Nitrogen-cycled methane washing system and method for separating CO and H2 in deep cooling manner

A technology of cryogenic separation and nitrogen circulation, which is applied in the field of nitrogen circulation methane washing system for cryogenic separation of CO and H2, can solve the problems of low efficiency of CO compressor and expander, large amount of venting in the start-up stage, and high pressure of circulating nitrogen, To achieve the effect of reducing the amount of venting, reducing the power consumption of rectification and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

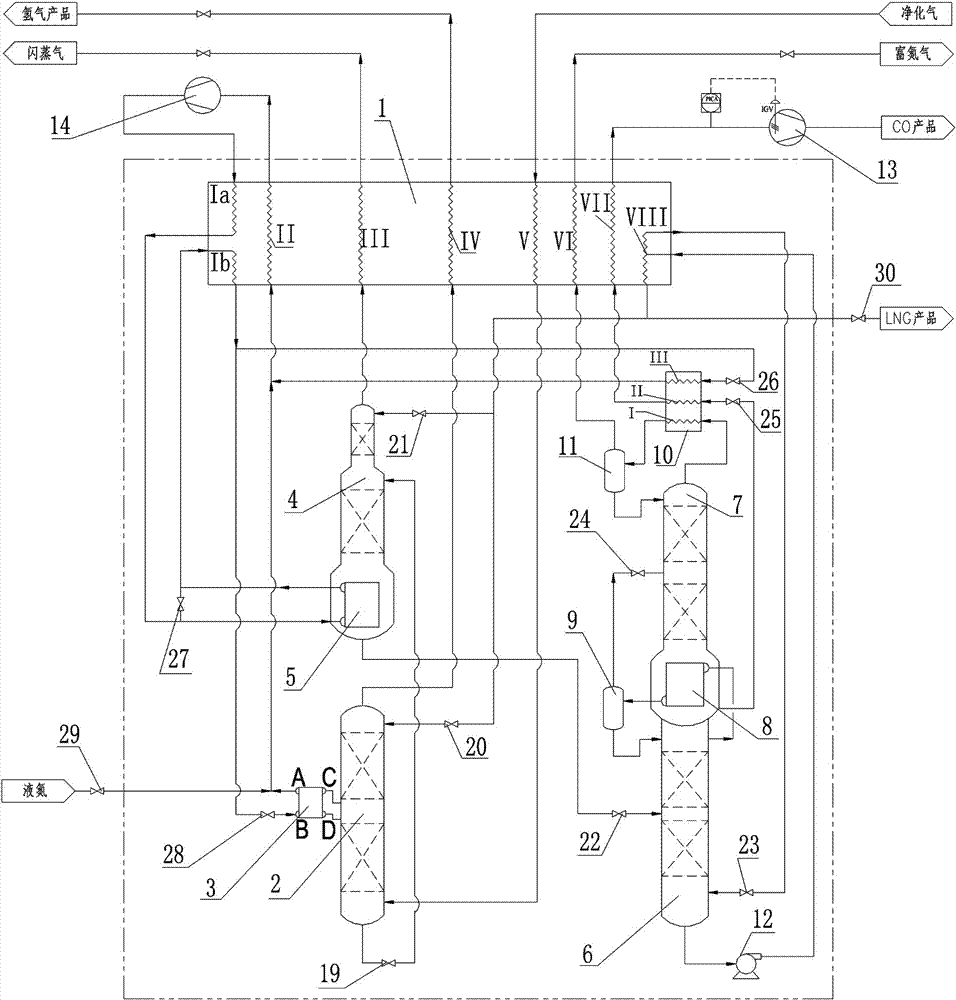

Embodiment 1

[0035] Embodiment one: if figure 1 As shown, a cryogenic separation of CO, H 2 The nitrogen cycle methane scrubbing system includes a main heat exchanger 1, a methane scrubber 2, a side condenser 3, a hydrogen stripper 4, a hydrogen stripper bottom evaporator 5, a demethanizer 6, and a nitrogen removal tower 7 , condensing evaporator 8, demethanizer overhead separator 9, denitrification tower overhead condenser 10, denitrification tower overhead separator 11, methane liquid pump 12, CO product compressor 13 and circulating nitrogen compressor 14, The main heat exchanger 1 is provided with a flow channel Ia, a flow channel Ib, a flow channel II, a flow channel III, a flow channel IV, a flow channel V, a flow channel VI, a flow channel VII and a flow channel VIII, and the denitrification tower The top condenser 10 is provided with flow passage I, flow passage II and flow passage III, the condensation evaporator 8 is arranged between the demethanizer 6 and the denitrification to...

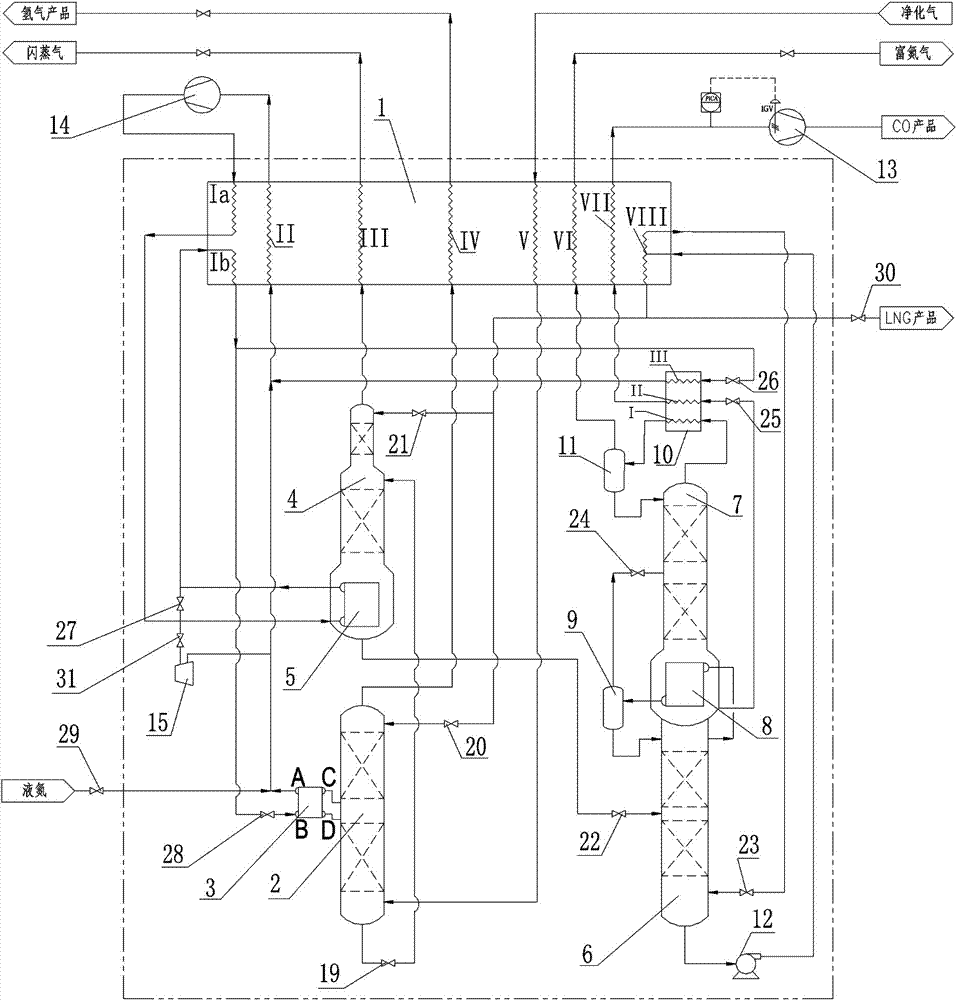

Embodiment 2

[0048] Embodiment two: if figure 2 As shown, the difference between the present embodiment and the first embodiment is that a flow of material is added at the outlet of the main heat exchanger 1 flow channel Ia, and is sent to the inlet of the turboexpander 15 after the valve M31, and the outlet of the turboexpander 15 The outlet is connected with the low-pressure nitrogen main pipe, and when the system is started or the cooling capacity is insufficient, the turbo expander 15 is used to produce cooling capacity.

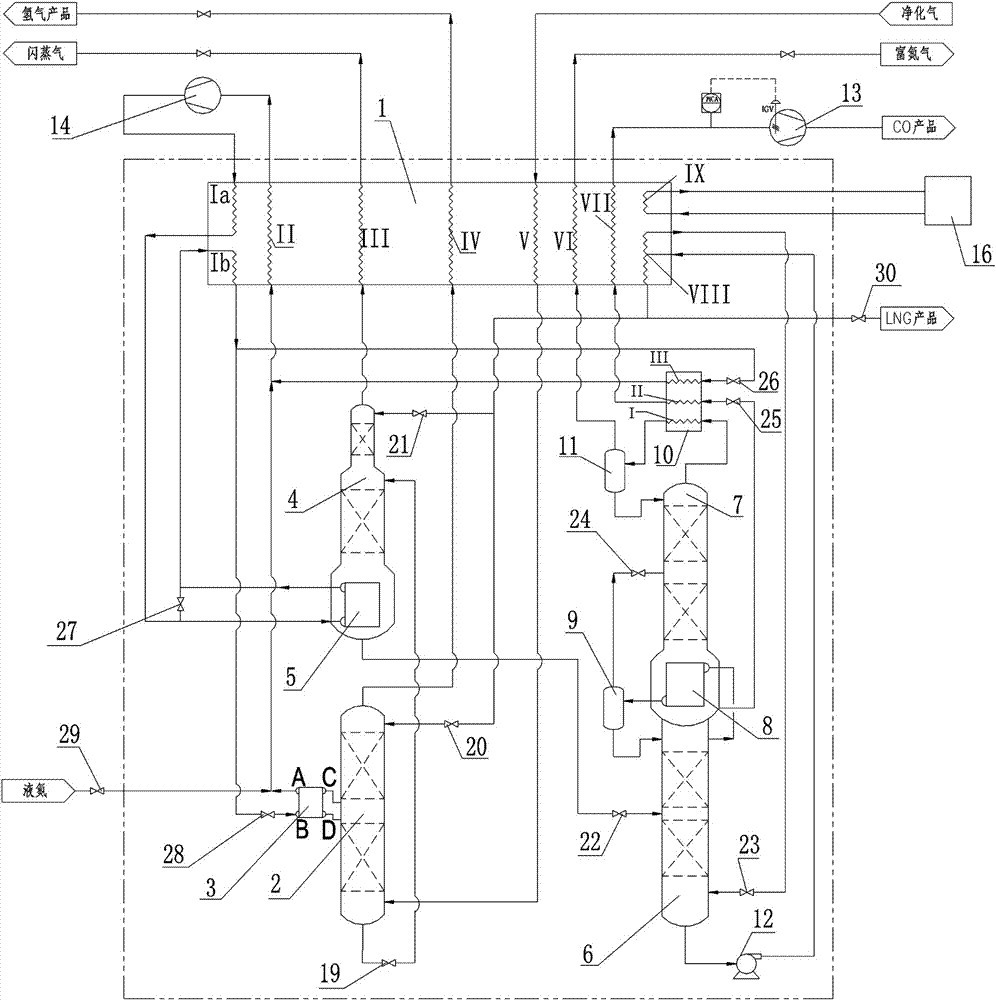

Embodiment 3

[0049]Embodiment three: as image 3 As shown, the difference between the present embodiment and the first embodiment is that the main heat exchanger 1 has a flow channel IX and is connected with the low-temperature pre-cooling unit 16 to provide cooling capacity for the system at a temperature of -40~40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com