Method and device for producing electronic grade phosphorus oxychloride

A technology of phosphorus oxychloride and production method, which is applied in directions such as phosphorus halide/oxyhalide and the like, can solve the problems of yellow phosphorus purification process pollution, high production risk, low production efficiency and the like, and achieves low production cost and low environmental pollution. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

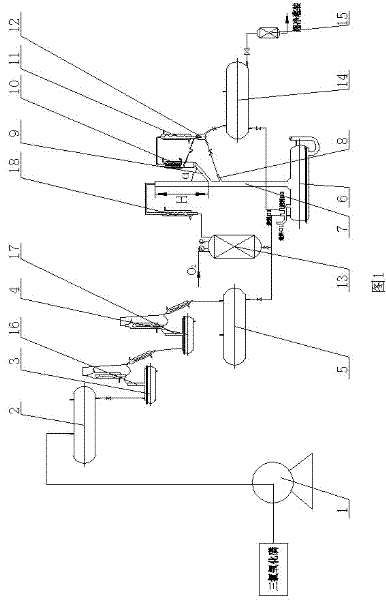

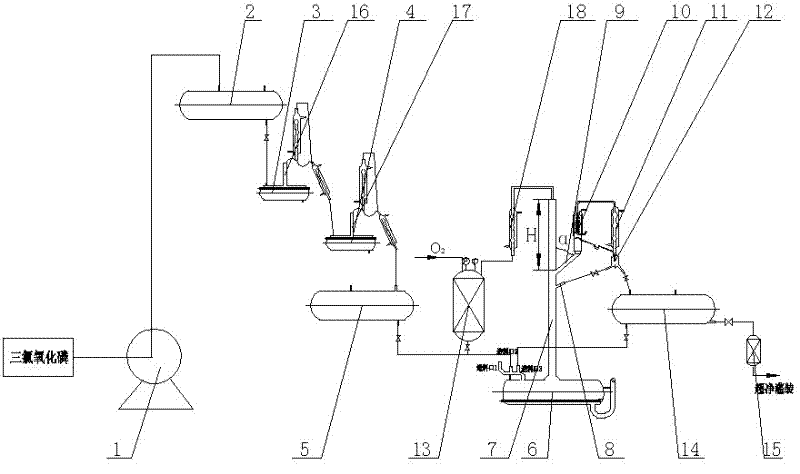

[0015] The present invention will be further described with reference to the accompanying drawings and examples.

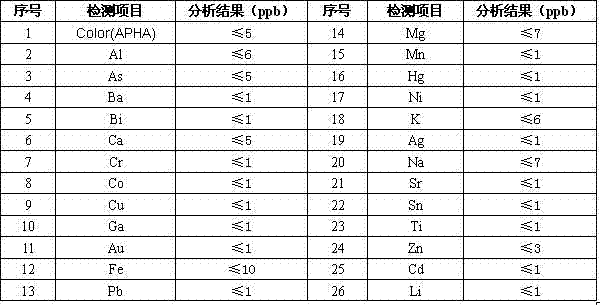

[0016] The production method of the invention can achieve an excellent separation and purification effect only by one rectification, which is completely different from the multiple rectification and purification methods in the prior art. The raw material of the invention is industrial phosphorus oxychloride with content ≥ 98.5%.

[0017] Concrete preparation method of the present invention and device are as follows: the production method of electronic grade phosphorus oxychloride of the present invention comprises the following steps:

[0018] ①Put industrial phosphorus oxychloride into the container, and then add potassium permanganate oxidant into the container according to 1 / 10000 to 3 / 10000 of the total amount of phosphorus oxychloride. Add sodium bromide or hexadecyltrimethylammonium bromide additive from 1 to 3 / 1000, stir evenly and transport it to the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com