Flat type heat pipe and manufacturing method thereof

A manufacturing method and flat technology, applied in the field of heat dissipation, can solve the problems of reducing heat transfer capacity, reducing the reliability of heat pipe production, and water accumulation in steam, so as to improve thermal conductivity, reduce poor adhesion, and ensure reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

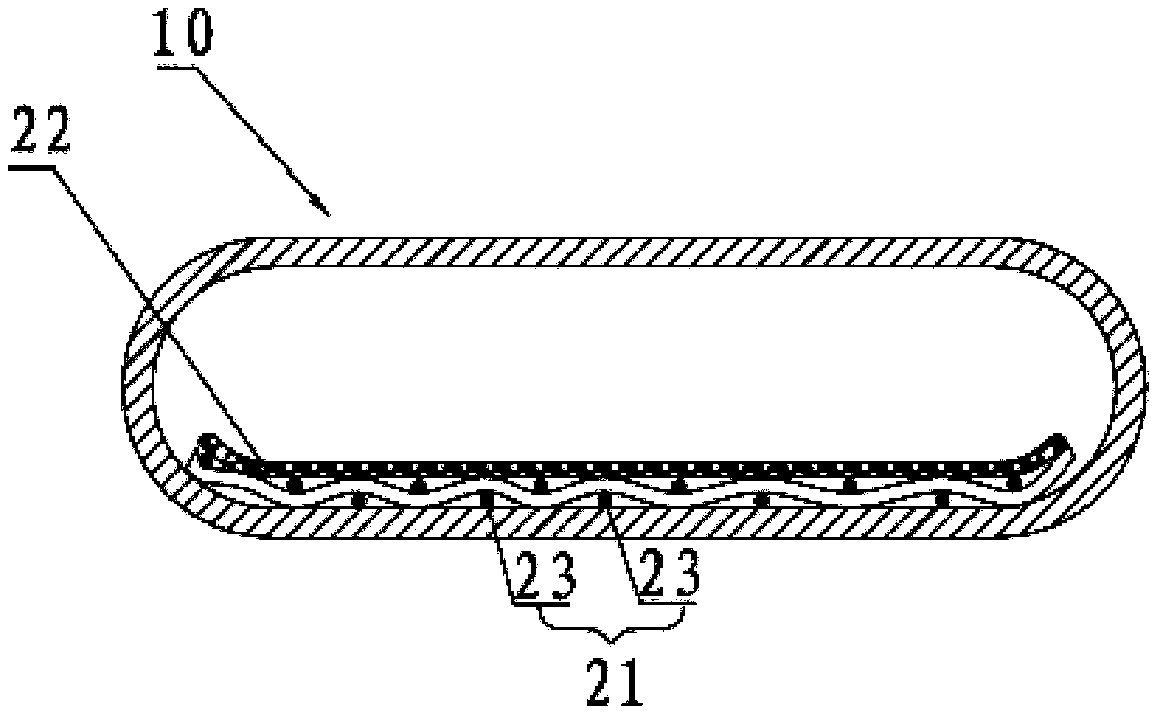

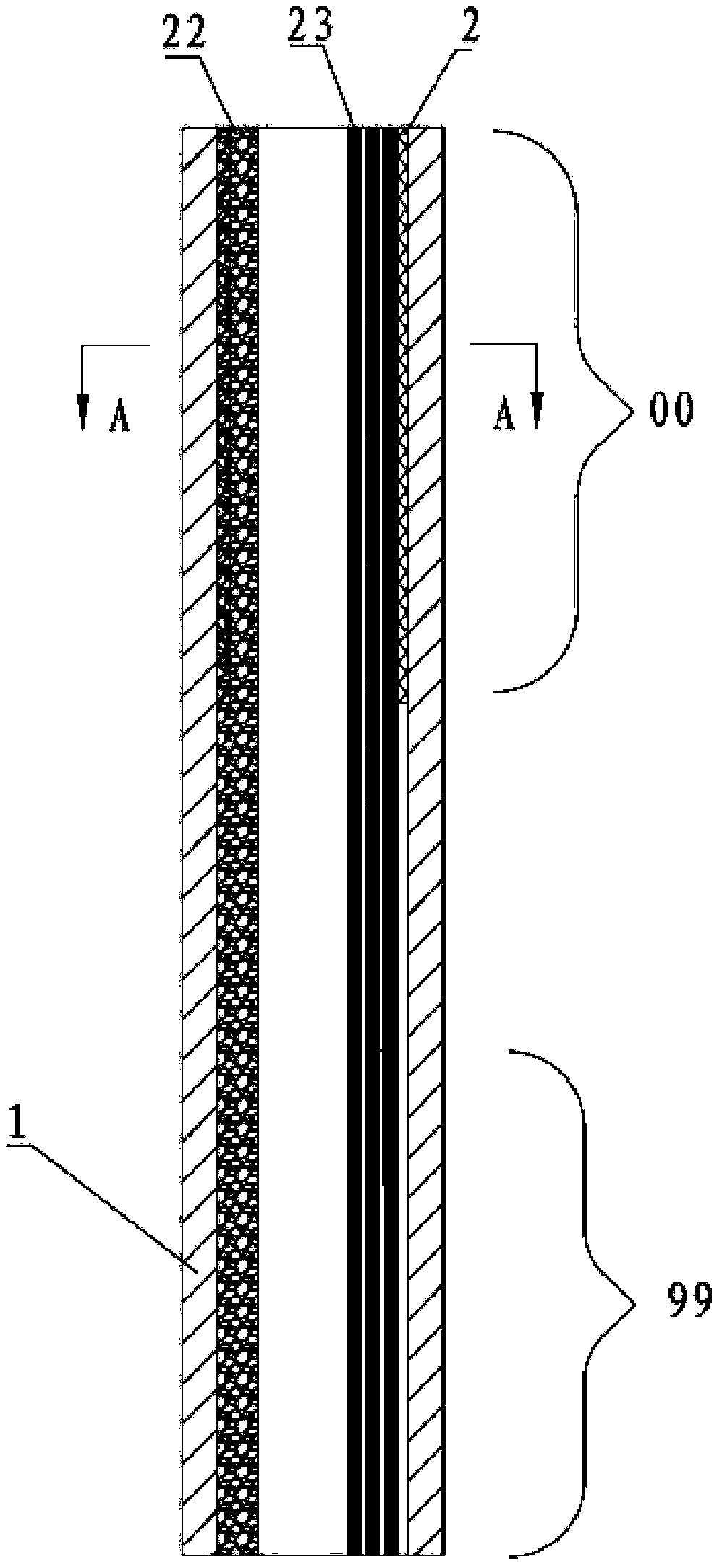

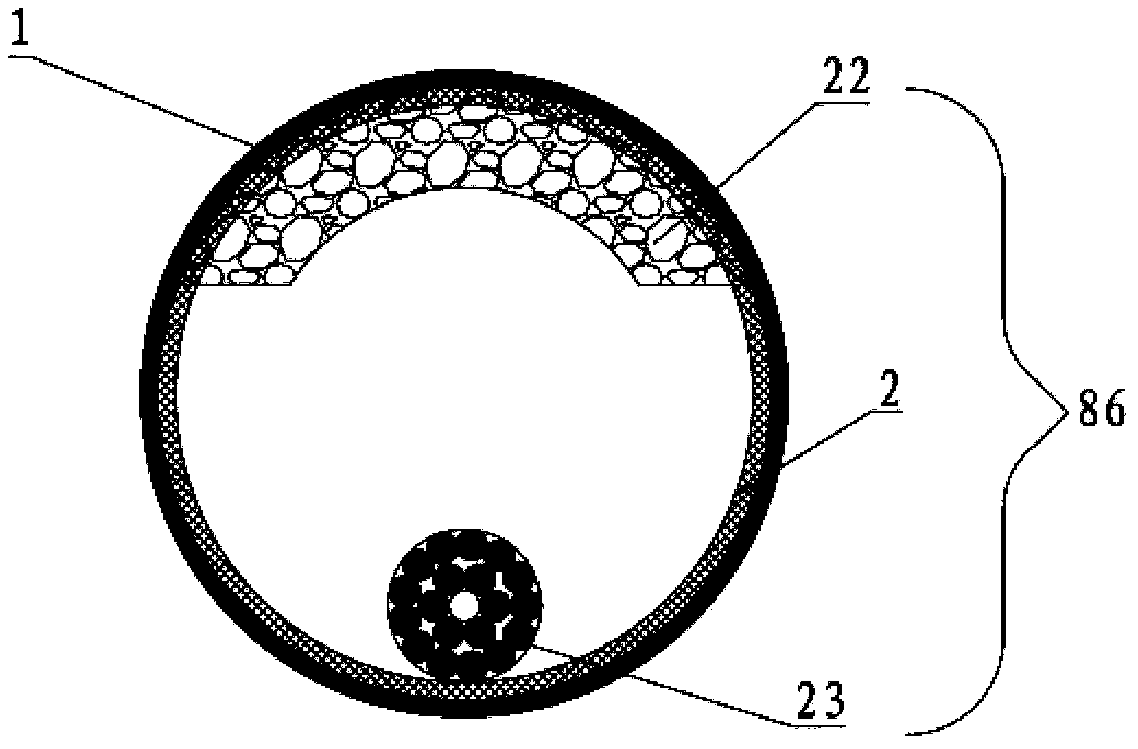

[0033] combine figure 2 with image 3 , the tube body of the heat pipe before being flattened is a circular copper tube, including a tube body 1 and an evaporation section 00 and a condensation section 99 located at both ends of the tube body 1, and a composite sintering section is arranged in the lumen of the tube body 1 capillary structure 86, the composite sintered capillary structure 86 includes a metal wire 23 and a metal mesh, the metal mesh 2 is arranged on the inner peripheral surface of the tube body 1 of the evaporation section, and the metal wire 23 is arranged along the axial direction of the tube body 1 One side of the inner peripheral surface is arranged in a circular shape. As a preferred method, the diameter of the metal wires in this embodiment is less than or equal to 0.6 copper wires. In order to play a bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com