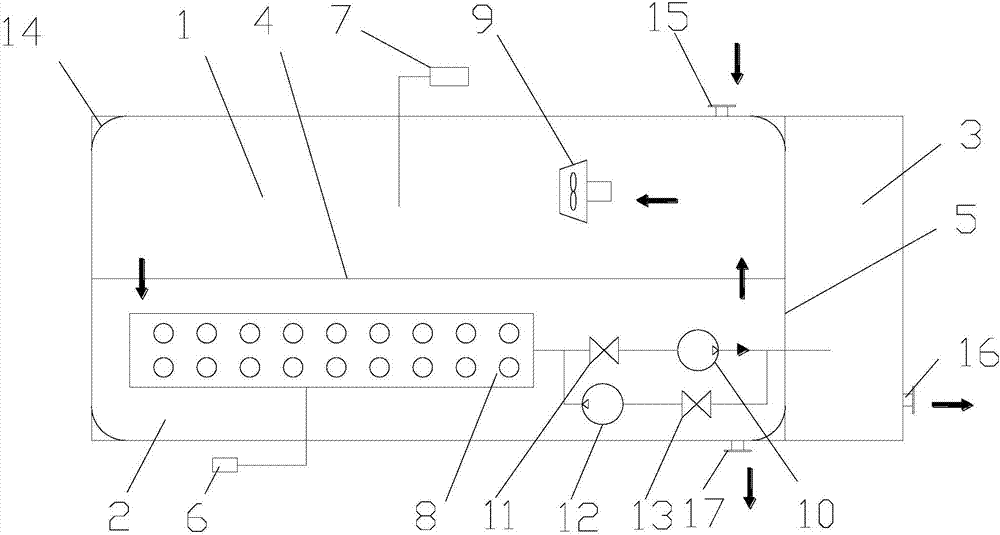

[0025] Such as figure 1 As shown, a kind of reflux type ozone MBR sewage treatment equipment provided by the present invention comprises reaction tank, MBR membrane group 8, ozone generator 6, aeration device, suction pump 10 and pusher 9; Described reaction tank is rectangular structure, in the reaction tank, a longitudinal partition 5 is provided, and the reaction tank is divided into a clear water tank 3 and a biochemical ozone reaction tank by the longitudinal partition 5; a transverse partition perpendicular to the longitudinal partition 5 is provided in the biochemical ozone reaction 4. The horizontal partition 4 divides the biochemical ozone reaction tank into a biochemical reaction tank 1 and an ozone reaction tank 2; the two ends of the horizontal partition 4 are respectively provided with a first flow hole and a second flow hole; Said pusher 9 is arranged at the bottom of the biochemical reaction tank, and promotes the sewage in the biochemical reaction tank 1 to flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com