Ultrathin vapor chamber and manufacturing method thereof

A manufacturing method and vapor chamber technology, applied in the field of heat conduction, can solve problems such as large flow resistance, reduced heat transfer capacity of vapor chamber, and capillary force drop of liquid-absorbing cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

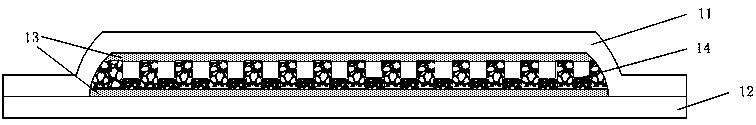

[0064] like figure 1 An ultra-thin vapor chamber is shown, which is composed of an upper shell (11), a lower shell (12), a liquid-absorbing core (13), a porous metal support layer (14) and a working medium. closed chamber;

[0065] The upper shell (11) and the lower shell (12) are copper foils with a thickness of 0.05 mm, and a layer of aluminum oxide barrier film is deposited on the outer surface of the copper foils;

[0066] The liquid-absorbing core (13) is obtained by sintering copper balls with an average particle size of 0.03 mm on the inner surfaces of the upper shell (11) and the lower shell (12), and its thickness is 0.06 mm;

[0067] The porous metal support layer (14) is a patterned structure, which is arranged between two layers of liquid-absorbing cores (13), and adopts foamed copper with a three-dimensional mesh structure with open pores. The thickness of the foamed copper is 0.4 mm, and the average pore diameter is It is 0.1mm, prepared by setting grooves para...

Embodiment 2

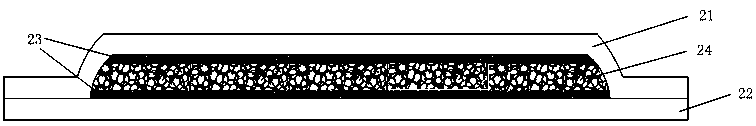

[0076] like figure 2 An ultra-thin vapor chamber is shown, which is composed of an upper shell (21), a lower shell (22), a liquid-absorbing core (23), a porous metal support layer (24) and a working medium. Chamber;

[0077] The upper shell (21) and the lower shell (22) are copper foils with a thickness of 0.1 mm;

[0078] The liquid-absorbing core (23) is made by superimposing two layers of foamed copper (foamed copper specification: the number of holes (PPI) is 95, the thickness is 1.8mm, and the surface density is 280g / m 2 ) compressed porous medium, the compressed copper foam has a porosity of 70% and a thickness of 0.2 mm. A layer of copper oxide nanosheet structure with superhydrophilic properties is prepared on the surface of the foamed copper. The structure of the nanosheet is as follows Figure 8 shown;

[0079] The porous metal support layer (24) has a single structure and is arranged between two layers of liquid-absorbing cores (23). preparation;

[0080] Use ...

Embodiment 3

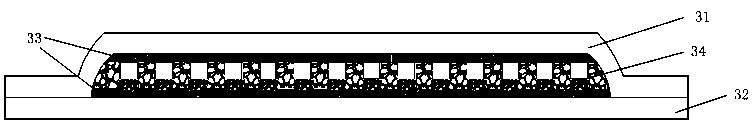

[0088] like image 3 An ultra-thin vapor chamber is shown, which is composed of an upper shell (31), a lower shell (32), a liquid-absorbing core (33), a porous metal support layer (34) and a working medium. Chamber;

[0089] The upper shell (31) and the lower shell (32) are aluminum foils with a thickness of 0.5 mm, the surface of the aluminum foil is covered with a layer of tin film, and the inner surfaces of the upper and lower shells are connected to the liquid-absorbing core (33);

[0090] The liquid-absorbing core (33) is a porous medium obtained by compressing a layer of foamed copper. The foamed copper is stretched before compression. After stretching, the aspect ratio of the internal pore diameter is 3:1. The compressed foamed copper pores The ratio is 50%, and the thickness is 0.5mm;

[0091] The porous metal support layer (34) has a patterned structure and is arranged between two layers of liquid-absorbing cores (33). , prepared by setting grooves parallel to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com