Tin alloy plating solution

A technology of tin alloy and plating solution, which is applied in the direction of semiconductor devices, circuits, etc., can solve the problems of the appearance of the coating film and the uniformity of the film thickness, the problems of easy decomposition and precipitation of silver, etc., and achieve good appearance and uniformity of the film thickness Excellent stability, excellent bendability and reflowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

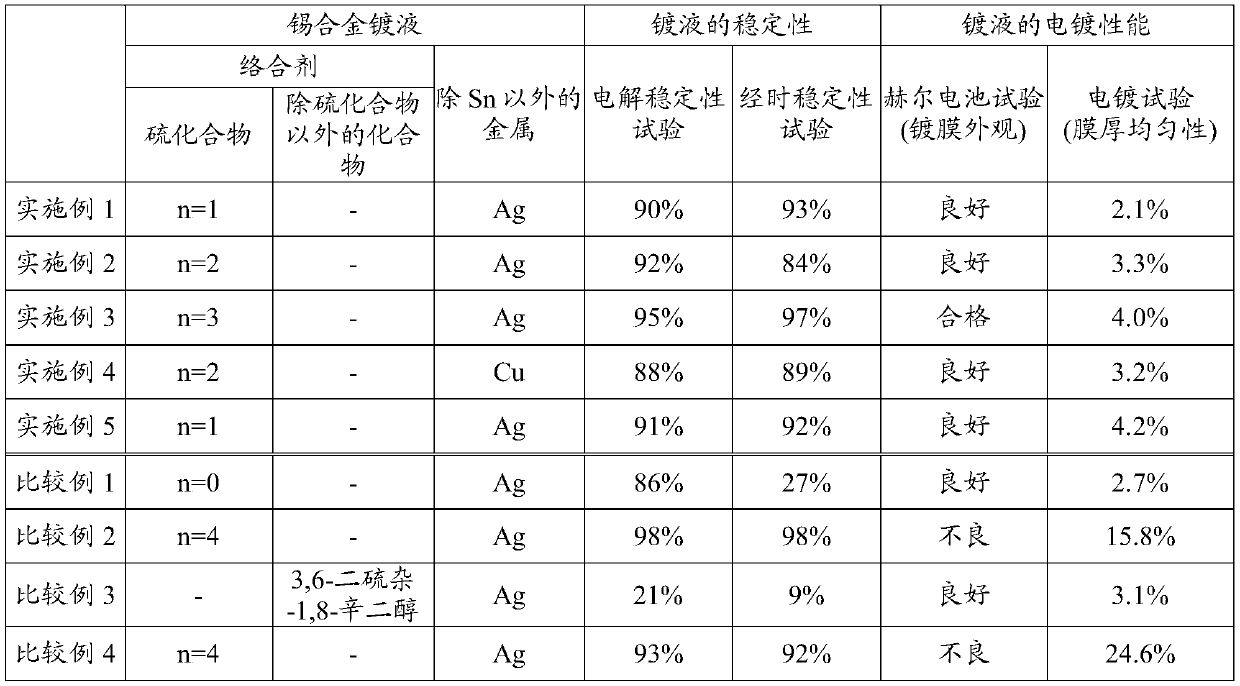

[0067] Next, examples of the present invention will be described in detail together with comparative examples.

[0068] (Building bath for SnAg plating solution)

[0069]

[0070] In the tin methanesulfonate aqueous solution, the methanesulfonic acid as the free acid, the sulfur compound of n=1 of the general formula (1) as the complexing agent, the nonionic surfactant (with the ratio of 50:50 poly A surfactant obtained by adding oxyethylene and polyoxypropylene to ethylenediamine) was mixed and dissolved, and a silver methanesulfonate solution was further added and mixed. Finally, ion-exchanged water was added to build up a SnAg plating solution having the following composition. In addition, an aqueous solution of tin methanesulfonate and an aqueous solution of silver methanesulfonate were prepared by electrolyzing a metal tin plate and a metal silver plate in an aqueous methanesulfonic acid solution, respectively.

[0071] (Composition of SnAg plating solution)

[0072]...

Embodiment 2

[0079] A SnAg plating solution was set up in the same manner as in Example 1 except that a sulfur compound of n=2 of the general formula (1) was used as a complexing agent.

Embodiment 3

[0081] The SnAg plating solution was set up in the same manner as in Example 1 except that a sulfur compound of n=3 of the general formula (1) was used as a complexing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com