Patents

Literature

39results about How to "Reduce venting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

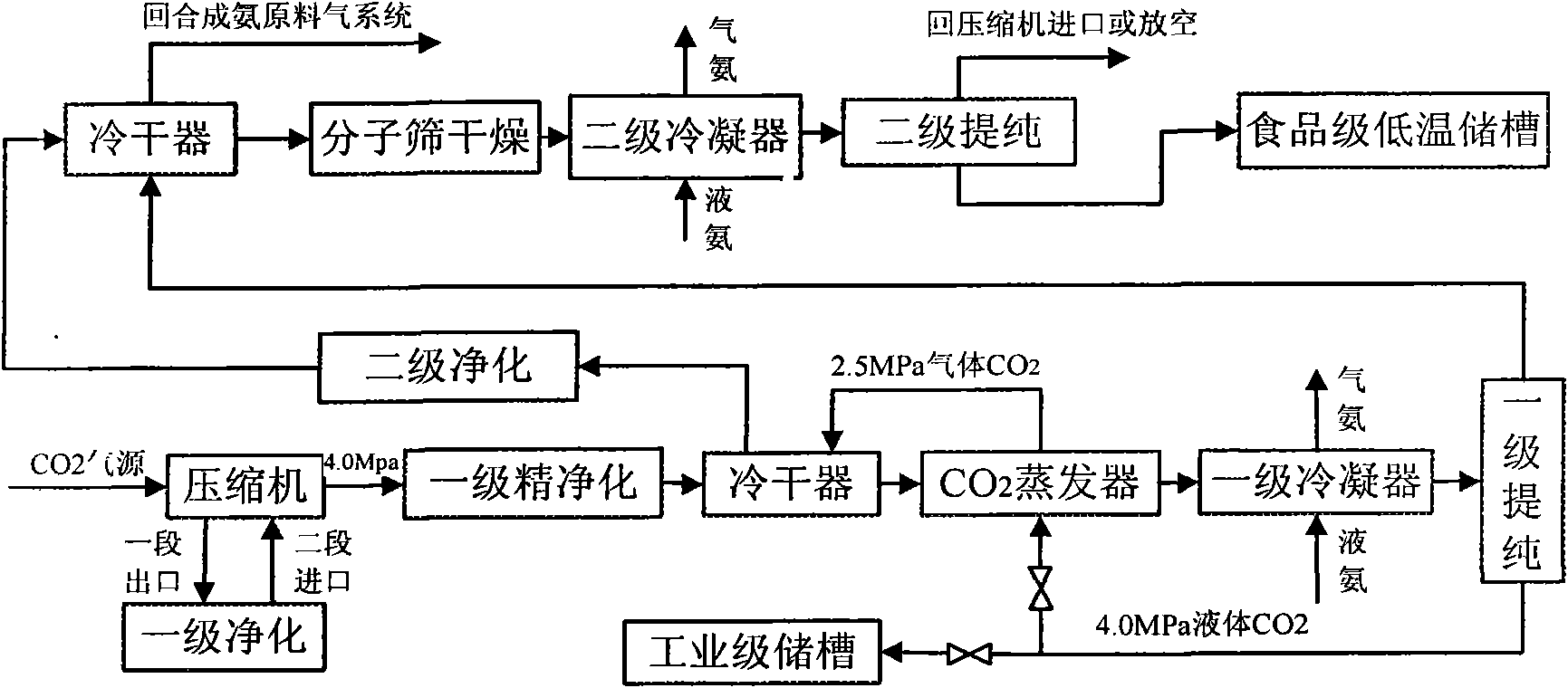

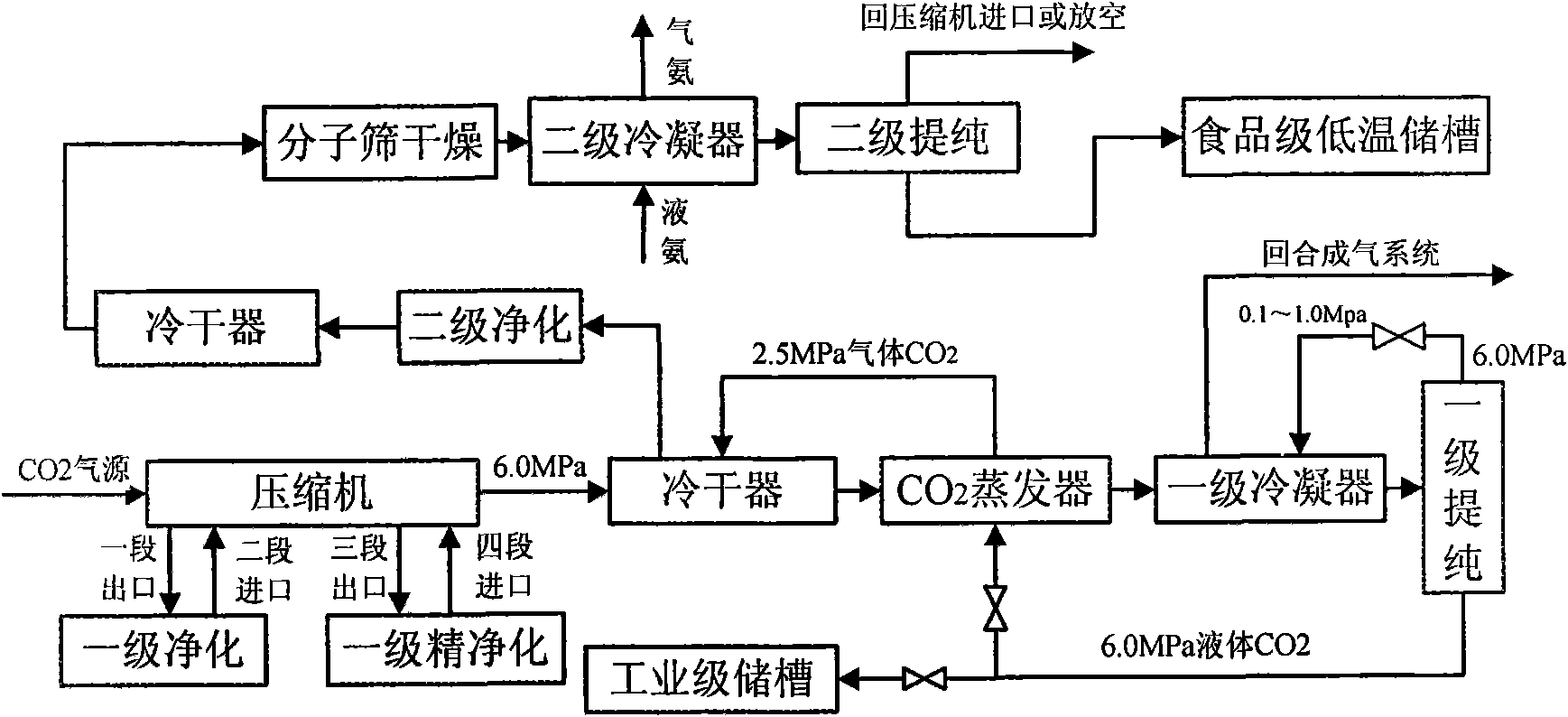

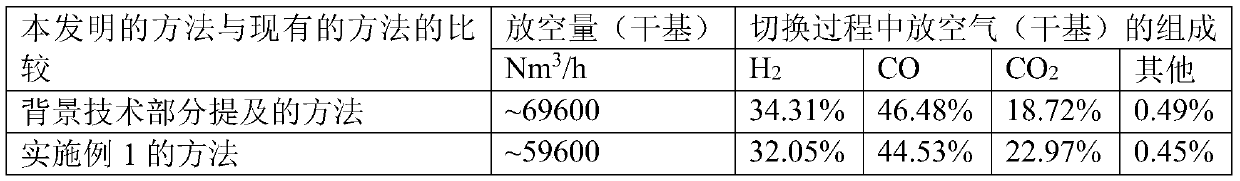

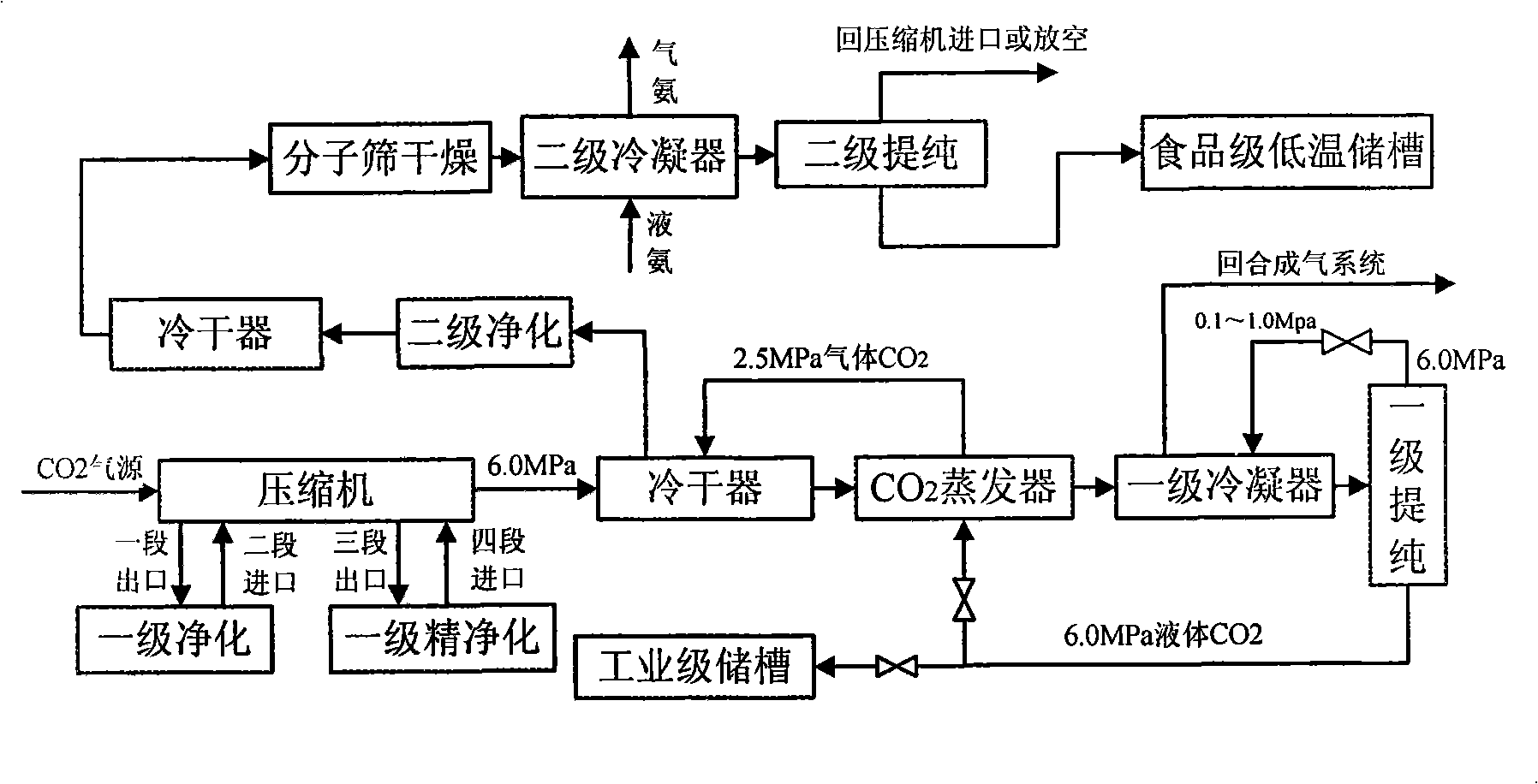

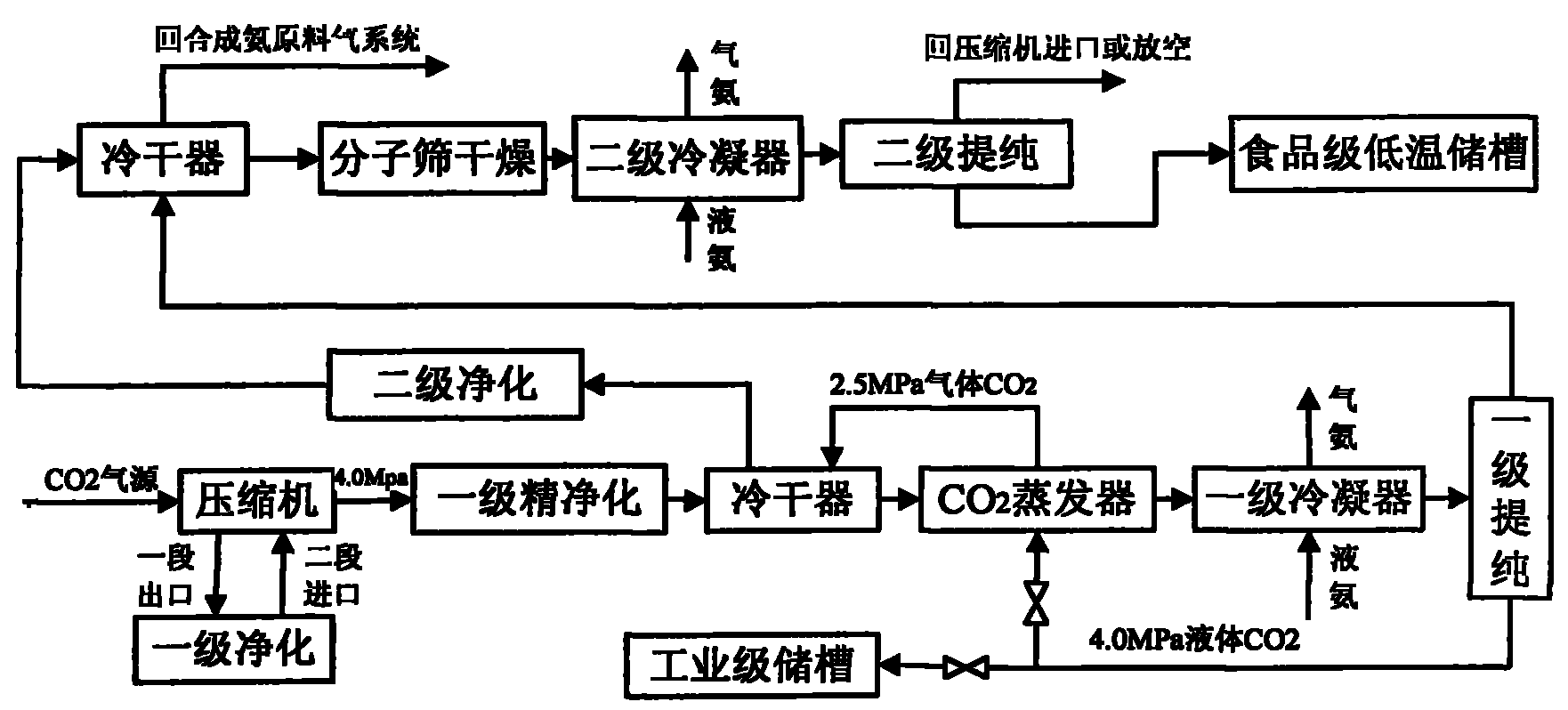

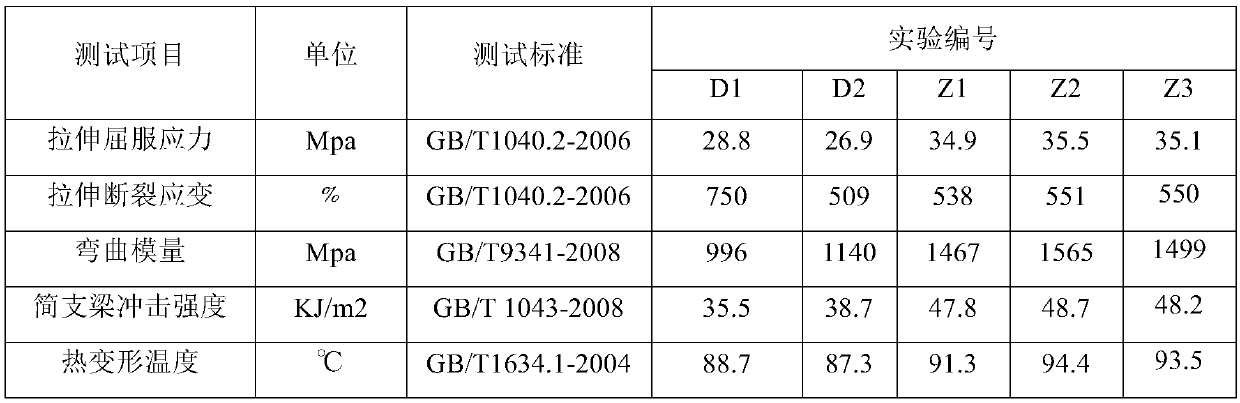

Method for coproducing or singly producing food grade carbon dioxide and industrial grade carbon dioxide by utilizing industrial waste gas

ActiveCN101538040AHigh recovery rateReduce ventingCarbon compoundsChemical industryEnergy consumptionToxic industrial waste

Owner:重庆川茂化工科技有限公司

Method for circularly and rapidly pre-vulcanizing sulfur tolerant shift catalyst and carrying out segmental pre-vulcanizing by utilizing sulfur tolerant shift catalyst

ActiveCN103657741AThe vulcanization method is simpleHeating up fastCatalyst activation/preparationSocial benefitsVulcanization

The invention relates to a segmental pre-vulcanizing method of a sulfur tolerant shift catalyst in a multi-segment conversion process, particularly relates to a method for rapidly pre-vulcanizing cobalt-molybdenum-series sulfur tolerant shift catalysts and belongs to the technical field of pretreatment of the sulfur tolerant shift catalyst. According to the method, aiming at the situations of the temperature raising and the slow vulcanizing speed caused due to insufficient vulcanizing conditions, a segmental vulcanizing method is utilized, namely the rapid pre-vulcanizing of a first-segment furnace is reinforced to raise the temperature of a subsequent second-segment furnace; first-segment vulcanizing conditions are reinforced to guarantee the vulcanization of the catalyst so as to realize the rapid, efficient and complete vulcanization, meanwhile, the temperature of a subsequent second-segment bed is raised by high-temperature vulcanized gas in a rapid vulcanizing process, and the subsequent working segments are similarly processed, so that the vulcanizing and temperature raising time is greatly shortened, and the vulcanizing cost is lowered; by utilizing a circular vulcanizing manner, the emptying quantity is few, the overtemperature is avoided, the vulcanizing process is convenient and safe, the pollution is light, and the method has remarkable economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP

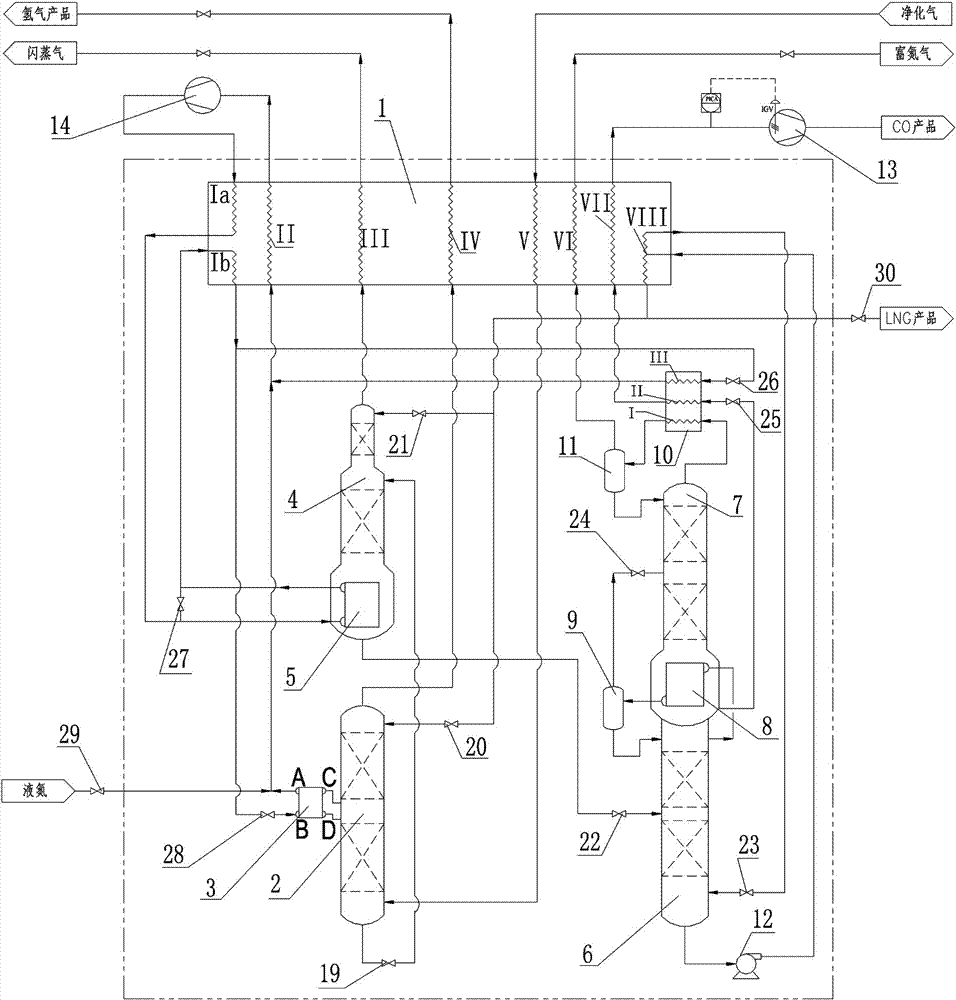

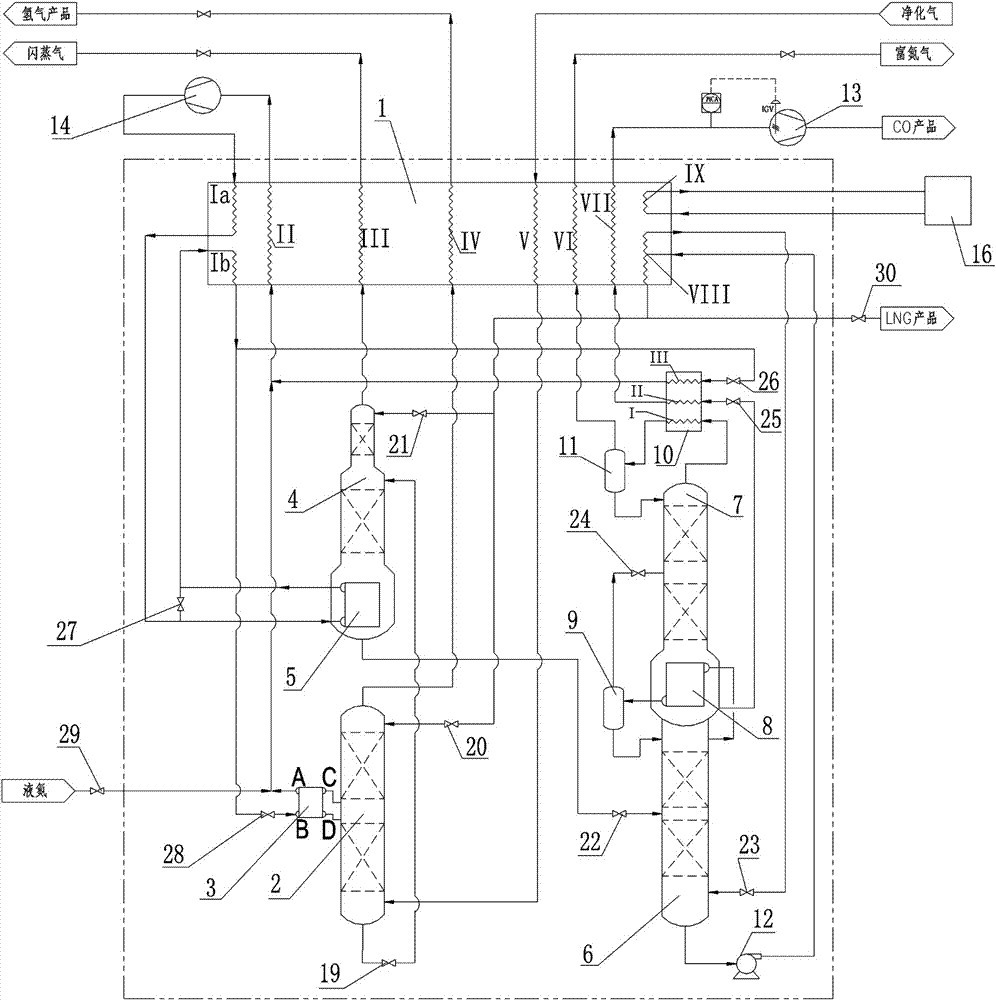

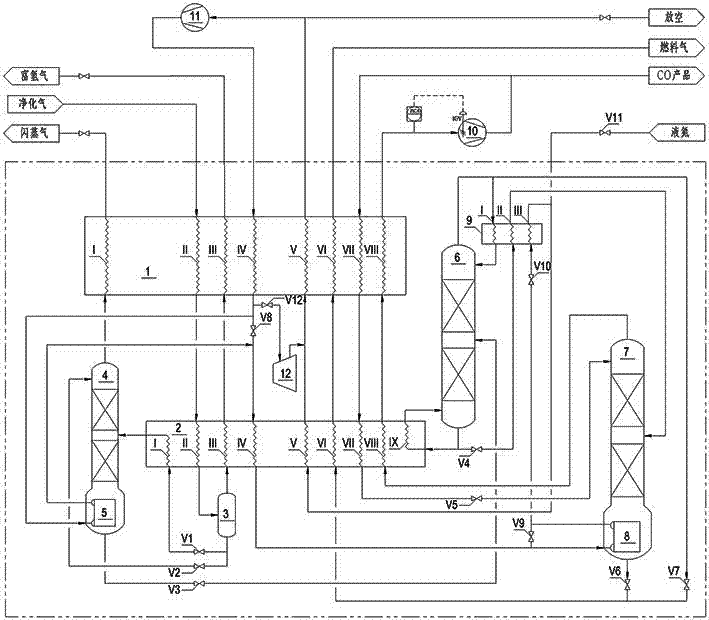

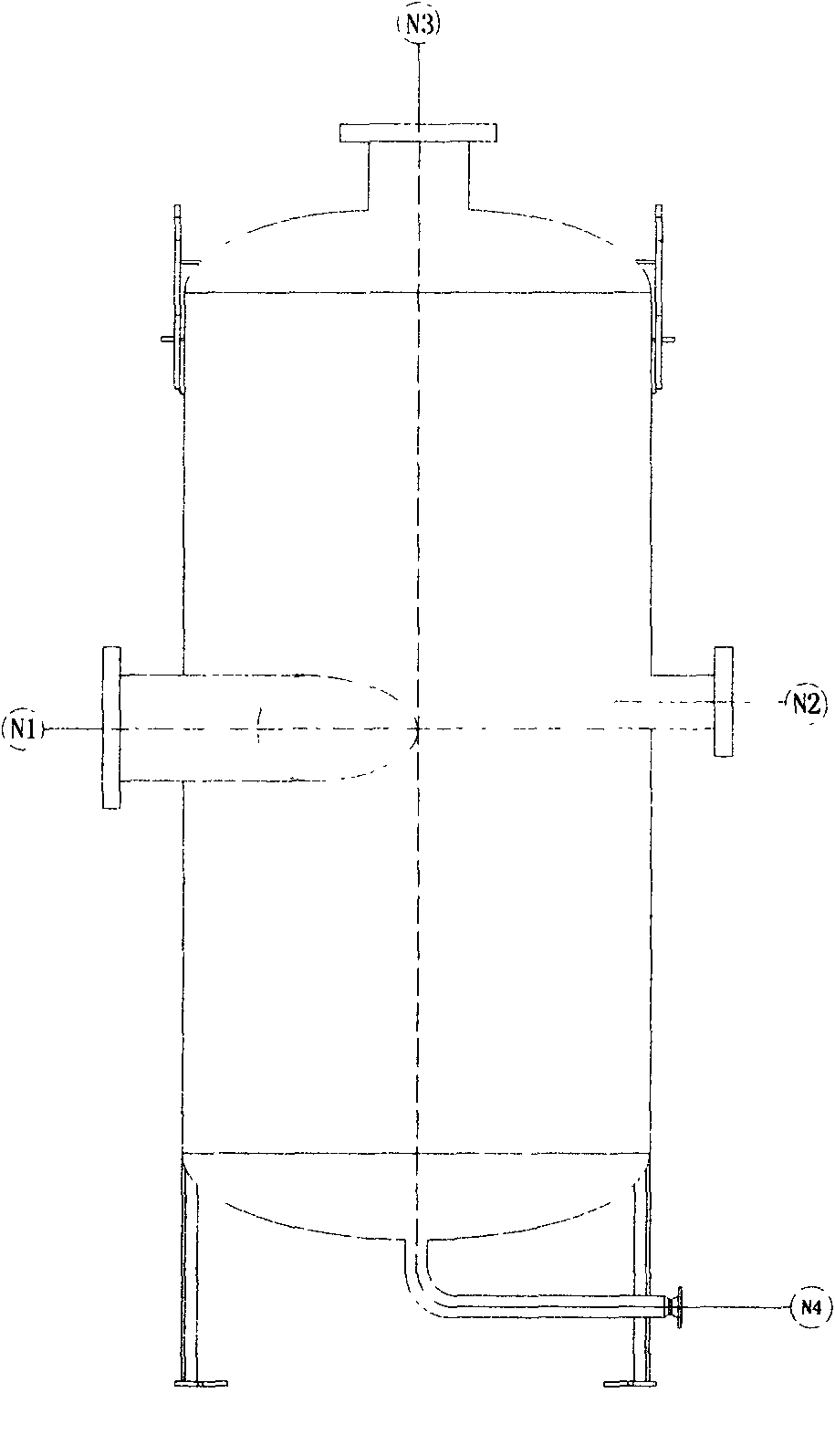

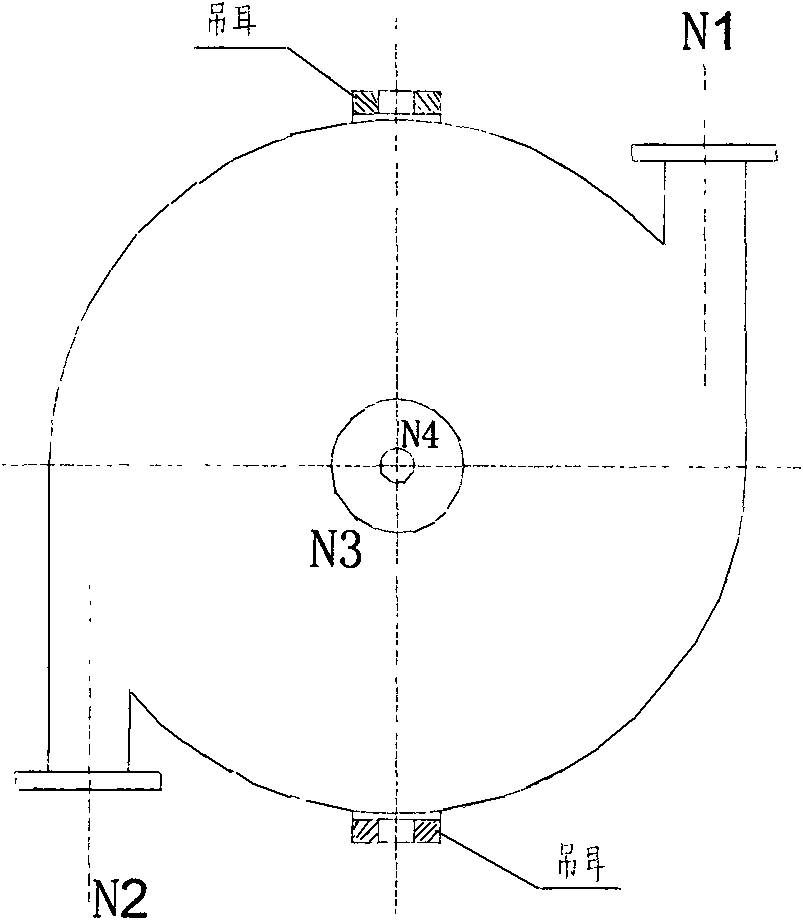

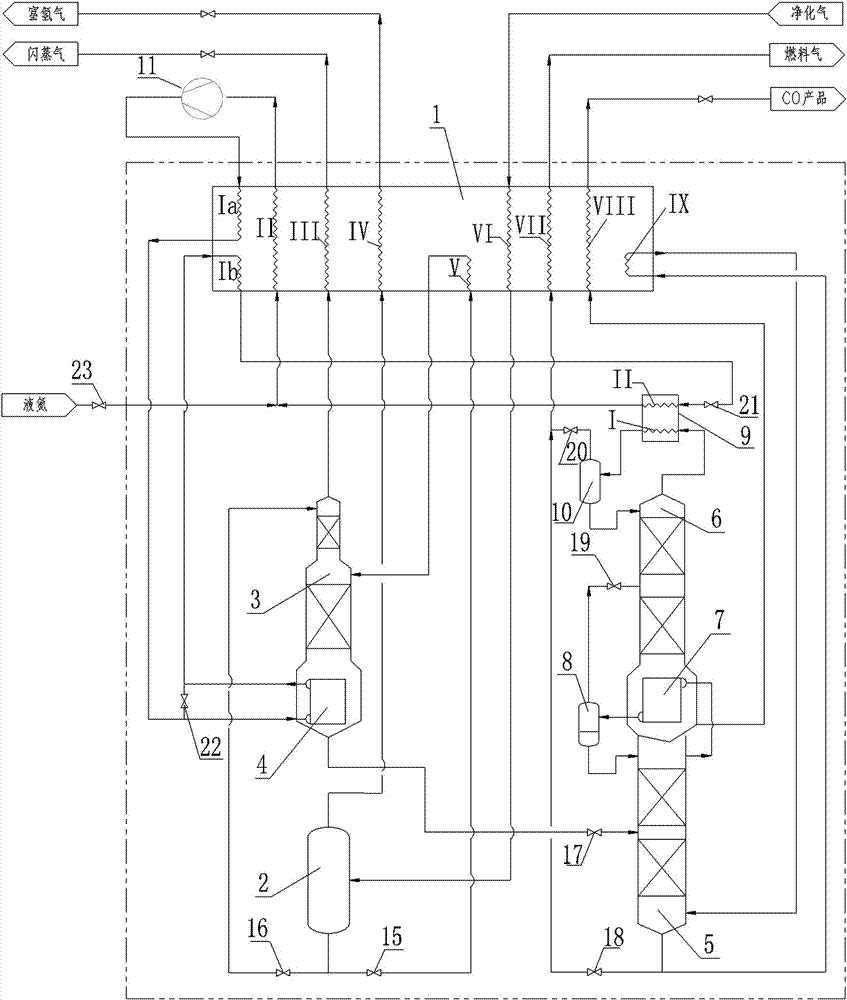

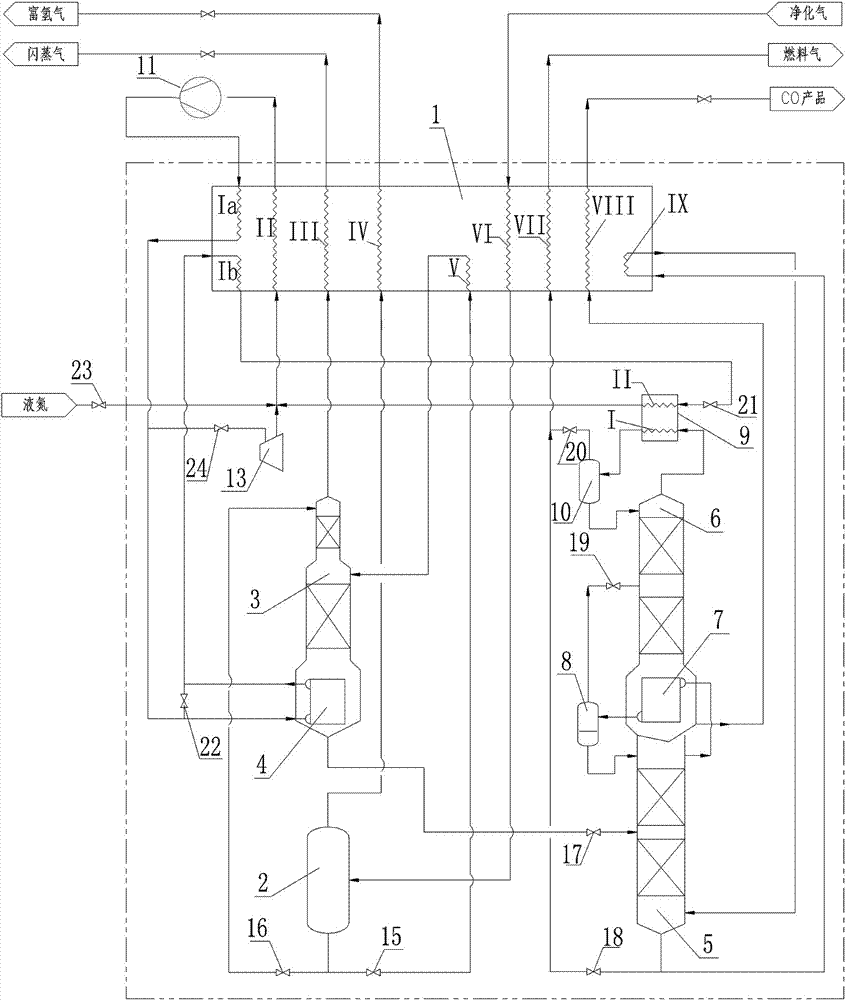

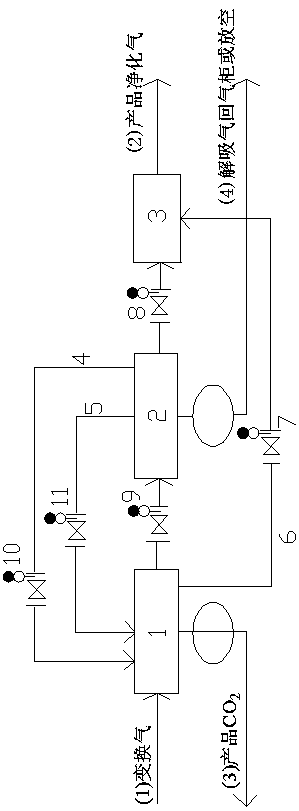

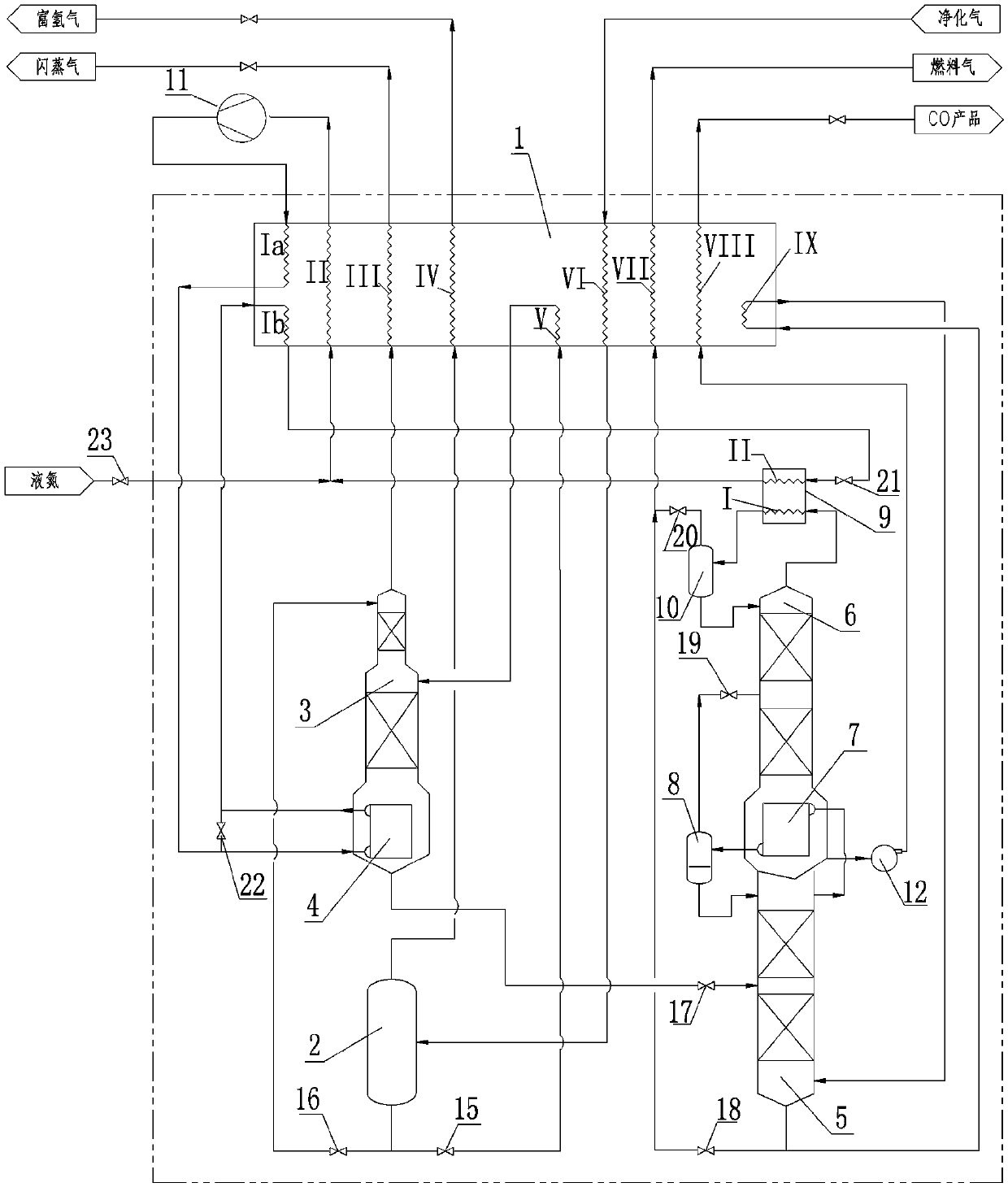

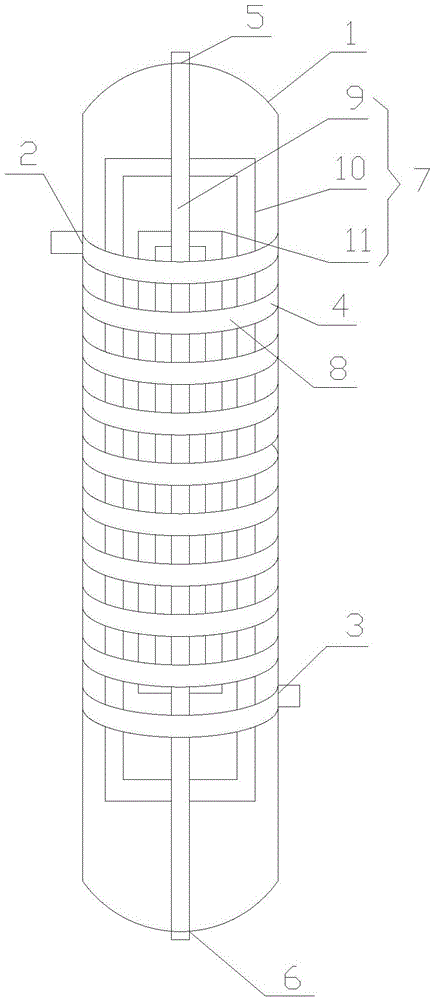

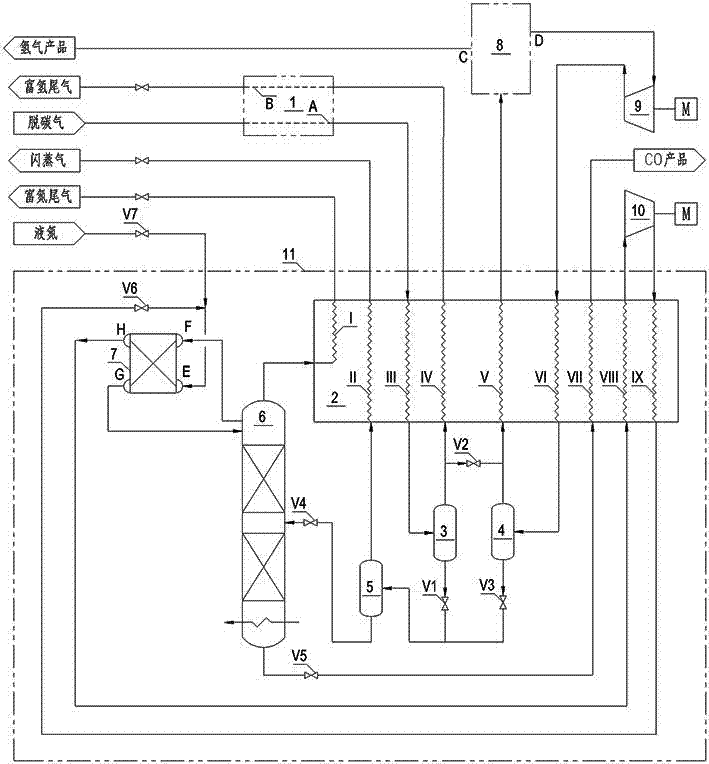

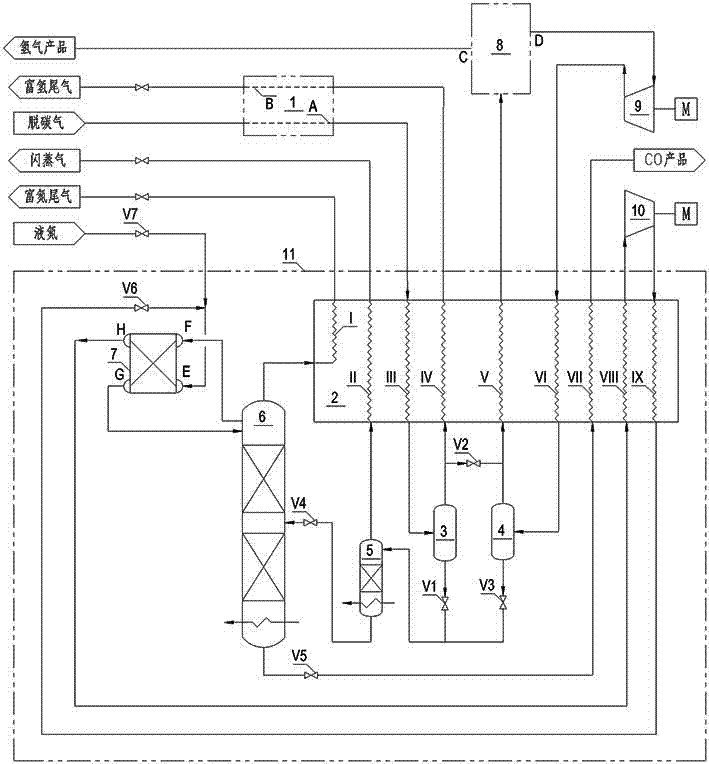

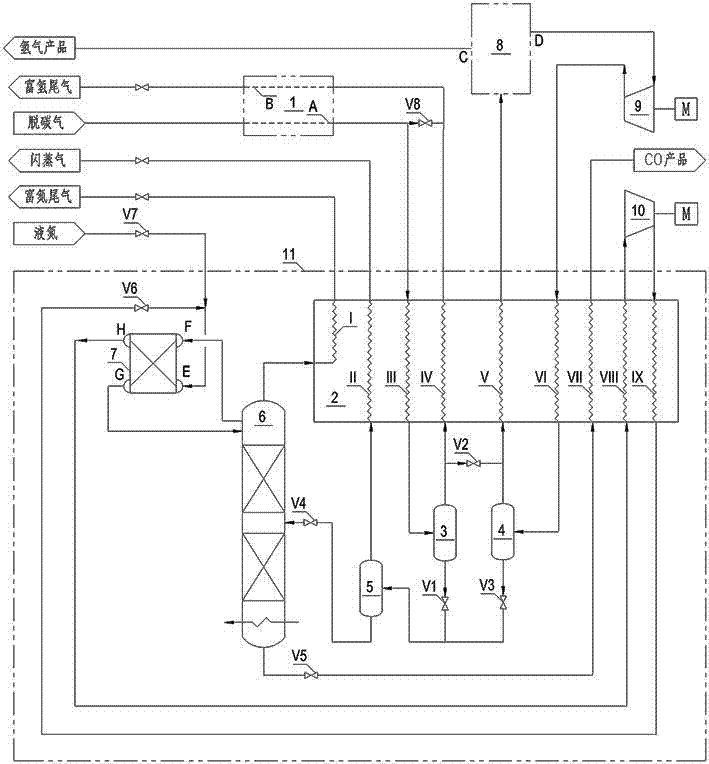

Nitrogen-cycled methane washing system and method for separating CO and H2 in deep cooling manner

ActiveCN107367127AHigh recovery rateGive full play to high efficiencySolidificationLiquefactionNitrogen cycleDehydrogenation

The invention discloses a nitrogen-cycled methane washing system for separating CO and H2 in a deep cooling manner. The nitrogen-cycled methane washing system comprises a main heat exchanger, a methane washing tower, a hydrogen gas extraction tower, a demethanation tower, a denitrification tower, a condensation evaporator, a methane liquid pump, a cycled-nitrogen compressor and a CO product compressor. The invention further discloses a nitrogen-cycled methane washing method for separating the CO and H2 in the deep cooling manner. The method comprises the steps of heat exchange, methane washing, dehydrogenation, demethanation, denitrification, nitrogen gas compression and refrigeration cycle, CO product compression and the like. The nitrogen-cycled methane washing system and method have the beneficial effects that the methane washing method is adopted to produce the H2, the energy consumption and investment for producing the H2 are greatly lowered, and the recycling rate of the CO and the H2 can also be increased; the nitrogen cycle compression and refrigeration process is adopted, and high efficiency and low investment of a nitrogen compressor are fully played; the condensation evaporator is arranged, the demethanation tower and the denitrification tower are integrally connected ingeniously, and rectification energy consumption is greatly lowered; the start and purification time of a device can also be shortened, and the venting amount in the start stage is reduced; and good economic benefits and environmentally-friendly benefits are achieved.

Owner:四川蜀道装备科技股份有限公司

Low-pressure natural gas recovering system for offshore gas field

The invention discloses a low-pressure natural gas recovering system for an offshore gas field. In the low-pressure natural gas recovering system for the offshore gas field, a gas phase outlet of a high-pressure oil-gas-water separator is communicated with a dry gas compressor, an oil phase outlet of the high-pressure oil-gas-water separator is communicated with a low-pressure oil-gas-water separator, a gas phase outlet of the low-pressure oil-gas-water separator is respectively communicated with a fuel system and a wet gas compressor, and an oil phase outlet of the low-pressure oil-gas-water separator is communicated with a condensate oil buffer tank; a material flow from a low-pressure well mouth of the gas field at sea is input into the low-pressure oil-gas-water separator or the condensate oil buffer tank; the gas phase outlet of the condensate oil buffer tank is sequentially communicated with a low-pressure gas cooler, a low-pressure gas hydrocyclone, a low-pressure gas booster compressor and a low-pressure gas aftercooler. The low-pressure natural gas recovering system for the offshore gas field is mainly used for recovering and using natural gas, which is low in pressure or micro in positive pressure or small in flow quantity, in the gas filed at sea, so that the emptying quantity of the gas field is reduced, and energy conservation and emission reduction are achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

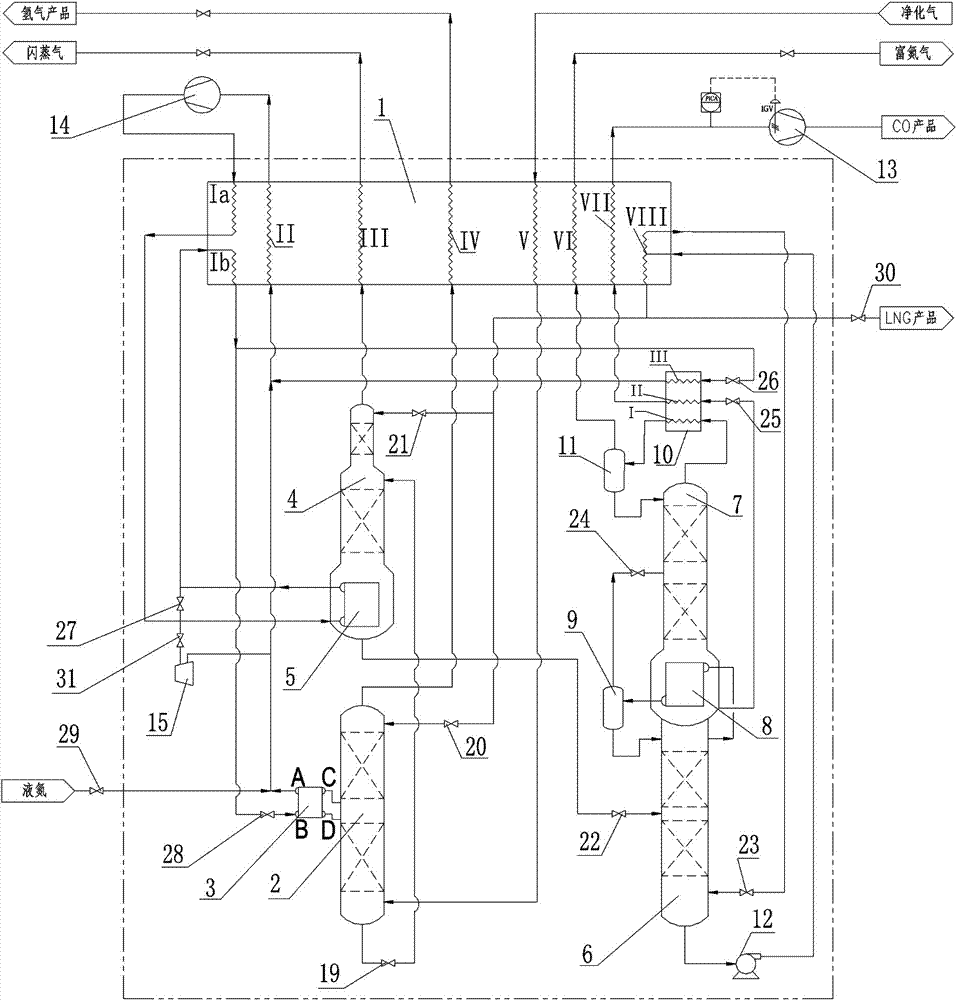

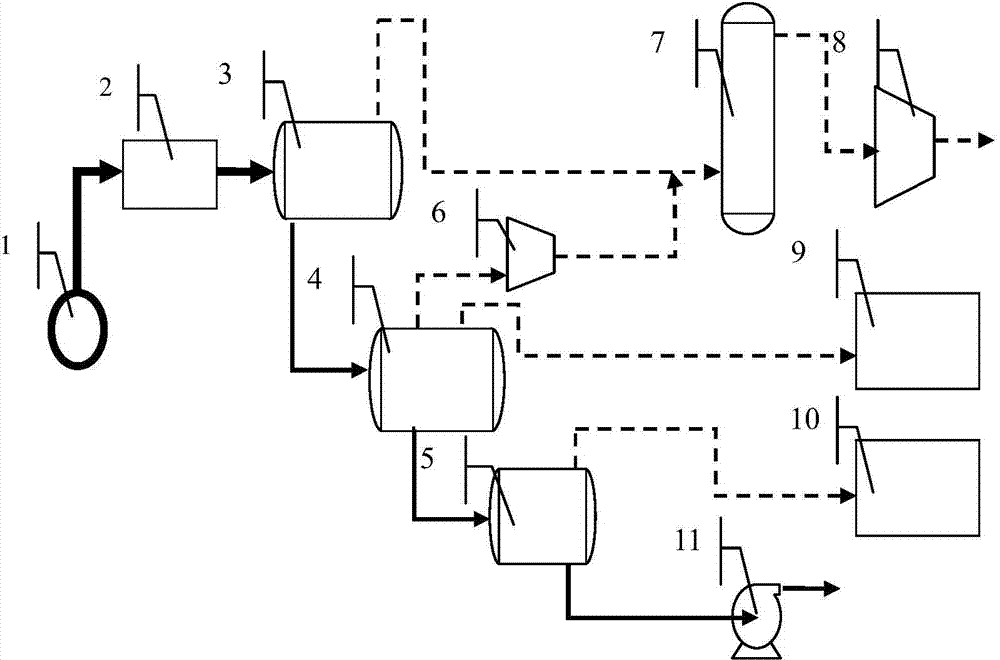

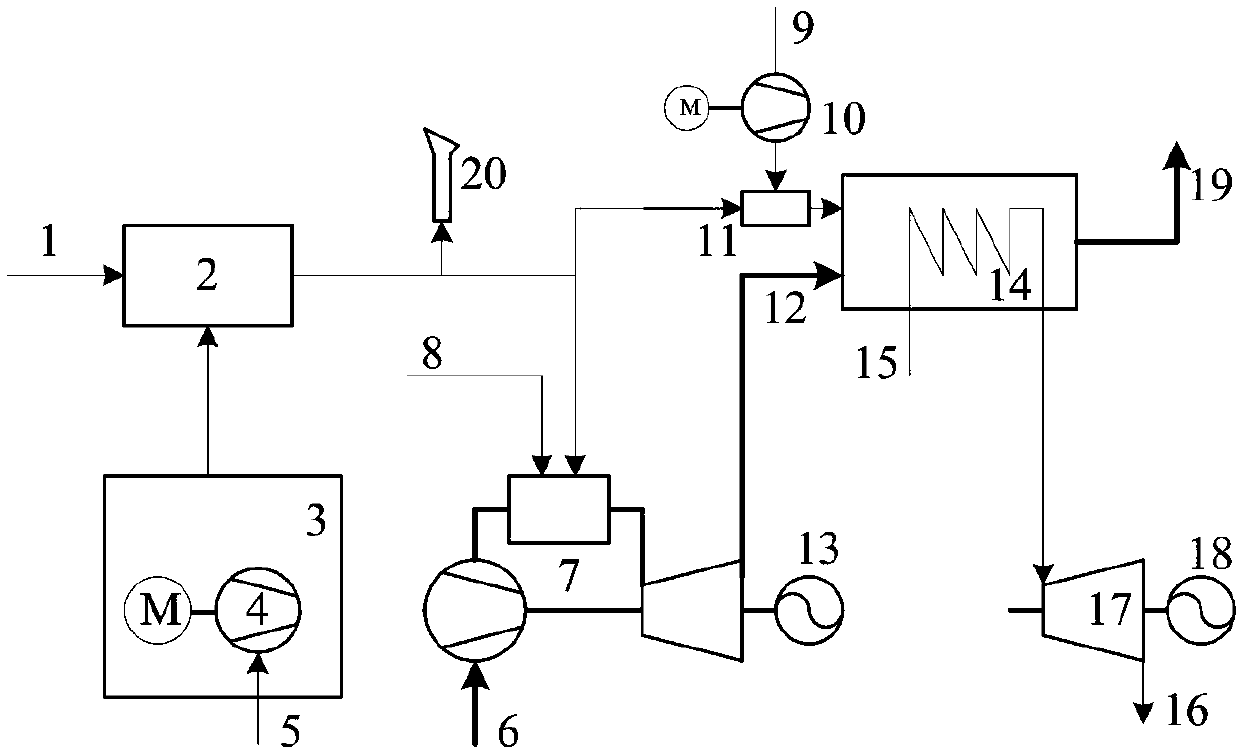

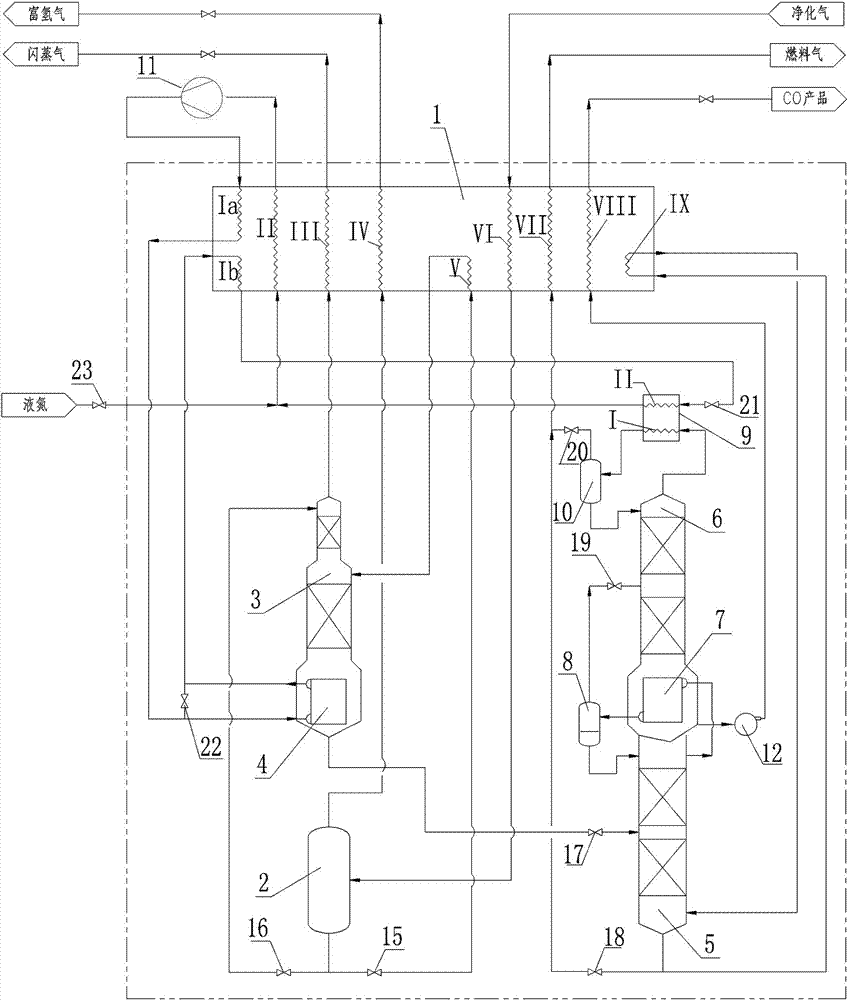

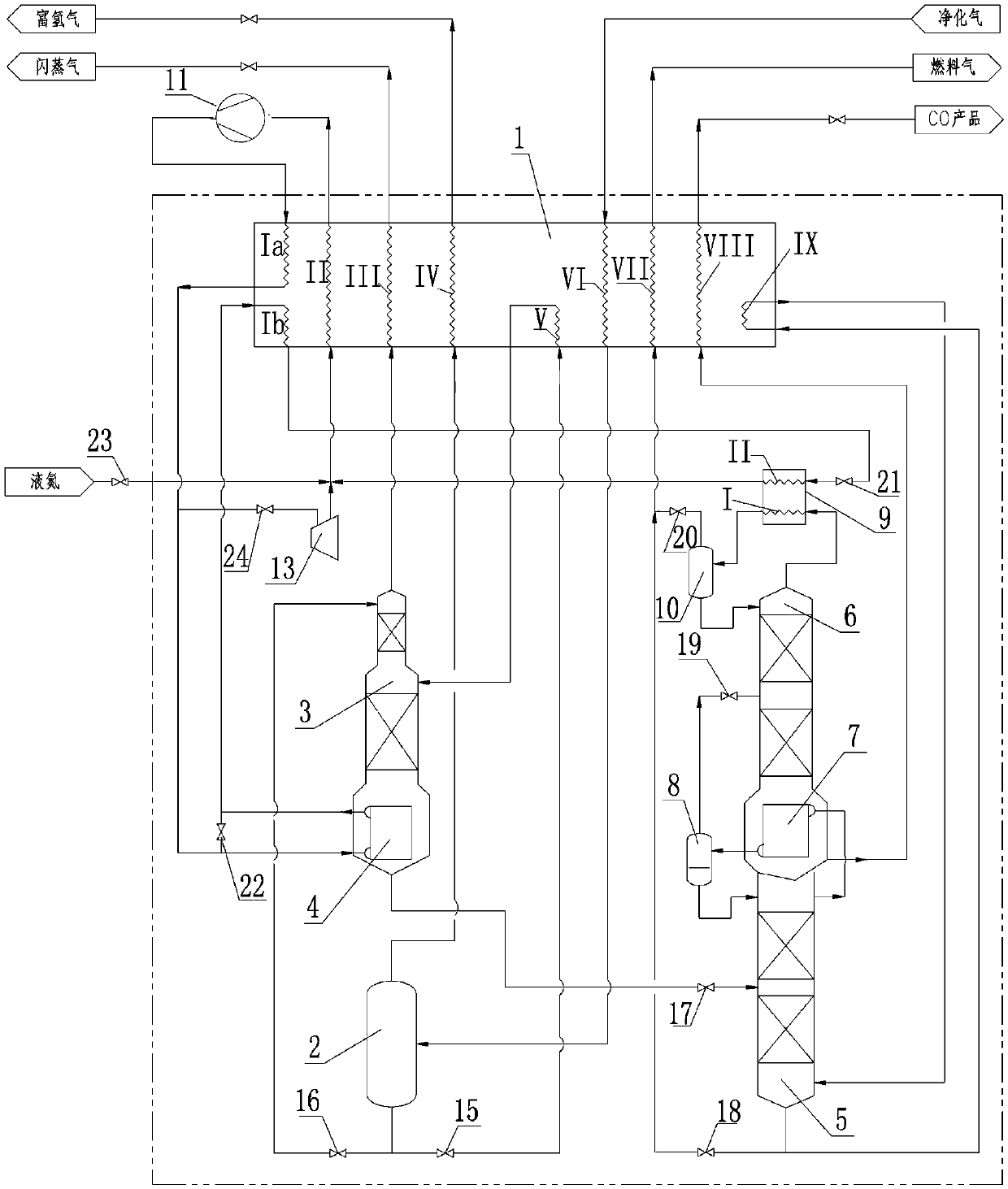

CO cryogenic separation system using double circulation and separation method thereof

ActiveCN107328166AReduce distillation energy consumptionReduce energy consumptionSolidificationLiquefactionGas compressorNitrogen cycle

The invention discloses a CO cryogenic separation system using double circulation. The CO cryogenic separation system comprises main heat exchangers, a low-temperature separator, a hydrogen stripping tower, a denitriding tower, a demethanizer, a CO compressor and a circulation nitrogen compressor. The invention further discloses a separation method of the CO cryogenic separation system using double circulation. The method includes the processing steps of heat transfer, dehydrogenation, denitrification, demethanation, CO compression cycle, nitrogen compression refrigeration cycle and the like. The CO cryogenic separation system using double circulation and the separation method thereof have the beneficial effects that the double-circulation process of CO compression and nitrogen compression is adopted, and the dual advantages that rectification energy consumption of CO compression cycle is low and compression energy consumption and investment of nitrogen cycle are low are given into play. A heat source of a rectifying tower evaporator and a cold source of a condenser are optimized, and rectification loads can be controlled reliably and stably. Starting and purifying time of the device can further be shortened, and the evacuation amount at the starting stage is decreased. Energy consumption is low, the starting speed is high, the investment can be reduced, and the quantity of emissions is small. The general trend of energy saving and cost reduction are met, and the economic benefits and environmental protection benefits are good.

Owner:四川蜀道装备科技股份有限公司

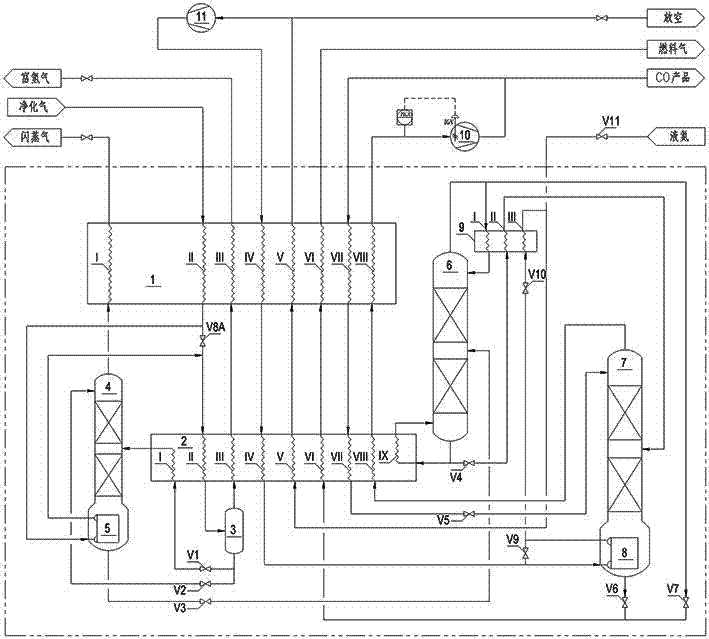

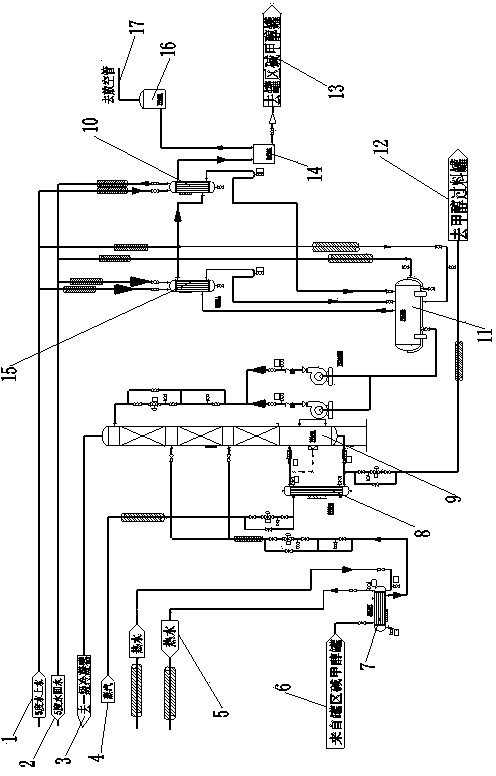

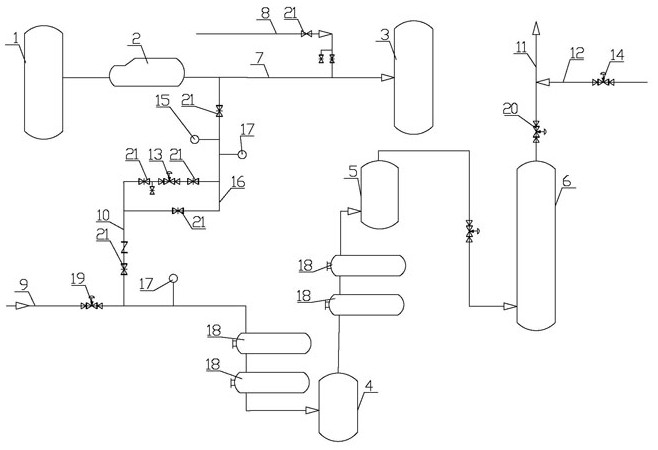

Pulverized coal preparation system and method

ActiveCN107166421AReduce ventingLess investmentLump/pulverulent fuel preparationGas heaterEngineering

The invention provides a pulverized coal preparation system and method. The pulverized coal preparation method comprises a coal pulverizer, a coal pulverizer circulating gas heater, a pulverized coal collector, a pulverized coal storage bin and a circulating fan, wherein the coal pulverizer is provided with a pulverized coal inlet, a circulating gas inlet and a circulating gas outlet; the circulating gas outlet is connected to a material inlet of the pulverized coal collector, and a solid outlet of the pulverized coal collector is connected with the pulverized coal storage bin; a gas outlet of the pulverized coal collector is connected with a gas inlet of the fan, and a gas outlet of the fan is connected with a gas inlet of the heater; a gas outlet pipeline of the heater is divided into two branches, one branch is connected with the circulating gas inlet of the coal pulverizer, and the other branch is connected to a pipeline between the coal pulverizer and the pulverized coal collector; and a safety emptying pipeline, an inert gas supply pipeline and a compressed air supply pipeline are connected to a connection pipeline between the fan and the heater. By adoption of the system, qualified pulverized coal can be prepared under energy-saving, safe and clean conditions.

Owner:BEIJING PETROCHEM ENG

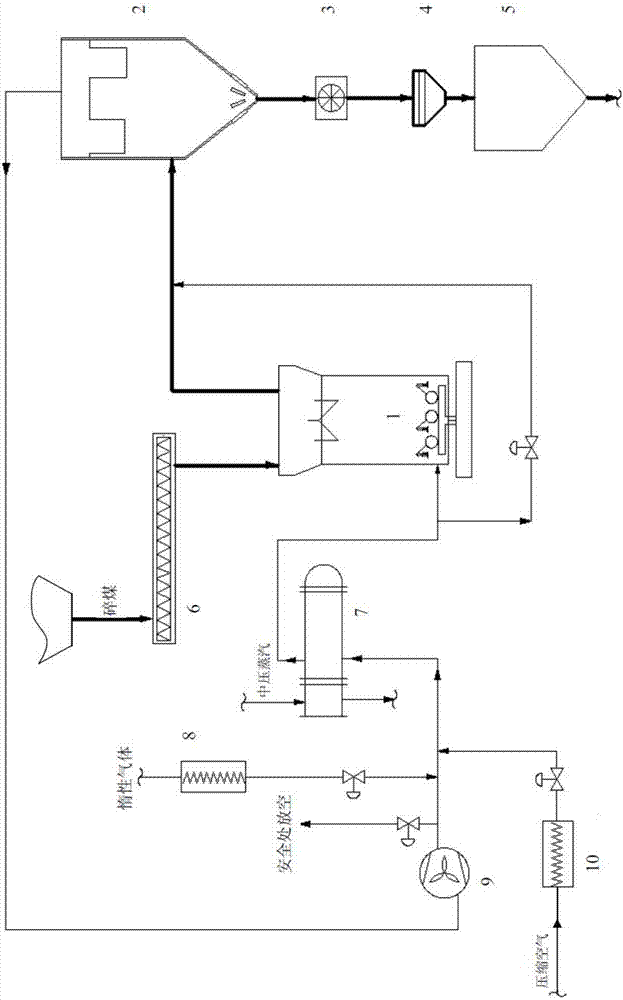

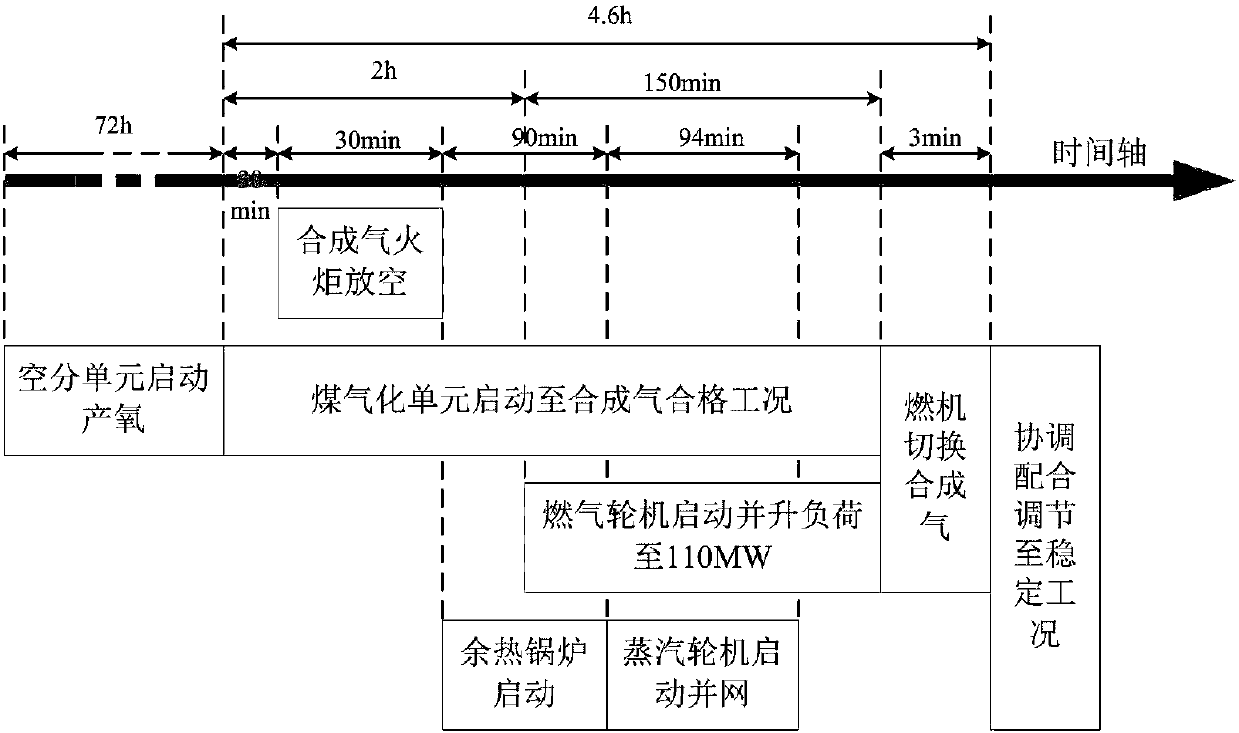

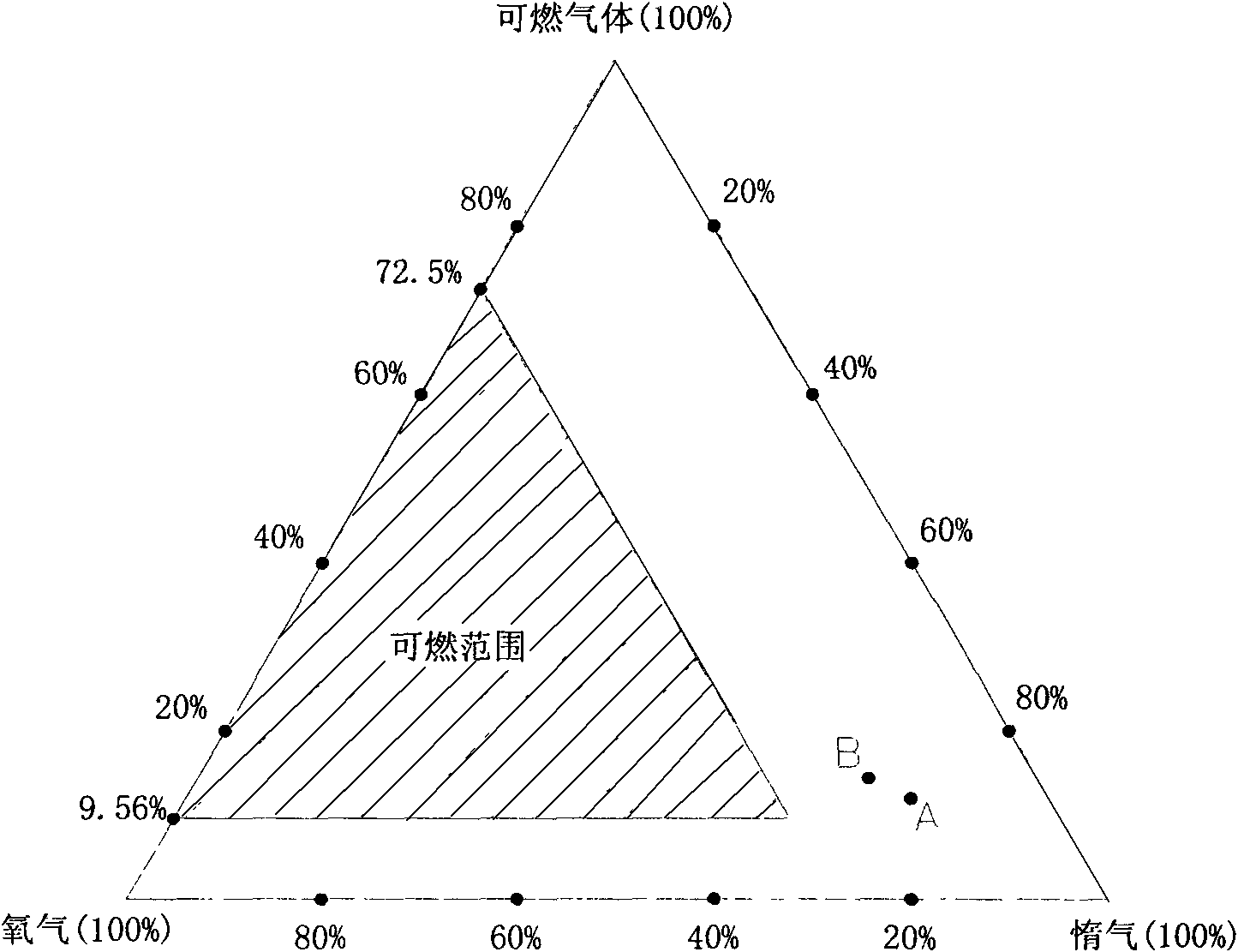

Energy-saving start system of IGCC power station

PendingCN107664046AReduce startup timeReduce electricity purchaseGas turbine plantsSteam engine plantsAutomotive engineeringGas turbines

An energy-saving start system of an IGCC power station is composed of a coal gasification unit, an air separating unit, a gas turbine, a gas turbine generator, an afterburning fan, an afterburner, a waste heat boiler, a turbine, a turbonator and a flare tower. When the power station is started, the air separating unit and the coal gasification unit are started first, synthesis gas generated by thecoal gasification unit is conveyed to the afterburner to start the waste heat boiler and the turbine power generating system, and until the gas turbine is started and synthesis gas fuel is switched,afterburner stops running; the sequence limit that the waste heat boiler and the turbine must wait for first start of the gas turbine in the conventional start process is eliminated, the turbine can be started before the gas turbine, the start time of the whole plant is shortened, the links of waiting for turbine heating, impulse starting and grid-connection in the loading-up process after gas turbine ignition are omitted, load-up and fuel switching can be conducted on the gas turbine fast, and the energy-saving effect is remarkable.

Owner:CHINA HUANENG GRP CO LTD +1

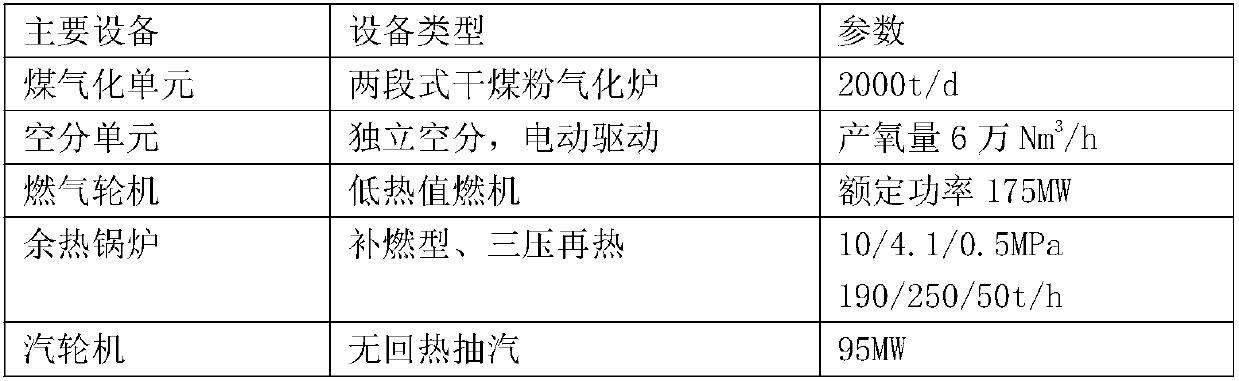

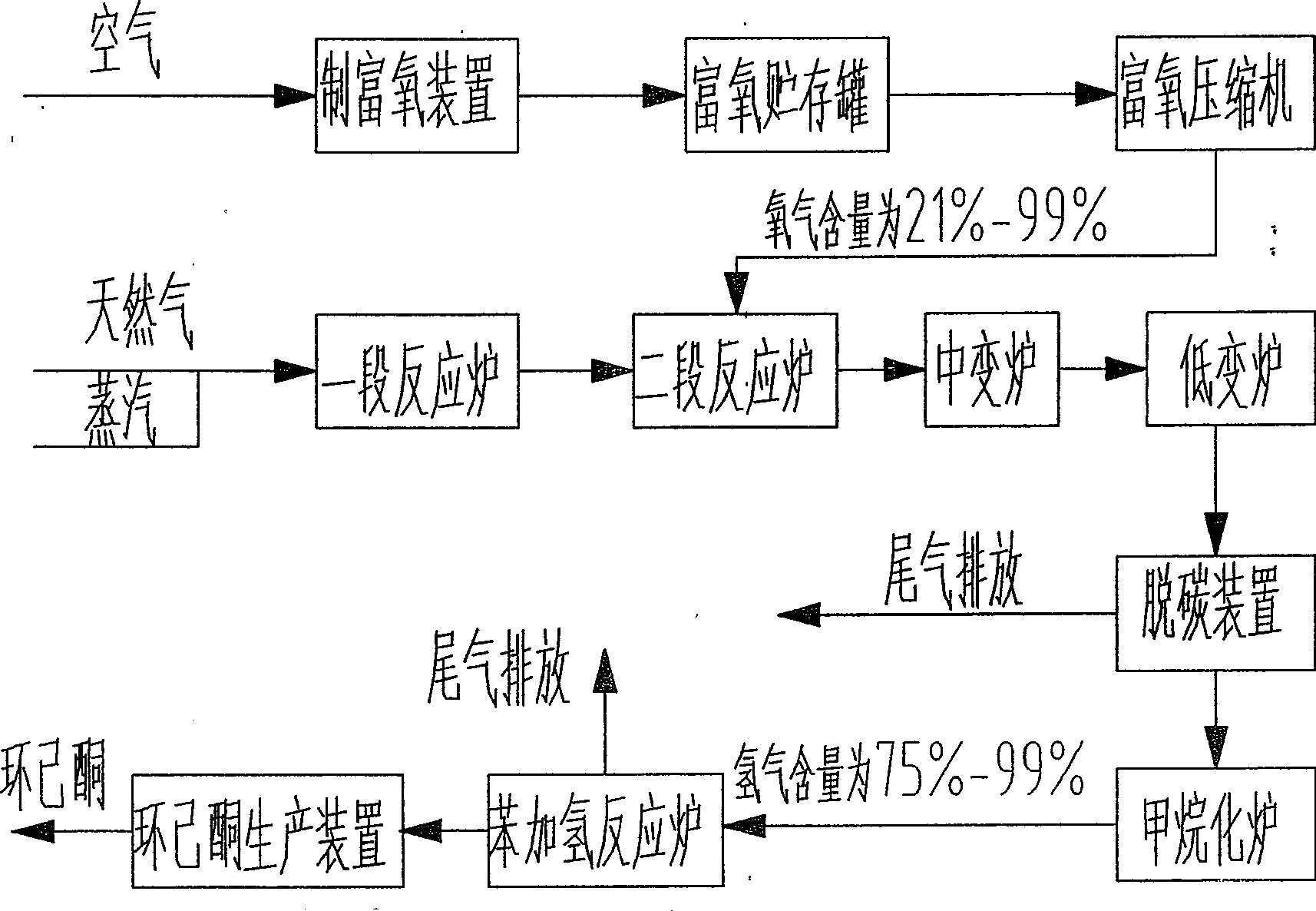

Technique for preparing cyclohexane by benzene hydrogenation using hydrogen produced by oxygen enrichment natural gas steam reforming method

InactiveCN101417918AEmission reductionReduce shortingHydrogenHydrocarbon by hydrogenationSteam reformingMethanation

The invention relates to a technique method for using hydrogen obtained from rich oxygen in a natural gas steam reforming method to prepare cyclohexane with benzene hydrogenation, in particular to be used in the raw material hydrogen which is needed in the cyclohexane production technique. The rich oxygen produced in a rich oxygen device and the reforming gas obtained from a natural gas steam reforming method in a primary reformer are reacted in a secondary reformer; and then the steps of medium and low change, decarburization and methanation to prepare hydrogen with high hydrogen content which is used for producing cyclohexane, thereby reducing the hydrogenation exhaust emissions. The devices for realizing the treatment method comprises a rich oxygen production device, a rich oxygen condensing machine, rich oxygen content controlling system, natural gas steam primary reformer, a secondary reformer, a middle and low furnace, a decarbuation device, a methanation furnace and a benzene hydrogenation furnace. The invention has the advantages of replacing air with rich oxygen, reducing the content of nitrogen in the hydrogen production process and the tail gas discharging amount in the benzene hydrogenation process, increasing the hydrogen content in the hydrogen production process; the hydrogen is used in the benzene hydrogenation process, thereby achieving the purpose of energy saving, discharge reduction and environmental protection.

Owner:HONGYE CHEM GRP

Dehydrogenation method of carbon dioxide feed gas

The invention discloses a dehydrogenation method of carbon dioxide feed gas. The method comprises the following steps: 1) injecting oxygen-enriched air in the carbon dioxide feed gas to ensure the content of oxygen to be 1.25-1.4%; 2) injecting the carbon dioxide feed gas containing oxygen-enriched air into a compression engine to compress, performing fine desulfurization, performing heat transferto the desulphurized gas, heating, sending the obtained gas to a dehydrogenation reactor to dehydrogenize to ensure the content of hydrogen and other combustible gases in the dehydrogenized carbon dioxide gas to be less than 50PPm; 3) performing heat transfer to the dehydrogenized gas, cooling, then sending the obtained gas to a CO2 vapour liquid separator to perform gas water separations and finally emptying liquid drops to obtain the gas which is used for the synthesis of urea. The dehydrogenation method of carbon dioxide feed gas adds oxygen to perform dehydrogenation and adds air to perform anticorrosion so as to avoid the problem that a great deal of nitrogen and other inert gases are generated after the dehydrogenation step, reduce the venting amount of the high pressure system, increase the conversion rate, improve the system loading, increase the urea capacity, reduce the absorption loading, desorption loading and hydrolysis loading, lower the consumption of ammonia, steam andthe like and benefit the environmental control.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

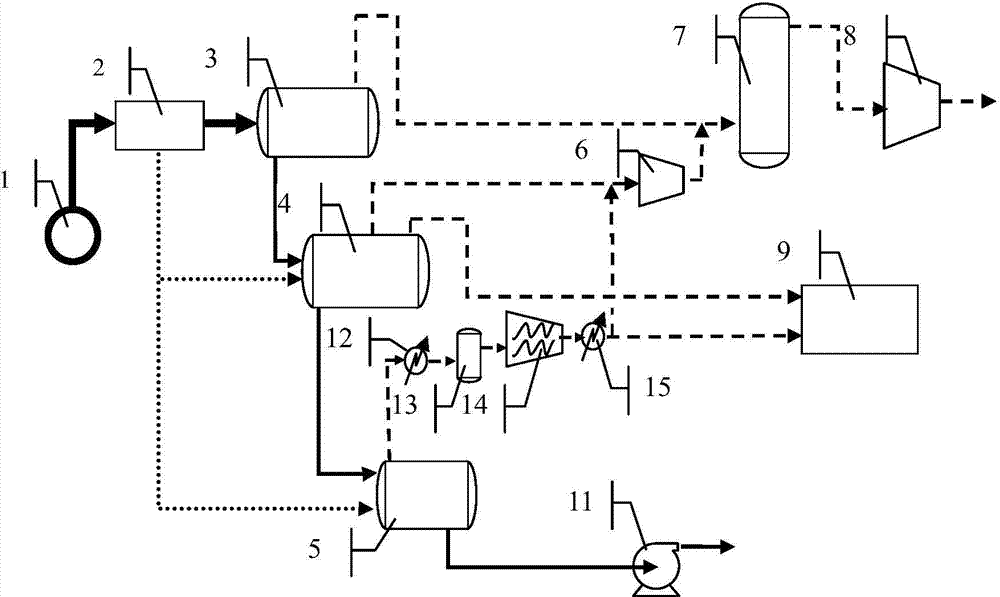

CO cryogenic separation system and method using nitrogen cycle

ActiveCN107473223AImprove efficiencyMeet pressure requirementsHydrogen separationCarbon monoxideNitrogen cycleDistillation

The invention discloses a CO cryogenic separation system using nitrogen cycle. The CO cryogenic separation system comprises a main heat exchanger, a cryogenic separator, a hydrogen stripper, a demethanizer, a denitrogenation tower, a condensing evaporator and a cycle nitrogen compressor. The invention further discloses a CO cryogenic separation method using nitrogen cycle, wherein the CO cryogenic separation method comprises process steps of heat exchange, dehydrogenation, demethanation, denitrogenation, nitrogen compression refrigeration cycle and the like. The CO cryogenic separation system and method provided by the invention have beneficial effects that a nitrogen cycle compression and refrigeration process is adopted to fully play roles of high efficiency and low investment of a nitrogen compressor; the condensing evaporator is arranged to cleverly integrate the demethanizer and the denitrogenation tower, so as to greatly reduce power consumption of distillation; an operation pressure of a distillation tower is increased or a CO liquid pump is provided for replacing a CO compressor so as to meet pressure requirements of CO products; start-up and purification time of the device can be shortened and a venting amount at a start-up stage can be reduced; the system and the method has advantages of low energy consumption, fast start-up, investment saving and less emission, are in line with a general trend of energy conservation and consumption reduction, and have good economic and environmental protection benefits.

Owner:四川蜀道装备科技股份有限公司

Method for carrying out tail gas treatment by using methylal tail gas condenser

InactiveCN104069715AReduce the temperatureInitial total dropOrganic chemistryOrganic compound preparationActivated carbonProcess engineering

The invention discloses a method for carrying out tail gas treatment by using a methylal tail gas condenser. The method is characterized in that methylal tail gas which is from a tank region alkali methyl alcohol tank passes through a methylal preheater, a methylal rectifying tower, a methylal first-class tail gas condenser, a methylal second-class tail gas condenser as well as a liquid seal groove and an active carbon tank sequentially, and methylal, methanol and methyl alcohol in the methylal tail gas are recycled. The method provided by the invention has the advantages that discharging volume is greatly reduced through a perfect methylal tail gas processing device and a perfect methylal tail gas processing method, methylal recovery is improved, and the environment protection pressure is reduced.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

Variable-pressure adsorption method using auxiliary system

A pressure-variable adsorption process with auxiliary system features use of a primary adsorption-regeneration cyclic system composed of two or more adsorption towers and an additional adsorption-regeneration cyclic system also composed of two or more adsorption towers. The charge gas is input to the said primary system which outputs the components difficult to be adsorbed. When the content of the components easily adsorbed in the primary system is going to go beyond the standard value, its output is switched to the said additional system. It can simulatenious obtain high-purity easily adsorbed components and difficultly adsorbed components with high output rate and low cost.

Owner:王玉

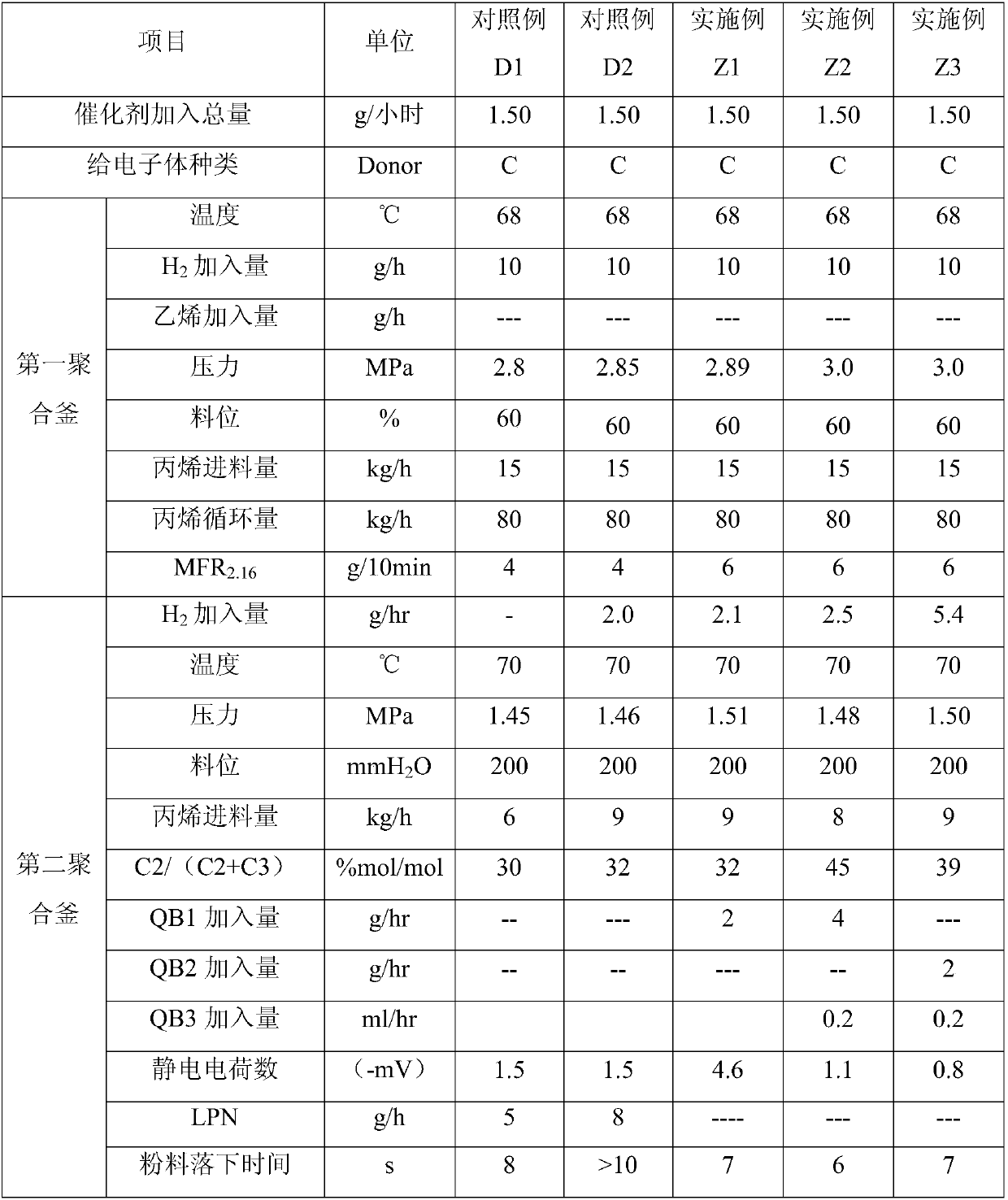

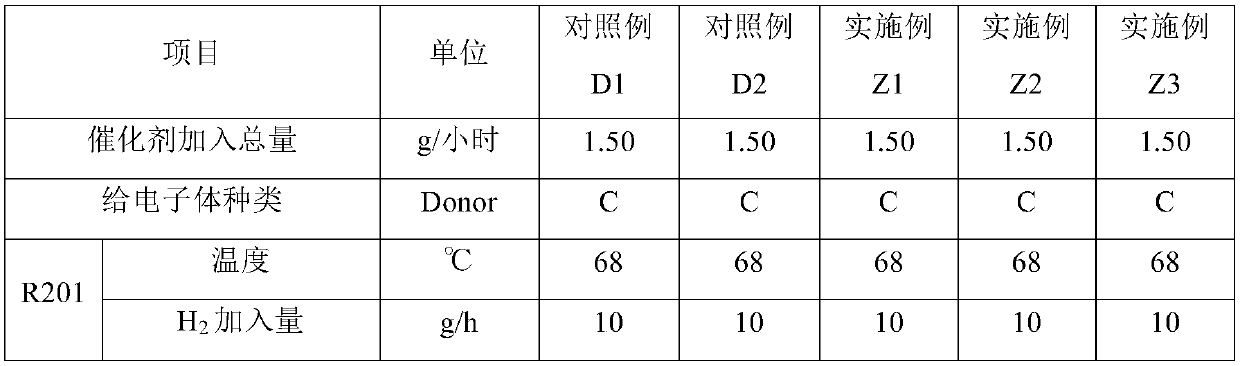

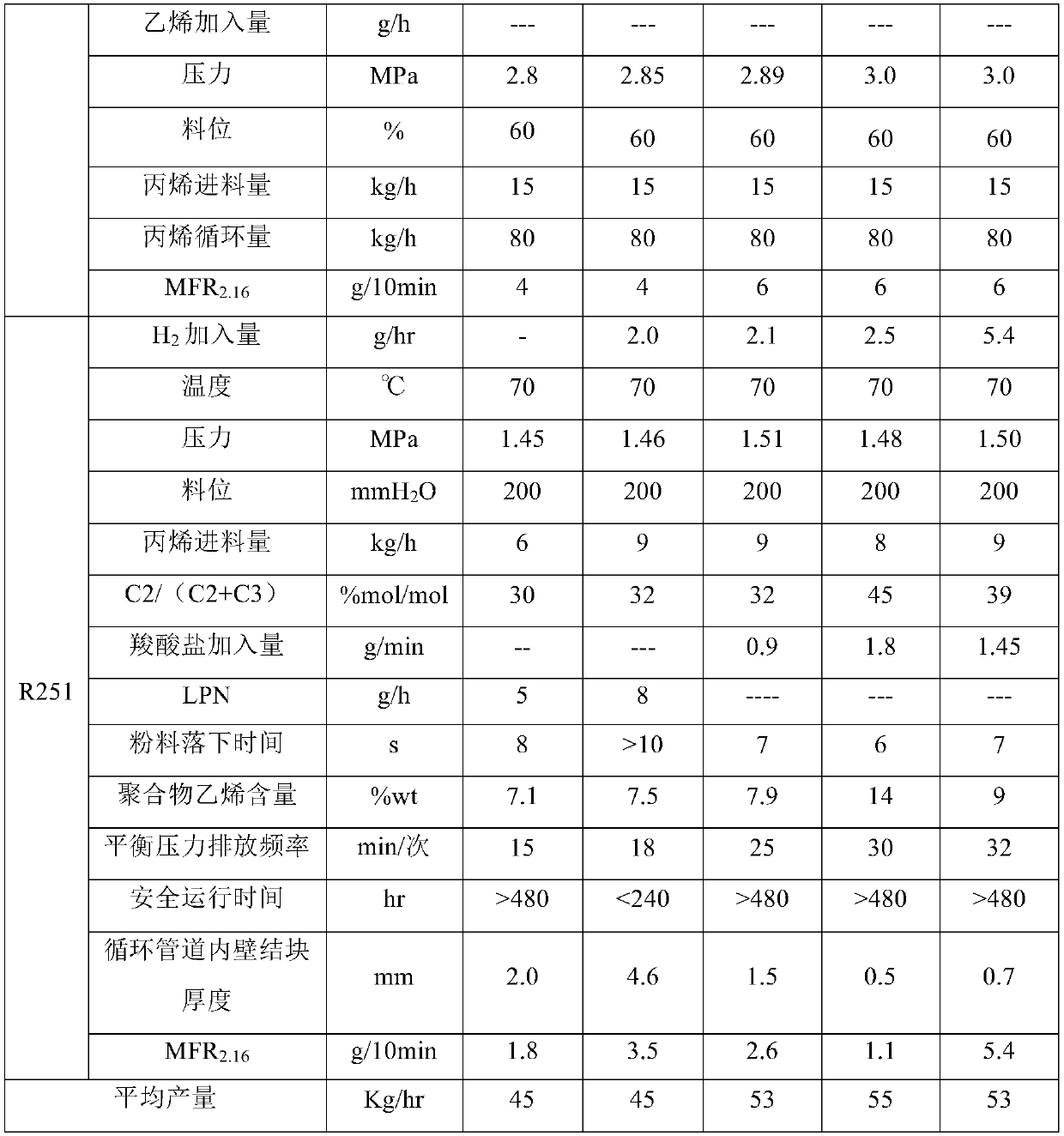

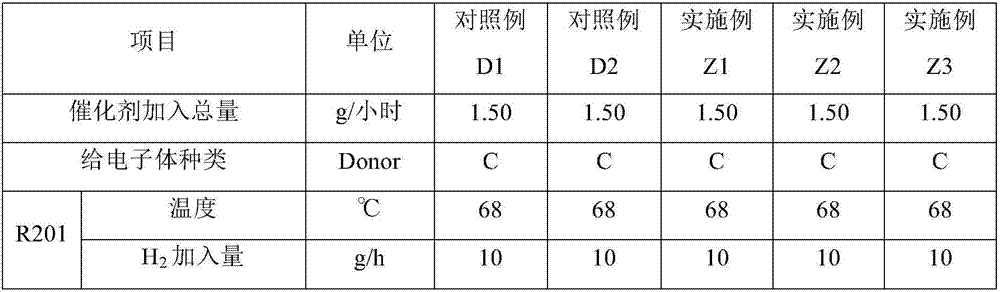

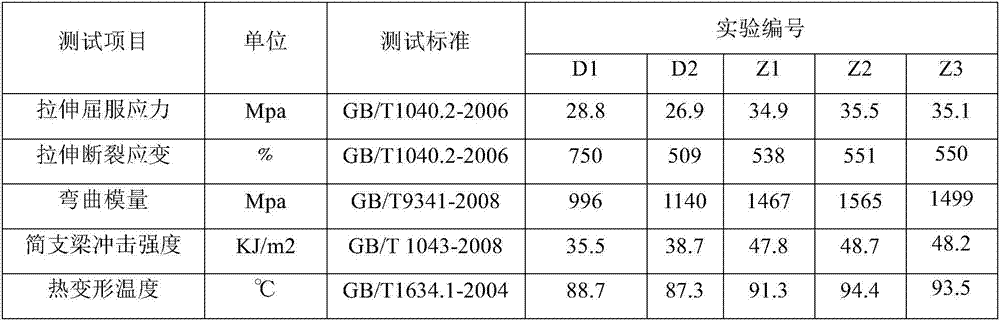

Method for producing copolymerized polypropylene by using propylene gas phase polymerization device

The invention discloses a method for producing copolymerized polypropylene by using a propylene gas phase polymerization device, wherein a sticking inhibitor is added during the polymerization, and isa refined organic compound. According to the present invention, LPN is replaced with the refined organic compound, such that the component of the inert gas in the reactor can be reduced, the ventingamount can be reduced, the polymerization efficiency of the catalyst can be improved, the smooth operation of the device can be achieved, and the ethylene-propylene impact-resistant product with highethylene content can be obtained; and the sticking probability of the ethylene-propylene copolymer can be reduced after the organic particles are added while the organic particles and the kettle wallare subjected to collision friction to form static electricity, and the alcohol-based substance enters the reaction kettle after being atomized or vaporized through the power of the fan, and can neutralize the static electricity, such that the polymerization can be stably performed for a long time.

Owner:SINOPEC YANGZI PETROCHEM +1

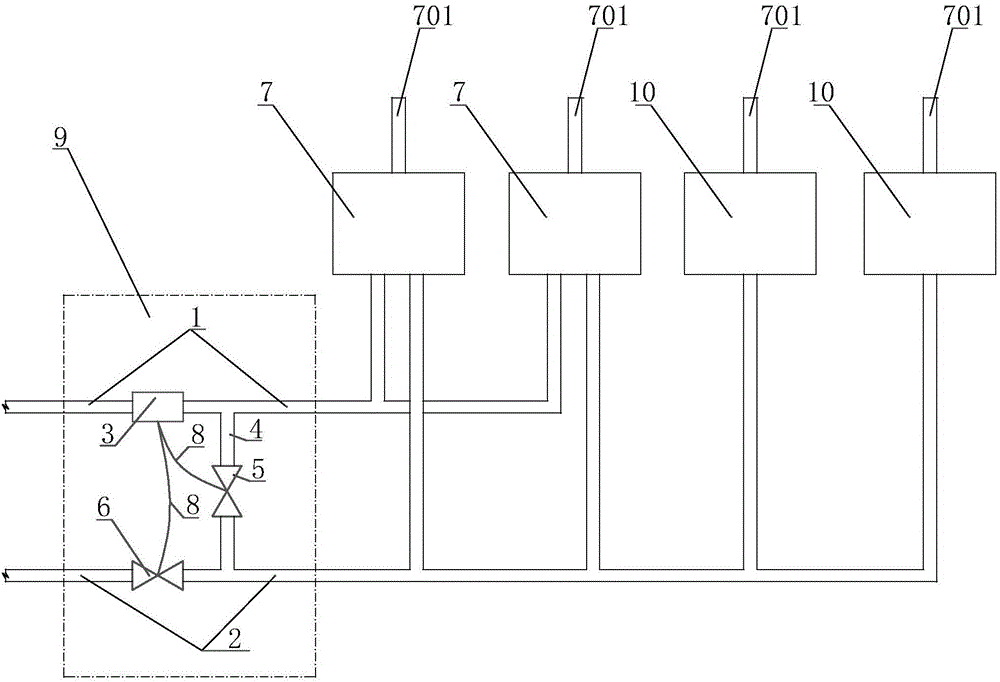

Cold water and hot water supply device and cold water and hot water supply system

ActiveCN105672406AReduce shorting behaviorReduce ventingWater resource protectionOperating means/releasing devices for valvesUser needsEngineering

The invention discloses a cold water and hot water supply device. The cold water and hot water device has the advantages that by fully considering the actual conditions of daily life, the usage amount and frequency of cold water are maximum, the usage amount and frequency of warm water are medium, and the frequency of directly using hot water with higher temperature is minimum, so that when the cold water or warm water is used, the warm water or cold water which is changed from the hot water by temperature lowering in a hot water branch pipe is firstly used; when the hot water is re-filled into the hot water branch pipe, a cold water branch pipe is controlled by a valve to be communicated again, so that the hot water branch pipe is always full of hot water with temperature reaching to setting value after the cold water or warm water is used for multiple times; when a user needs to use hot water, the hot water can be immediately obtained, so that the emptying and waiting are not needed, the emptying behavior is reduced when the hot water branch pipe lacks of hot water, the emptying amount of water resources is reduced, and the waste of water sources is reduced. The invention also discloses a cold water and hot water supply system.

Owner:禹城市瑞诚新能源科技有限公司

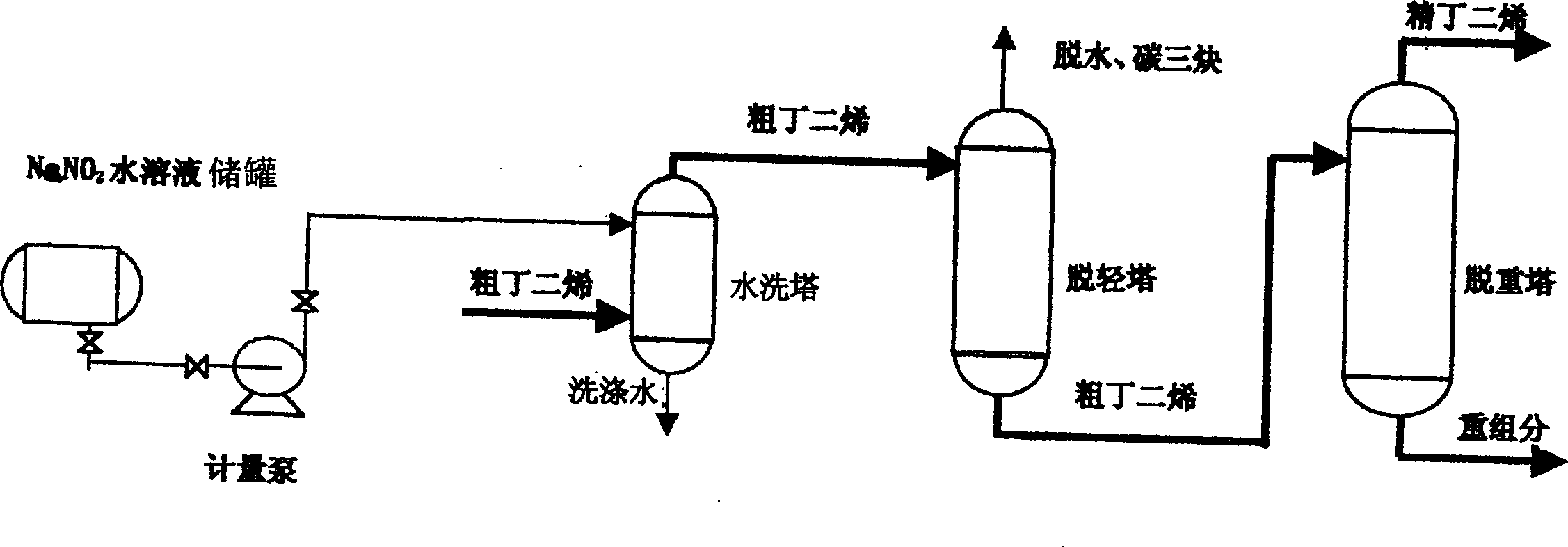

Oxygen removing method of butadiene refining device

InactiveCN1200919CReduce lossesExtended operating cycleHydrocarbon purification/separationHydrocarbonsOxygenAqueous solution

The deoxygenation method of the butadiene refining unit is to add a deoxygenation system before the crude butadiene raw material enters the water washing tower, and a certain concentration of NaNO 2 The aqueous solution is continuously pumped into the washing tower with a metering pump to ensure a certain amount of NaNO in the washing tower. 2 Solution concentration, the free oxygen in the raw material is removed by the sufficient contact between the washing water and the material in the water washing tower. NaNO in washing tower 2 The concentration of the solution is controlled so that the aqueous solution can effectively remove the oxygen in the raw material without causing pollution to the subsequent system. The method of the present invention effectively eliminates the oxygen brought into the refining device in the raw material of crude butadiene, and will greatly slow down the formation speed of the terminal polymer in the light removal tower and the weight removal tower, and may gradually disappear, greatly prolonging the operation of the refining device cycle. It will reduce the loss of butadiene caused by venting and deoxygenating the top reflux tank of the original light removal tower.

Owner:CHINA PETROLEUM & CHEM CORP

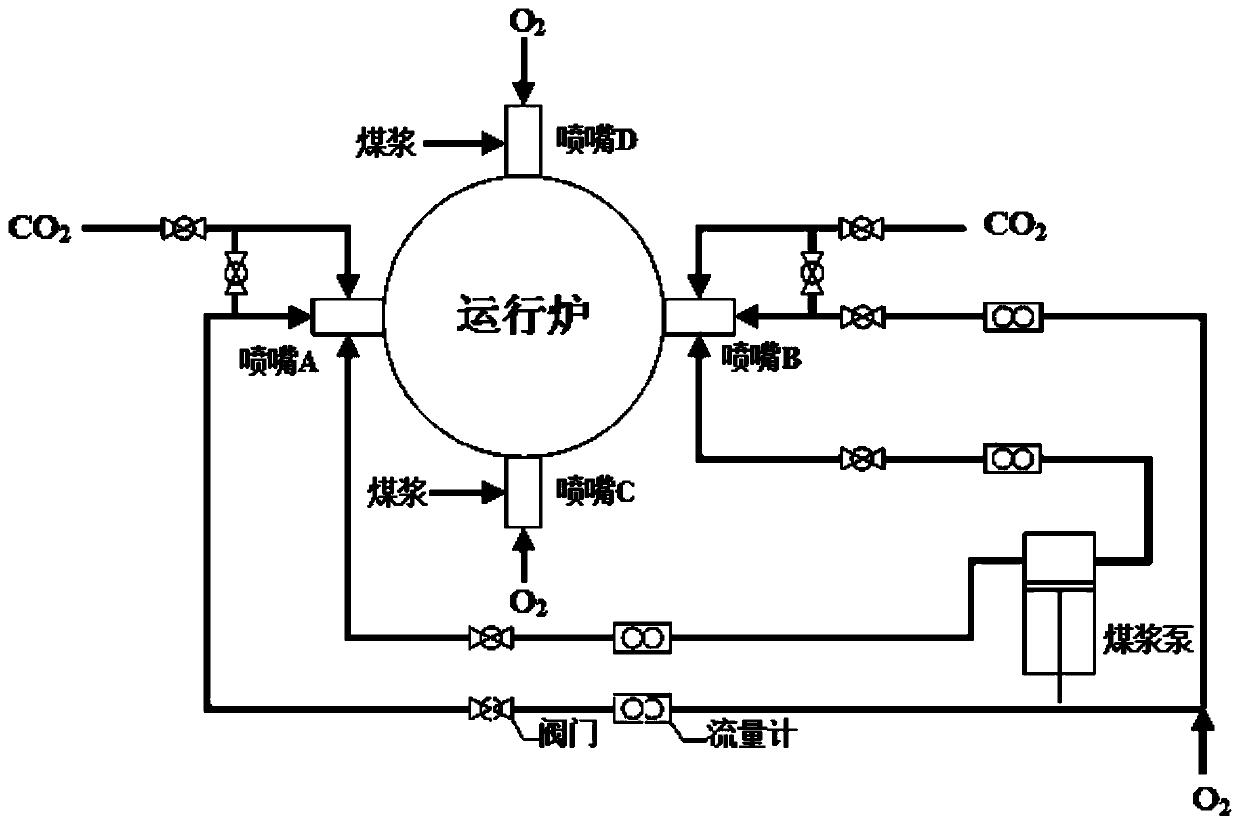

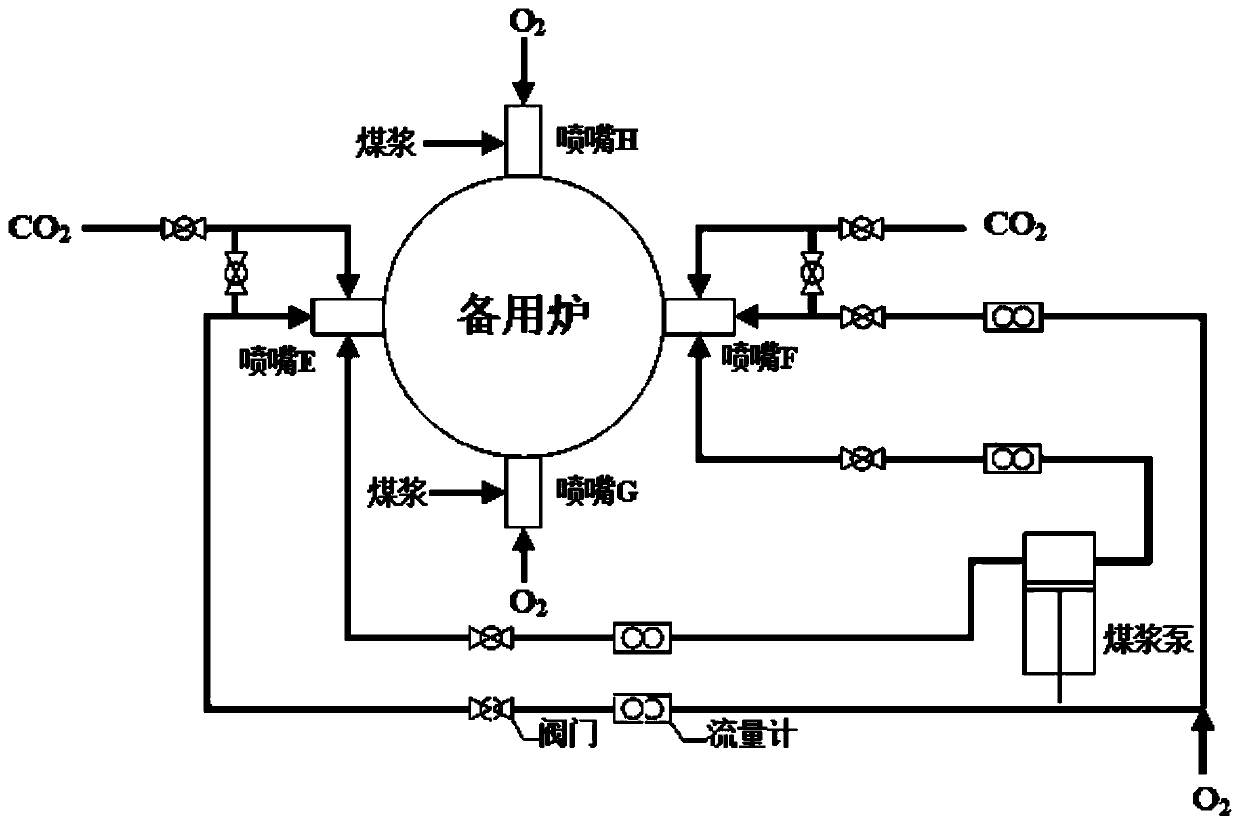

On-line switchover method of multi-nozzle gasifier

ActiveCN109135835BGuaranteed qualityThe atomization effect remains unchangedGranular/pulverulent flues gasificationCoal waterSyngas

Owner:EAST CHINA UNIV OF SCI & TECH

Step-by-step sulfuration method of sulfur tolerant shift catalyst

ActiveCN103657740BFast vulcanizationVulcanization efficiencyCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSulfidation

Owner:CHINA PETROLEUM & CHEM CORP

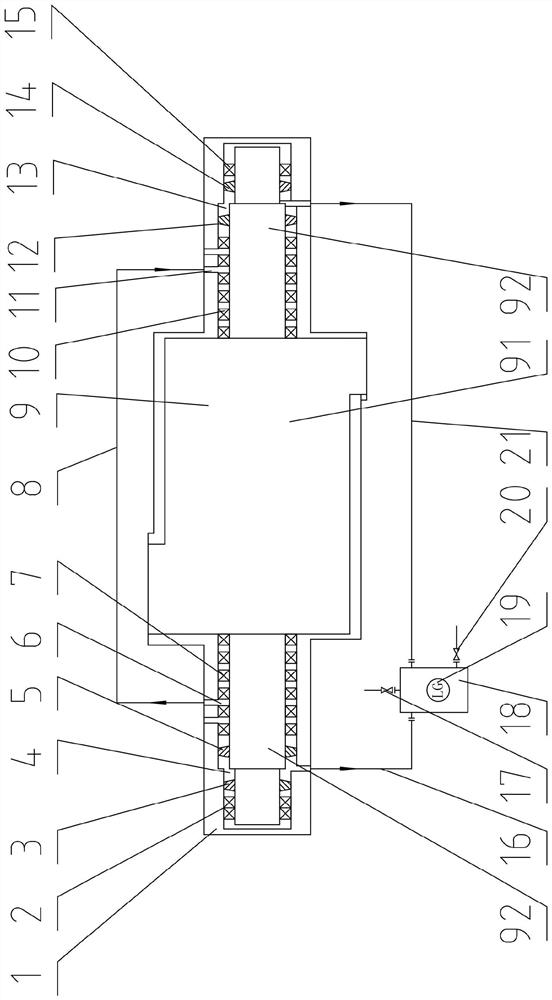

Shaft seal structure of threaded-rod steam compressor and monitoring system thereof

ActiveCN109404282ASimplified shaft seal structureReduce steam ventingSealing arrangement for pumpsMachines/enginesHigh pressureMonitoring system

The invention discloses a shaft seal structure of a threaded-rod steam compressor and a monitoring system thereof. The threaded-rod steam compressor comprises a shell, a threaded-rod rotor arranged inthe shell, the shaft seal structure, high-pressure-side bearings and a low-pressure-side bearing; the threaded-rod rotor comprises a threaded-rod compression part and two-side rotor shaft parts, thethreaded-rod compression part compresses steam, and the high-pressure-side bearings and the low-pressure-side bearing sleeve the two rotor shaft parts; the shaft seal structure is characterized by comprising a high-pressure-side shaft seal assembly and a low-pressure-side shaft seal assembly which are arranged on the rotor shaft parts and located between the high-pressure-side bearings and the threaded-rod compression part and the low-pressure-side bearing and the threaded-rod compression part, the high-pressure-side shaft seal assembly comprises high-pressure-side front-arranged seals, a high-pressure-side skeleton air seal and a high-pressure-side skeleton oil seal, and the low-pressure-side shaft seal assembly comprises low-pressure-side front-arranged seals, a low-pressure-side skeleton air seal and a low-pressure-side skeleton oil seal. The monitoring system monitors working states of the high-pressure-side skeleton air seal, the low-pressure-side skeleton air seal, the high-pressure-side skeleton oil seal and the low-pressure-side skeleton oil seal. The structure is simplified, the emptying amount of steam is decreased, injection of compressed air is canceled, and the cost issaved; monitoring of the shaft seal structure is achieved under the condition that the machine is not disassembled.

Owner:SUZHOU TORIN DRIVE EQUIP

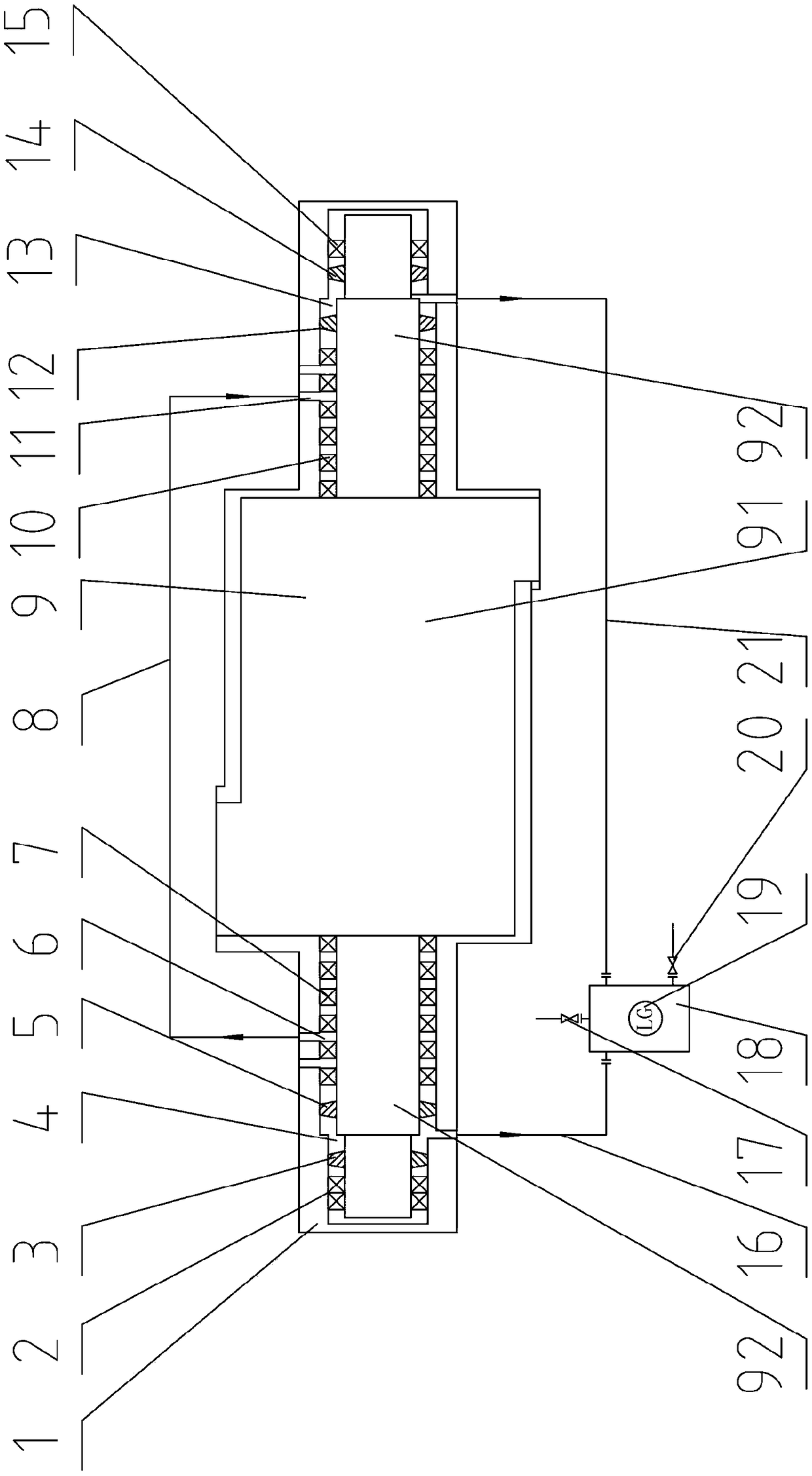

A two-stage temperature-raising reduction method for a coal-to-natural gas methanation catalyst

The invention belongs to the field of chemical industry and relates to a temperature-increasing reduction system, in particular to a two-stage temperature-increasing reduction method for a coal-to-natural gas methanation catalyst. In this method, more than six methanation reactors are divided into two sections, and two nitrogen cycles are respectively established, and the temperature is raised in sections, and the reduction is carried out in sections. The reduction uses a part of the raw material gas, that is, the synthesis gas, and uses the reducing gas in the raw material gas. h 2 , CO to reduce the catalyst; after the second stage reduction is completed, the temperature of the first stage methanation reactor that has been cooled is raised, and the difference between the temperature raised in the first stage and the temperature lowered in the second stage is ±50°C At this time, the overall temperature of all methanation reactors is raised until the start-up temperature requirements are met. The method can greatly shorten the heating time and reduction time; save a large amount of high-purity nitrogen; make the reduction process more flexible and easier to control, which is beneficial to more balanced and thorough reduction of methanation catalysts at all levels.

Owner:CNOOC GAS & POWER GRP +1

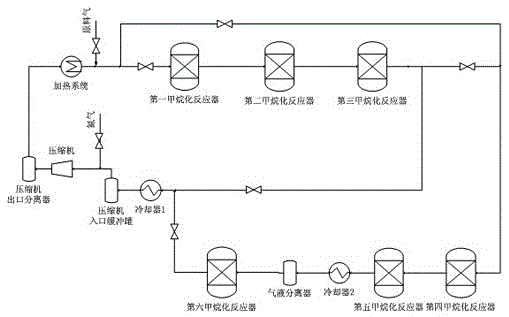

Method for coproducing or singly producing food grade carbon dioxide and industrial grade carbon dioxide by utilizing industrial waste gas

ActiveCN101538040BHigh recovery rateReduce ventingSolidificationLiquefactionIndustrial gasFood grade

The invention discloses a method for coproducing or singly producing food grade carbon dioxide and industrial grade carbon dioxide by utilizing industrial waste gas. The method takes industrial waste gas as raw material, and adopts two-step process of separation and purification; first, the feed gas is treated with primary purification, primary drying, primary condensation and primary extraction in sequence at 3.0 to 6.5 MPa by taking the quality of industrial products as an objective; and then part of or all the gas enters an industrial grade product storage tank, and the balance is decompressed to 1.8 to 3.5 MPa and treated with secondary purification, secondary drying, secondary condensation and liquefaction in sequence by taking the quality of food grade products as an objective; subsequently, secondary extraction is conducted to obtain the food grade carbon dioxide products. The invention adopts two-grade extraction process and a set of apparatus to coproduce or singly produce food grade carbon dioxide and industrial grade carbon dioxide, and can adjust the proportion between the food grade products and the industrial grade products in accordance with requirements; the invention also has the advantages of wide range of feed gas application, investment saving, low energy consumption, high recovery rate of carbon dioxide, excellent quality of products, safe and stable operation of the apparatus, and the like.

Owner:重庆川茂化工科技有限公司

A shaft seal structure of a screw steam compressor and its monitoring system

ActiveCN109404282BSimplified shaft seal structureReduce ventingSealing arrangement for pumpsMachines/enginesMonitoring systemStructural engineering

The invention discloses a shaft seal structure of a threaded-rod steam compressor and a monitoring system thereof. The threaded-rod steam compressor comprises a shell, a threaded-rod rotor arranged inthe shell, the shaft seal structure, high-pressure-side bearings and a low-pressure-side bearing; the threaded-rod rotor comprises a threaded-rod compression part and two-side rotor shaft parts, thethreaded-rod compression part compresses steam, and the high-pressure-side bearings and the low-pressure-side bearing sleeve the two rotor shaft parts; the shaft seal structure is characterized by comprising a high-pressure-side shaft seal assembly and a low-pressure-side shaft seal assembly which are arranged on the rotor shaft parts and located between the high-pressure-side bearings and the threaded-rod compression part and the low-pressure-side bearing and the threaded-rod compression part, the high-pressure-side shaft seal assembly comprises high-pressure-side front-arranged seals, a high-pressure-side skeleton air seal and a high-pressure-side skeleton oil seal, and the low-pressure-side shaft seal assembly comprises low-pressure-side front-arranged seals, a low-pressure-side skeleton air seal and a low-pressure-side skeleton oil seal. The monitoring system monitors working states of the high-pressure-side skeleton air seal, the low-pressure-side skeleton air seal, the high-pressure-side skeleton oil seal and the low-pressure-side skeleton oil seal. The structure is simplified, the emptying amount of steam is decreased, injection of compressed air is canceled, and the cost issaved; monitoring of the shaft seal structure is achieved under the condition that the machine is not disassembled.

Owner:SUZHOU TORIN DRIVE EQUIP

A kind of preparation method of high-impact copolymerized polypropylene

Belonging to the field of olefin polymerization in the petrochemical industry, the invention discloses a preparation method of high impact co-polypropylene. Specifically, carboxylate superfine powder particles are added into a vapor phase polymerization kettle to replace the existing LPN system. The preparation process is simple and practicable, compared with the prior art, the method provided by the invention can be applied to acquire a high impact ethylene co-polypropylene product, and also the method can maintain long-period stable operation of the production device.

Owner:SINOPEC YANGZI PETROCHEM +1

A pressure swing adsorption decarburization method and equipment capable of realizing adjustable alcohol-ammonia ratio

ActiveCN105169887BLess investmentAdapt to a wide rangeDispersed particle separationAlcoholTransformer

The invention discloses a pressure swing adsorption decarburization method and equipment capable of realizing an adjustable alcohol-ammonia ratio, and belongs to the field of pressure swing adsorption decarburization. The method takes the two-stage pressure swing adsorption process as the main line, sets up a secondary line between the first stage of the two-stage pressure swing adsorption process and the fine desulfurization mechanism, and controls whether the two-stage variable The two-stage pressure swing adsorption mechanism of the pressure adsorption process was incorporated into production. The equipment adjusts the methanol and synthetic ammonia process flow through measures such as short-term parking, replacement, and adjustment of corresponding lines, and a set of equipment realizes two process routes for alcohol ammonia production. Compared with the prior art, the pressure swing adsorption decarburization method and equipment of the present invention have the characteristics of easy realization, low equipment cost, wide product adaptability, etc., and have good popularization and application value.

Owner:山东晋控明水化工集团有限公司

A CO cryogenic separation system and method using nitrogen cycle

ActiveCN107473223BImprove efficiencyMeet pressure requirementsHydrogen separationCarbon monoxideDehydrogenationProcess engineering

The invention discloses a CO cryogenic separation system using nitrogen cycle. The CO cryogenic separation system comprises a main heat exchanger, a cryogenic separator, a hydrogen stripper, a demethanizer, a denitrogenation tower, a condensing evaporator and a cycle nitrogen compressor. The invention further discloses a CO cryogenic separation method using nitrogen cycle, wherein the CO cryogenic separation method comprises process steps of heat exchange, dehydrogenation, demethanation, denitrogenation, nitrogen compression refrigeration cycle and the like. The CO cryogenic separation system and method provided by the invention have beneficial effects that a nitrogen cycle compression and refrigeration process is adopted to fully play roles of high efficiency and low investment of a nitrogen compressor; the condensing evaporator is arranged to cleverly integrate the demethanizer and the denitrogenation tower, so as to greatly reduce power consumption of distillation; an operation pressure of a distillation tower is increased or a CO liquid pump is provided for replacing a CO compressor so as to meet pressure requirements of CO products; start-up and purification time of the device can be shortened and a venting amount at a start-up stage can be reduced; the system and the method has advantages of low energy consumption, fast start-up, investment saving and less emission, are in line with a general trend of energy conservation and consumption reduction, and have good economic and environmental protection benefits.

Owner:四川蜀道装备科技股份有限公司

Synthesis ammonia and methanol co-production method and device for improving methanol productivity

ActiveCN113416116AReduce nitrogen contentReduce loadOrganic compound preparationHydroxy compound preparationLow nitrogenPhysical chemistry

The invention relates to the technical field of synthesis ammonia and methanol co-production process and device, in particular to a synthesis ammonia and methanol co-production method and device for improving methanol productivity, the method introduces a stream of process gas subjected to a shift reaction, and the process gas is added into an inlet of a shift section non-shift gas system to form non-shift mixed gas with low nitrogen content as raw material gas for methanol synthesis. According to the method, the unconverted gas is subjected to a front hydrogen distribution mode, the rear hydrogen distribution amount is remarkably reduced, the nitrogen content in the front hydrogen distribution gas is low, so that the nitrogen content in the methanol synthesis raw material gas is reduced, the nitrogen content in the methanol synthesis circulating gas can be reduced, the emptying amount of the methanol synthesis purge gas is reduced, and the methanol yield is improved; meanwhile, the load of the shift gas washing tower at the low-temperature methanol washing section can be reduced, and the shift gas washing tower stably runs.

Owner:新疆心连心能源化工有限公司

Process and device for reclaiming hydrolysis desorption heat energy

ActiveCN101823984AReduce consumptionTake advantage ofUrea derivatives preparationOrganic compound preparationVapor–liquid separatorDesorption

The invention relates to a process and a device for reclaiming hydrolysis desorption heat energy. The process comprises the following steps: introducing gas from a hydrolysis desorption tower to a second preheater for a secondary ammonium carbamate solution for cooling, introducing to a gas-liquid separator, introducing a separated condensate to a reflux pump, and directly introducing the obtained gas to the middle section of a second-stage decomposing tower to carry out the backblowing on descending urine. The invention omits the water-cooling device in the original hydrolysis desorption flow, and lowers the consumption of circulating water; the hydrolysis desorption gas phase is directly introduced to the second ammonium carbamate preheater to make full use of the energy of the hydrolysis desorption gas phase, thereby raising the use ratio of the energy, and simultaneously reducing the gas release of the system; and the use of the technology can save about 0.1 ton of circulating water per ton of carbamide and save 10 kilograms of steam per ton of carbamide, thereby saving the cost.

Owner:LUXI IND EQUIP

Preparation method of high impact co-polypropylene

Belonging to the field of olefin polymerization in the petrochemical industry, the invention discloses a preparation method of high impact co-polypropylene. Specifically, carboxylate superfine powder particles are added into a vapor phase polymerization kettle to replace the existing LPN system. The preparation process is simple and practicable, compared with the prior art, the method provided by the invention can be applied to acquire a high impact ethylene co-polypropylene product, and also the method can maintain long-period stable operation of the production device.

Owner:SINOPEC YANGZI PETROCHEM +1

Condenser for recycling methylal from glyphosate tail gas

InactiveCN104930877ASlow flowExtended stayOrganic chemistryOrganic compound preparationGlyphosateRetention time

The invention provides a condenser for recycling methylal from glyphosate tail gas. The condenser comprises a pipe. A material inlet for conveying materials to be condensed is formed in the top end of the side wall of the pipe, a material outlet for conveying the materials to be condensed is formed in the bottom end of the side wall of the pipe, a material pipe for conveying the materials to be condensed is arranged in the pipe, the feeding end of the material pipe is communicated with the material inlet, the discharging end of the material pipe is communicated with the material outlet, and the top end of the pipe is provided with a cold water inlet for conveying condensate water. By the adoption of the methylal tail gas condenser, the flow speed of tail gas entering the condenser is low, the flow path is long, the retention time of the tail gas in the condenser is prolonged, the condensation effect can be effectively improved through an arranged condensation mechanism, the occupied space of the condenser can be saved, the condensation effect can be effectively improved, it is guaranteed that the emptying amount is extremely small, and the functions that the recovery amount is increased, consumption is reduced, and the environmental protection pressure is reduced are achieved.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

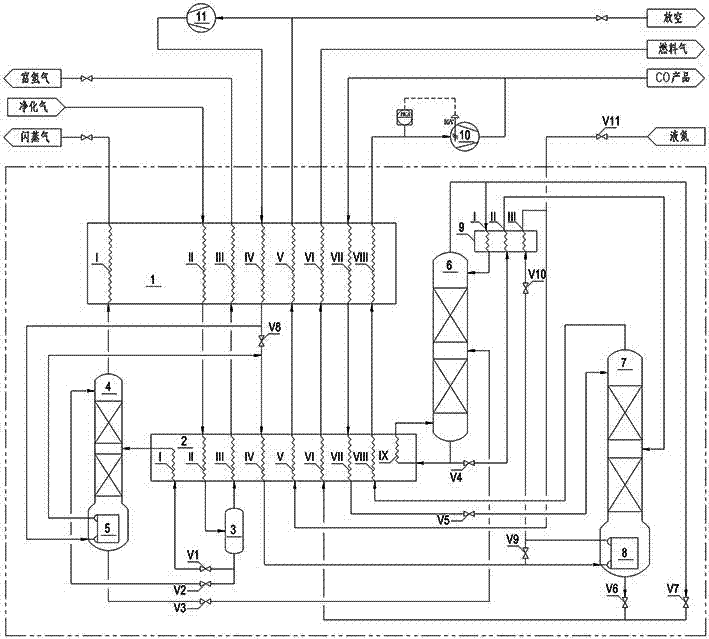

Low power consumption CO cryogenic separation system and separation method thereof

ActiveCN107490244AReduce exhaust pressureReduce power consumptionSolidificationLiquefactionStart timeGas compressor

The invention discloses a low power consumption CO cryogenic separation system. The low power consumption CO cryogenic separation system comprises a decarburizing gas purification unit, a cryogenic separation unit, a PSA hydrogen production unit, a parse gas compressor unit and a recycle compressor unit. The invention further discloses a separation method of the low power consumption CO cryogenic separation system. The separation method has the process steps of decarburizing gas purification, condensing and separating dehydrogenation, operation of a rectifying tower, operation of a recycle compressor, PSA hydrogen production and operation of a parse gas compressor. The low power consumption CO cryogenic separation system and the separation method of the low power consumption CO cryogenic separation system have the beneficial effects that hydrogen-rich tail gas or purifying gas is adopted to serve as resurgent gas, and it is guaranteed that parse gas of the PSA hydrogen production unit does not contain water or CO2; by independently arranging a parse gas heat exchanging channel and a low temperature separator, the power consumption of the parse gas compressor is substantially lowered; a nitrogen gas recycle compressor is adopted for replacing a CO recycle compressor low in efficiency, the power consumption of the recycle compressor is lowered, the starting time of the device can also be shortened, and the venting amount in the starting stage is reduced; and the energy consumption is low, starting is fast, investment is saved, the emission is little, and good economic benefits and environment protection benefits are achieved.

Owner:四川蜀道装备科技股份有限公司

A kind of cyclic rapid presulfurization of sulfur-tolerant shift catalyst and the method of segmented presulfurization by using it

ActiveCN103657741BShorten vulcanization timeShorten heating timeCatalyst activation/preparationSocial benefitsVulcanization

The invention relates to a segmental pre-vulcanizing method of a sulfur tolerant shift catalyst in a multi-segment conversion process, particularly relates to a method for rapidly pre-vulcanizing cobalt-molybdenum-series sulfur tolerant shift catalysts and belongs to the technical field of pretreatment of the sulfur tolerant shift catalyst. According to the method, aiming at the situations of the temperature raising and the slow vulcanizing speed caused due to insufficient vulcanizing conditions, a segmental vulcanizing method is utilized, namely the rapid pre-vulcanizing of a first-segment furnace is reinforced to raise the temperature of a subsequent second-segment furnace; first-segment vulcanizing conditions are reinforced to guarantee the vulcanization of the catalyst so as to realize the rapid, efficient and complete vulcanization, meanwhile, the temperature of a subsequent second-segment bed is raised by high-temperature vulcanized gas in a rapid vulcanizing process, and the subsequent working segments are similarly processed, so that the vulcanizing and temperature raising time is greatly shortened, and the vulcanizing cost is lowered; by utilizing a circular vulcanizing manner, the emptying quantity is few, the overtemperature is avoided, the vulcanizing process is convenient and safe, the pollution is light, and the method has remarkable economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com