Planar super-conduction heat pipe and preparation method thereof

A superconducting heat pipe and planar technology, which is applied in the field of heat pipes for heat transfer, can solve problems such as insufficient capillary force, restricting heat dissipation performance of heat pipes, disturbing steam flow, etc., and achieve good heat exchange effect, excellent capillary pressure and reflux ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate those of ordinary skill in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

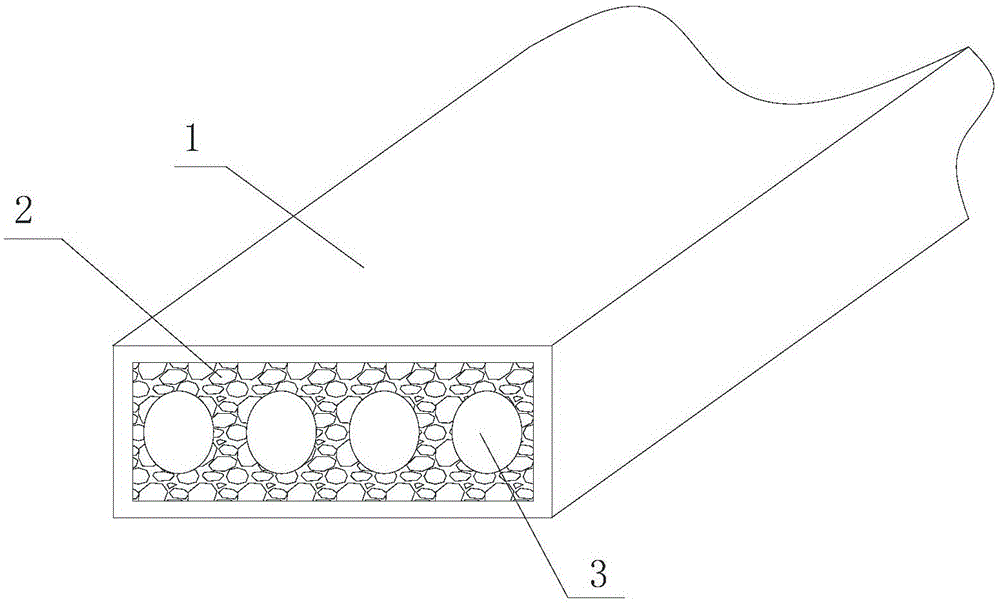

[0024] like figure 1 As shown, a planar superconducting heat pipe includes: an airtight casing 1, a liquid-absorbing core 2 formed in the casing 1, and a steam chamber 3, which is characterized in that the steam chamber 3 is in the shape of a porous double arch.

[0025] Wherein, the shell 1 is made of copper skin, the thickness of the shell is between 3-50mm, and the wall thickness of the shell is controlled between 0.5mm-1mm. The liquid-absorbing core 2 is in the form of foam, and the equivalent diameter of the pores of the liquid-absorbing core is larger than the wall thickness of the shell 1 . Described steam chamber 3 is a vacuum chamber, and the vacuum degree of steam chamber is 10 -4 to 10 -1 Pa.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com