Method for manufacturing heat-pipe-parallel-structure-like foamy copper vapor plate

A technology of foamed copper and soaking plate, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of high thermal resistance and poor capillary characteristics of thermal circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

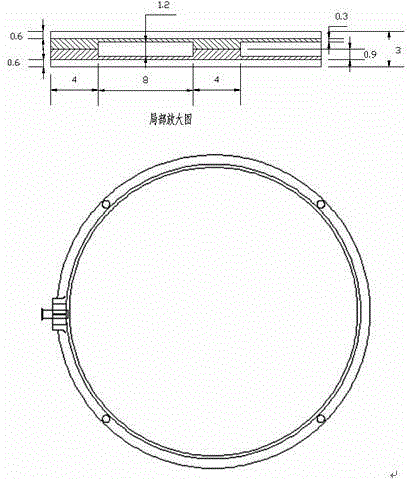

[0022] Example 2, adopting the thickness that the present invention makes is 3 millimeters, and diameter is the vapor chamber of f100 mm, and its structure is as Figure 4 As shown, the specific method is as follows:

[0023] (1) Select two oxygen-free copper sheets with a thickness of 0.6 mm. The diameter of the lower cover plate is f100mm. After stamping or machining, the outer diameter of the upper cover plate is the same as the diameter of the lower cover plate, both of which are f100mm. In this way, after the upper and lower cover plates are combined, a vapor chamber with a diameter of f100mm is formed, and the edge size of the upper and lower cover plates for packaging is about 4mm, such as Figure 4 shown.

[0024] (2) The upper cover plate is made into a circular plate structure with an inner cavity depth of 1.8mm by stamping or machining, and the width of the edge is about 4mm, such as Figure 4 shown. The stepped copper foam structure used is as Figure 4 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com