Plate-fin type heat exchanger core

A plate-fin heat exchanger and plate-fin technology, applied in the field of plate-fin heat exchangers, can solve the problems of inability to realize refined production, high leakage rate of core body, low assembly efficiency, etc., and achieve easy distribution of production, Reduced leakage rate and simple parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

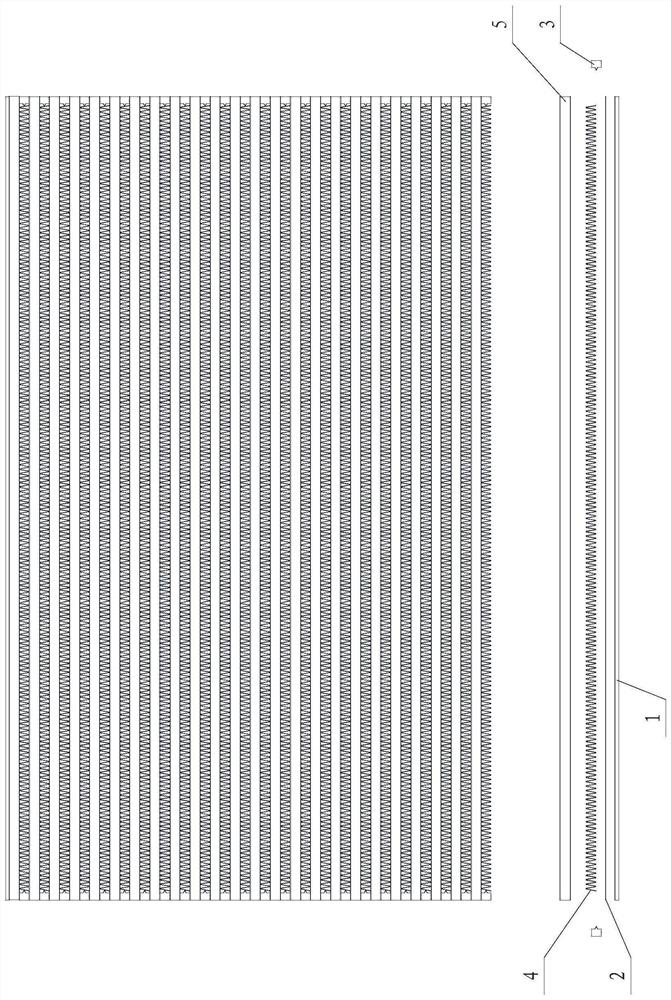

[0032] Such as Figure 5-9 As shown, the core body of the plate-fin heat exchanger of the present invention includes a side plate 1, a heat dissipation strip 4, a cooling pipe assembly 7 and a seal assembly 8, wherein a plurality of heat dissipation strips 4 are arranged between the side plates 1 on both sides. And a plurality of cooling pipe assemblies 7, each cooling belt 4 and each cooling pipe assembly 7 are arranged alternately.

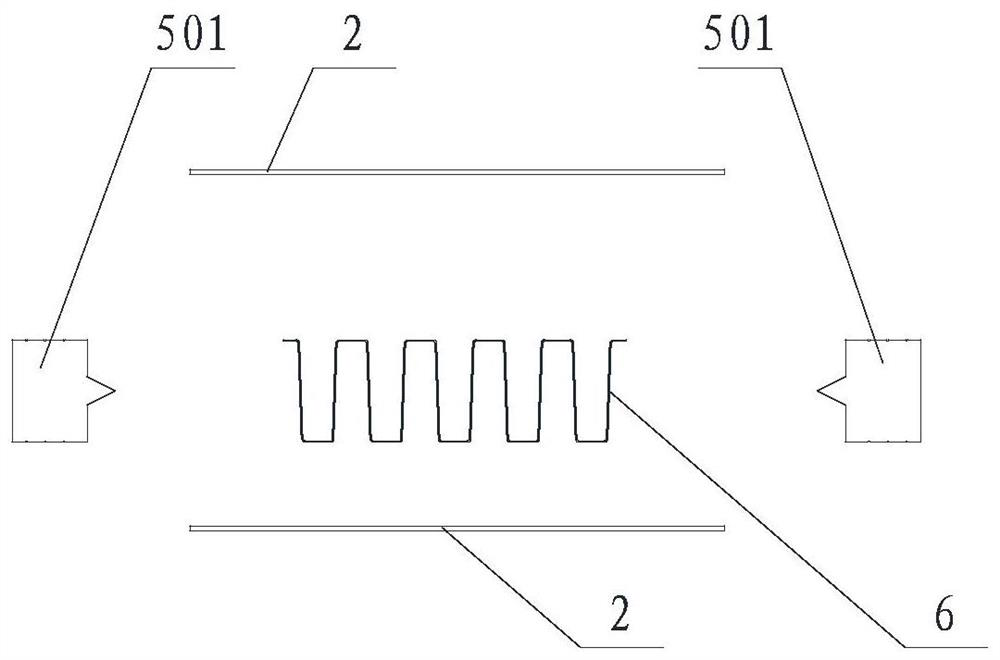

[0033] The cooling pipe assembly 7 of this embodiment includes a plate-fin single-hole tube 701 and an inner fin 6 welded in the plate-fin single-hole tube 701. The plate-fin single-hole tube 701 is integrally formed, and the sealing performance is obvious Higher than the sealing performance of the existing core body through the internal channel 5 that is welded together, the leakage rate of the core body is reduced; the end face of the plate-fin single-hole tube 701 in this embodiment is a rectangle, and the inner surfaces of the left and right...

Embodiment 2

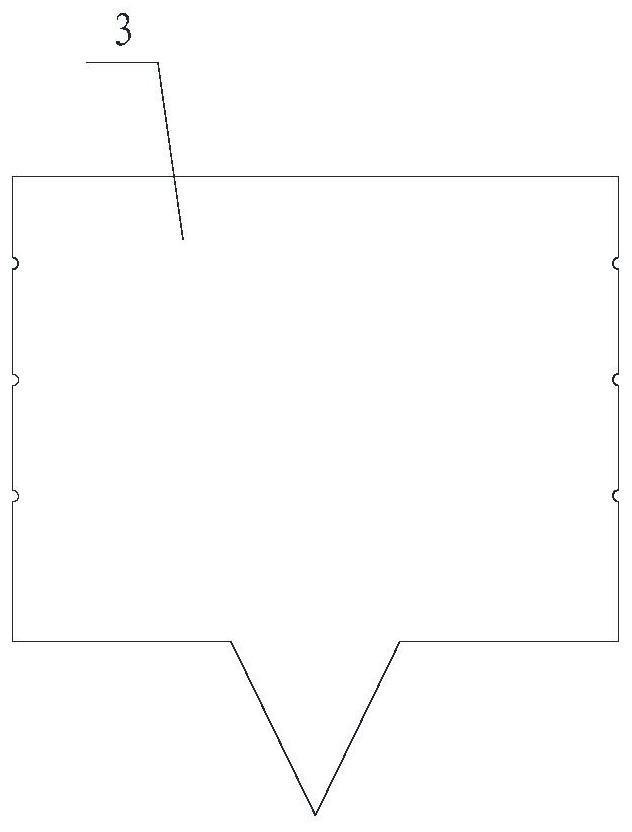

[0041] Such as Figure 5-7 and Figure 10As shown, the difference between the present embodiment and the first embodiment is that the welded assembly of the present embodiment includes an extruded groove 805 and a separator / double-coated aluminum strip 806, and extruded seals are provided on both sides of the end surface of the extruded seal 801. Groove 805, there are two extrusion grooves 805 on each side in this embodiment, and the separator / double-coated aluminum strip 806 on each side is extruded in the extrusion groove 805, and then fixed with the extrusion seal 801; in this embodiment Both ends of the separator / double-clad aluminum strip 806 are bent toward one side of the extruded seal 801, and then bent outward, and the bent part is extruded in the extruded groove 805. When it is a partition, there is solder on the inner and outer surfaces of the partition, and the solder melts during brazing so that the partition is welded and sealed with the extrusion seal 801 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com