Pulverized coal preparation system and method

A pulverized coal preparation and pulverized coal technology, which is applied in the field of coal chemical industry, can solve the problems of high energy consumption and achieve the effects of reducing investment, avoiding leakage and improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

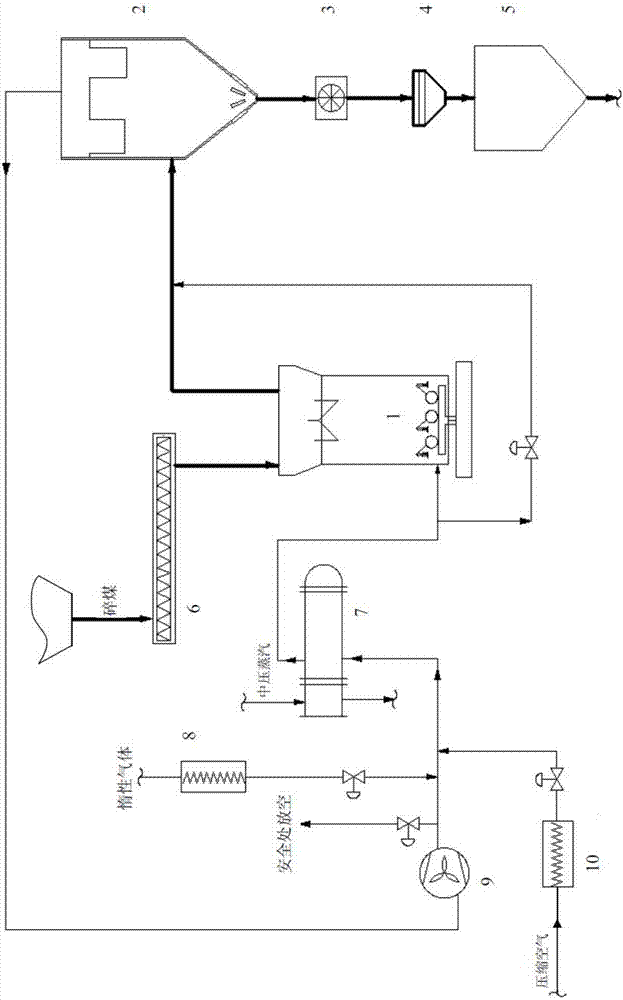

[0048] See figure 1 , which is a schematic diagram of the pulverized coal preparation system provided in this embodiment. The flow direction of the material is marked in the figure. Gas heater 7, coal powder collector 2, rotary feeder 3, fiber separator powder 4, coal storage bin 5, circulation fan 9, air preheater 10 and inert gas preheater 8; the coal pulverizer The circulating gas heater 7 is a steam heat exchanger; the pulverized coal collector 2 is a gas-solid separator; the air preheater is an electric heater; the inert gas preheater is an electric heater;

[0049] The coal pulverizer 1 is provided with a pulverized coal inlet, a circulating gas inlet and a circulating gas outlet; the circulating gas outlet is connected to the material inlet of the pulverized coal collector 2 through a pipeline, and the solids of the pulverized coal collector 2 The outlet is connected to the pulverized coal storage bin through a pipeline; the gas outlet of the pulverized coal collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com