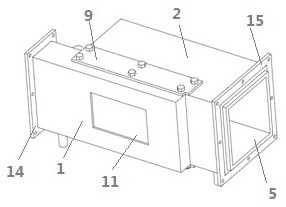

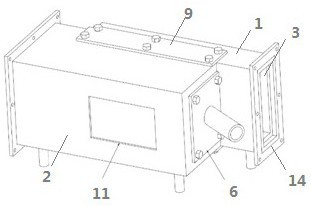

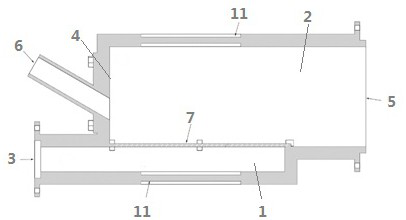

CMC flame tube test box and test method thereof

A flame tube and test box technology, which is applied in the field of aero-engine test, can solve the problems of poor device versatility, high cost, and difficult test, and achieve the effect of ensuring sealing and enhancing the effect of backflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific examples.

[0041] In this embodiment, the gas film holes of the test piece are circular, with a diameter of 0.6 mm, a hole spacing of 4 mm, and an inclination angle of 45°. The import parameters of the test chamber are as follows:

[0042] Test chamber import parameters

[0043] parameter name High temperature air velocity (m / s) Low temperature air velocity (m / s) High temperature air flow temperature (K) Low temperature airflow temperature (K) Inlet pressure (MPa) design value 80 10 1400 800 3.0

[0044] In order to simplify the calculation and design quickly, without affecting the reliability of the design, the following assumptions are made:

[0045] 1) Look at the air as an ideal gas, and use the ideal gas state equation to calculate the density and pressure in the calculation;

[0046] 2) In the calculation, the diffusion process is regarded as adia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com