Flat type radiating pipe and manufacturing method thereof

A manufacturing method and technology of heat dissipation pipes, which are applied in the field of heat dissipation, can solve the problems of increased thermal resistance, decreased heat transfer of heat dissipation pipes, water accumulation in adiabatic sections and condensation sections of heat dissipation pipes, etc. The effect of a substantial reduction in heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

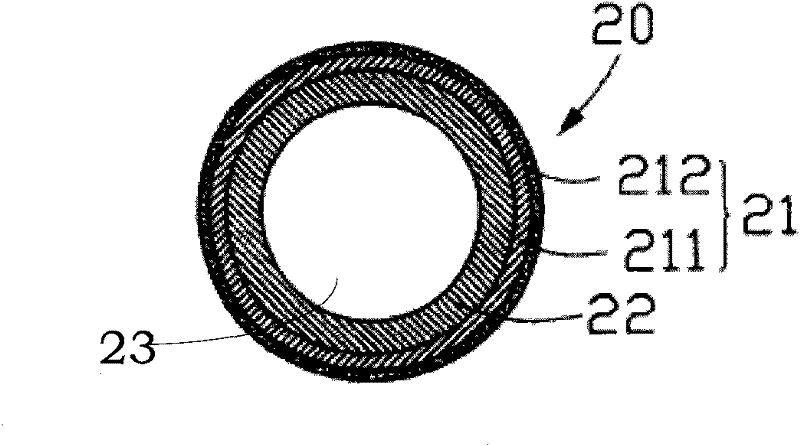

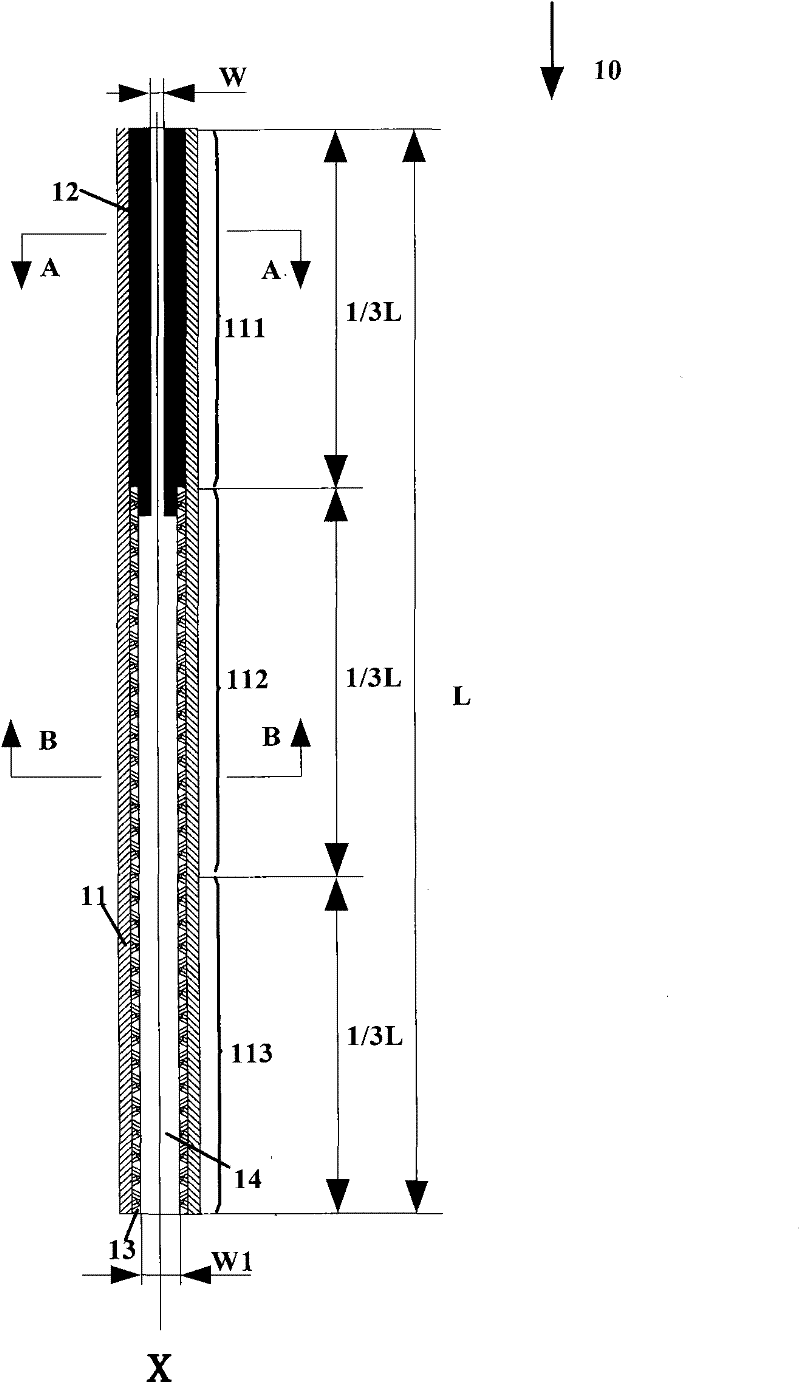

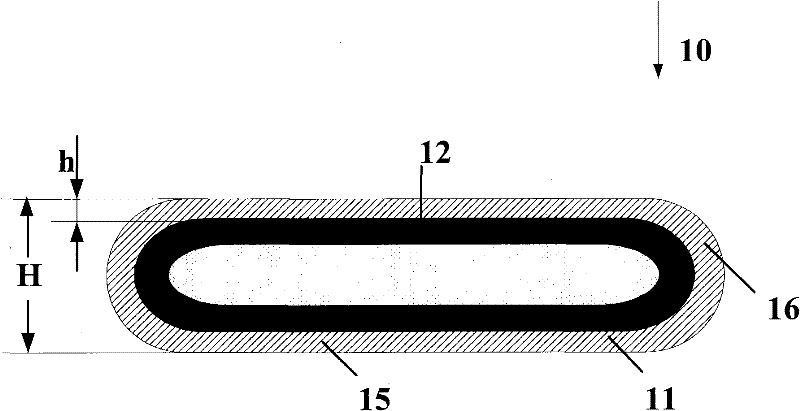

[0041] The invention provides a novel composite capillary structure heat pipe. The main body of the heat pipe adopts a powder sintered capillary structure. In order to improve the problem of water accumulation in the heat insulation section and the condensation section caused by the relatively small lumen width between the capillary structures of the heat dissipation pipe, the invention replaces the powder sintered structure with a wire mesh structure with a thinner capillary structure layer in the heat insulation section and condensation section of the heat dissipation pipe , which greatly increases the volume of the main gas channel in the heat insulation section and the condensation section after being flattened, that is, in the axial section of the heat pipe, the width of the lumen between the capillary structures is increased, and the heat pipe is flattened to a very large extent. The problem of water accumulation after thinning. The return efficiency of the working mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com