Resin composition, covering film, laminate, resin coated copper foil and binding sheet

A resin composition, laminate technology, applied in the direction of coatings, adhesives, layered products, etc., can solve the problems of low dielectric properties, difficult parts for FPC, low polarity, etc., to achieve high adhesion, solder resistance, etc. Excellent paste reflow properties and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

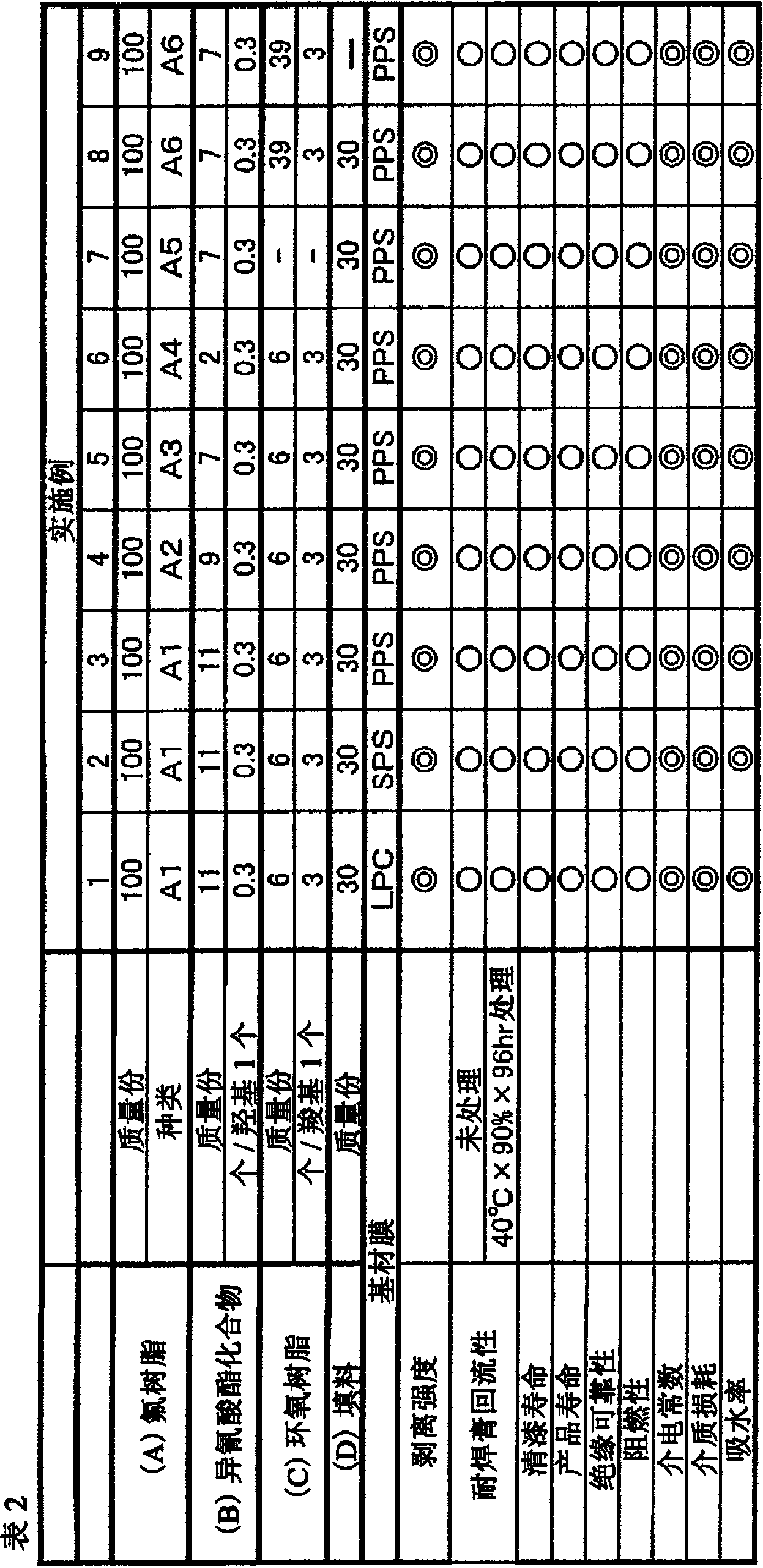

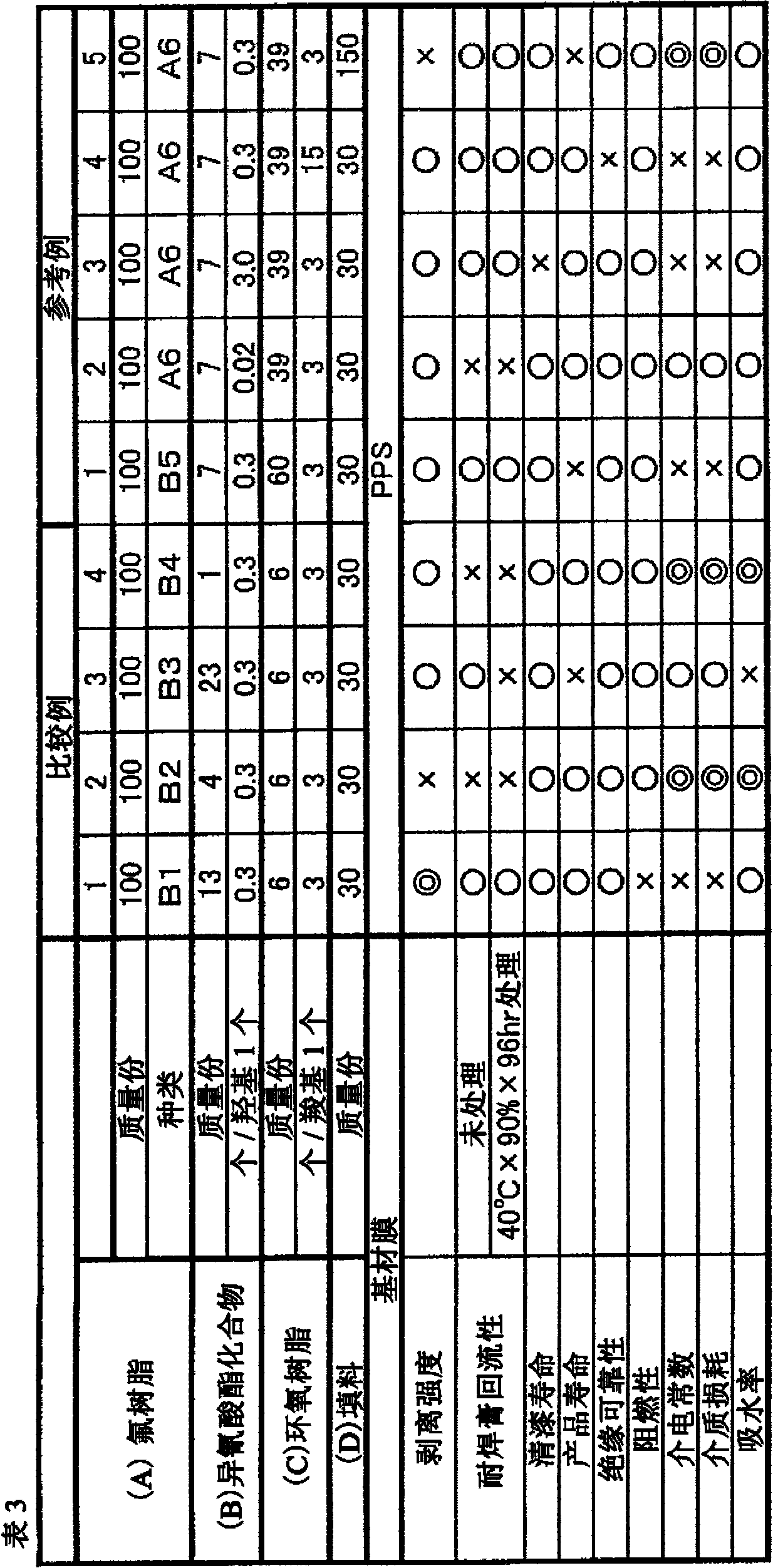

[0110] Hereinafter, the present invention will be further specifically described by way of examples and comparative examples, but the present invention is not limited to these examples.

[0111] In Examples and Comparative Examples, measurements and evaluations of various physical properties were performed by the following methods.

[0112] Hydroxyl equivalent

[0113] Measurement was performed in accordance with JIS K1557-1. Specifically, measurement was performed as follows.

[0114] 10 mL of acetic anhydride solution (prepared with 400 mL of ethyl acetate, 4 g of perchloric acid, and 50 mL of acetic anhydride) was added to 3 g of the sample, and stirred for 15 minutes. 2 mL of water and 10 mL of a pyridine aqueous solution (prepared with 300 mL of pyridine and 100 mL of water) were added, followed by stirring for 5 minutes. Then, another 10 mL of aqueous pyridine was added.

[0115] The hydroxyl equivalent was calculated by titration with an ethanol solution of 0.5 mol / ...

manufacture example 1

[0208] A 1000 mL stainless steel autoclave was filled with 340 parts by mass of butyl acetate, 132 parts by mass of vinyl pivalate, 62 parts by mass of hydroxybutyl vinyl ether, 36 parts by mass of ethyl vinyl ether, and 2 parts by mass of crotonic acid And 7 mass parts of diisopropyl peroxydicarbonates were degassed under reduced pressure after cooling to 0 degreeC. Fill the obtained mixture with 30 parts by mass of hexafluoropropylene, heat to 40° C. with stirring, and allow them to react for 24 hours. The pressure in the reactor increases from 5 kg / cm 2 down to 2kg / cm 2 The reaction was stopped at a certain time, and fluororesin A1 was obtained.

[0209] The obtained fluororesin A1 was analyzed by 19F-NMR, 1H-NMR and combustion method, and it was found that it contained 11.1% of hexafluoropropylene units, 21.9% of ethyl vinyl ether units, and 44.0% of vinyl pivalate units by moles. 1. A copolymer of 22.0% hydroxybutyl vinyl ether unit and 1.0 / % crotonic acid unit, the flu...

manufacture example 2~6

[0210] Manufacturing Examples 2-6, Comparative Examples 1-5

[0211] Fluororesins A2 to A6 and B1 to B5 were obtained in the same manner as in Example 1 except that the filling amount of the monomer was changed.

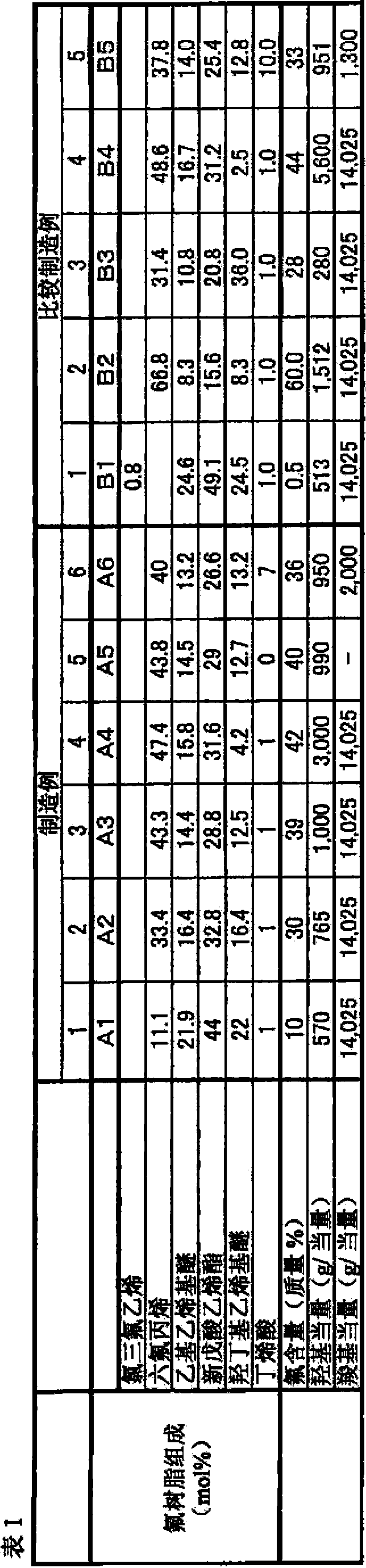

[0212] Table 1 shows the composition, fluorine content, hydroxyl equivalent, and carboxyl equivalent of the obtained fluororesin.

[0213] Table 1

[0214]

[0215] Manufacture of resin composition for FPC

[0216] In Examples and Comparative Examples, the following base films were used.

[0217] Liquid crystal polymer film (LCP) (manufactured by Kuraray, Vecster, thickness 25 μm)

[0218] Syndiotactic polystyrene (SPS) (manufactured by Idemitsu Kosan Co., Ltd., Xarec, thickness 25 μm)

[0219] Polyphenylene sulfide (PPS) (manufactured by Toray Corporation, Torayner, thickness 25 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com