A two-stage temperature-raising reduction method for a coal-to-natural gas methanation catalyst

A methanation catalyst and coal-to-natural gas technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of large amount of high-purity nitrogen, long heating and reduction time, and difficult control of reduction, so as to save high-purity nitrogen and shorten the Heating time, effect of improving reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

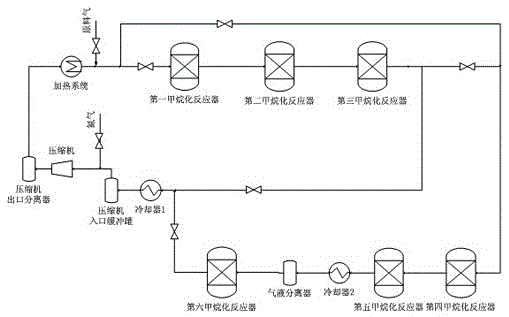

[0022] This coal-to-natural gas methanation catalyst two-stage temperature-raising reduction system contains six methanation reactors, namely the first methanation reactor, the second methanation reactor, the third methanation reactor, and the fourth methanation reactor , the fifth methanation reactor and the sixth methanation reactor, divide the six methanation reactors into two sections, and establish the first section of nitrogen circulation system for the first three methanation reactors, the system includes the first three methanation reactions device, compressor, heating system, nitrogen interface and feed gas interface, add high-purity nitrogen to the system to circulate, maintain the system pressure at about 0.6MPa, the heating system continuously provides heat for the circulating material, and the temperature rises at a rate of 30-50°C / h At about 450°C, a certain amount of raw material gas is introduced into the circulation system to control the CO+CO in the circulatio...

Embodiment 2

[0024] This coal-to-natural gas methanation catalyst two-stage temperature-raising reduction system contains seven methanation reactors, namely the first methanation reactor, the second methanation reactor, the third methanation reactor, and the fourth methanation reactor , the fifth methanation reactor, the sixth methanation reactor and the seventh methanation reactor, the seven methanation reactors are divided into two sections, and the first section nitrogen circulation system is established for the first three methanation reactors, the system Including the first three methanation reactors, compressors, heating system, nitrogen interface and feed gas interface, add high-purity nitrogen to the system to circulate, maintain the system pressure at about 0.6MPa, and the heating system continuously provides heat for the circulating materials, at 30-50 The heating rate of ℃ / h rises to about 450℃, and a certain amount of raw material gas is introduced into the circulation system to...

Embodiment 3

[0026] This coal-to-natural gas methanation catalyst two-stage temperature-raising reduction system contains six methanation reactors, namely the first methanation reactor, the second methanation reactor, the third methanation reactor, and the fourth methanation reactor , the fifth methanation reactor, and the sixth methanation reactor, the six methanation reactors are divided into two sections, and the first two methanation reactors are set up with a nitrogen circulation system in the first section, which includes the first two methanation reactions device, compressor, heating system, nitrogen interface and feed gas interface, add high-purity nitrogen to the system to circulate, maintain the system pressure at about 0.6MPa, the heating system continuously provides heat for the circulating material, and the temperature rises at a rate of 30-50°C / h At about 450°C, a certain amount of raw material gas is introduced into the circulation system to control the CO+CO in the circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com