A kind of preparation method of high-impact copolymerized polypropylene

A copolymerized polypropylene, high-impact technology, applied in the field of olefin polymerization, can solve the problems of reducing the partial pressure of the monomers effectively participating in the polymerization, increasing the discharge frequency of the gas phase kettle, and decreasing the polymerization production efficiency, so as to achieve the heat exchange efficiency without decreasing, avoiding the The effect of fluctuating device operation and reducing the amount of emptying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

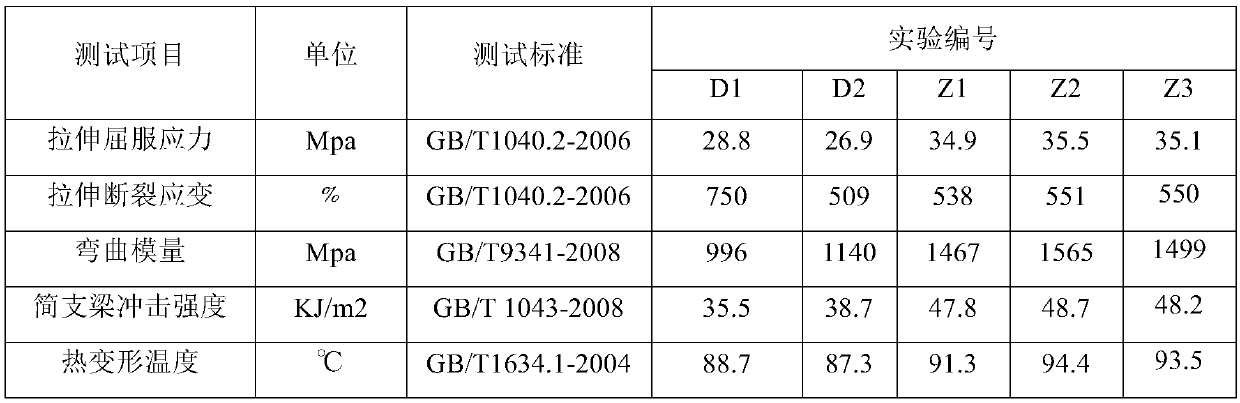

[0030] The analytical test method is as follows:

[0031] 1. Melt flow rate (MFR): Test method (standard) GB / T3862-2000, unit is g / 10min.

[0032] 2. Ethylene content: infrared spectroscopy, test method (standard) GB / T 6040-2002, analysis device, German Bruker IFS66 / S infrared spectrum analyzer.

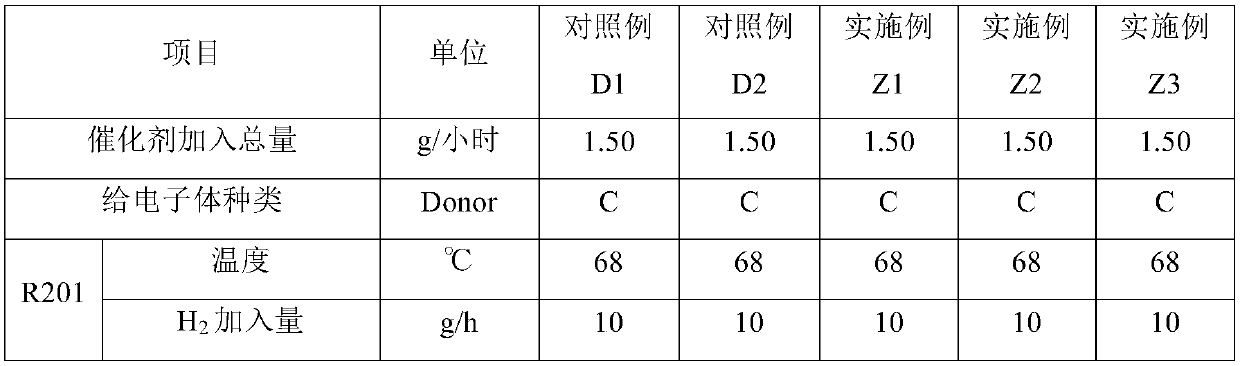

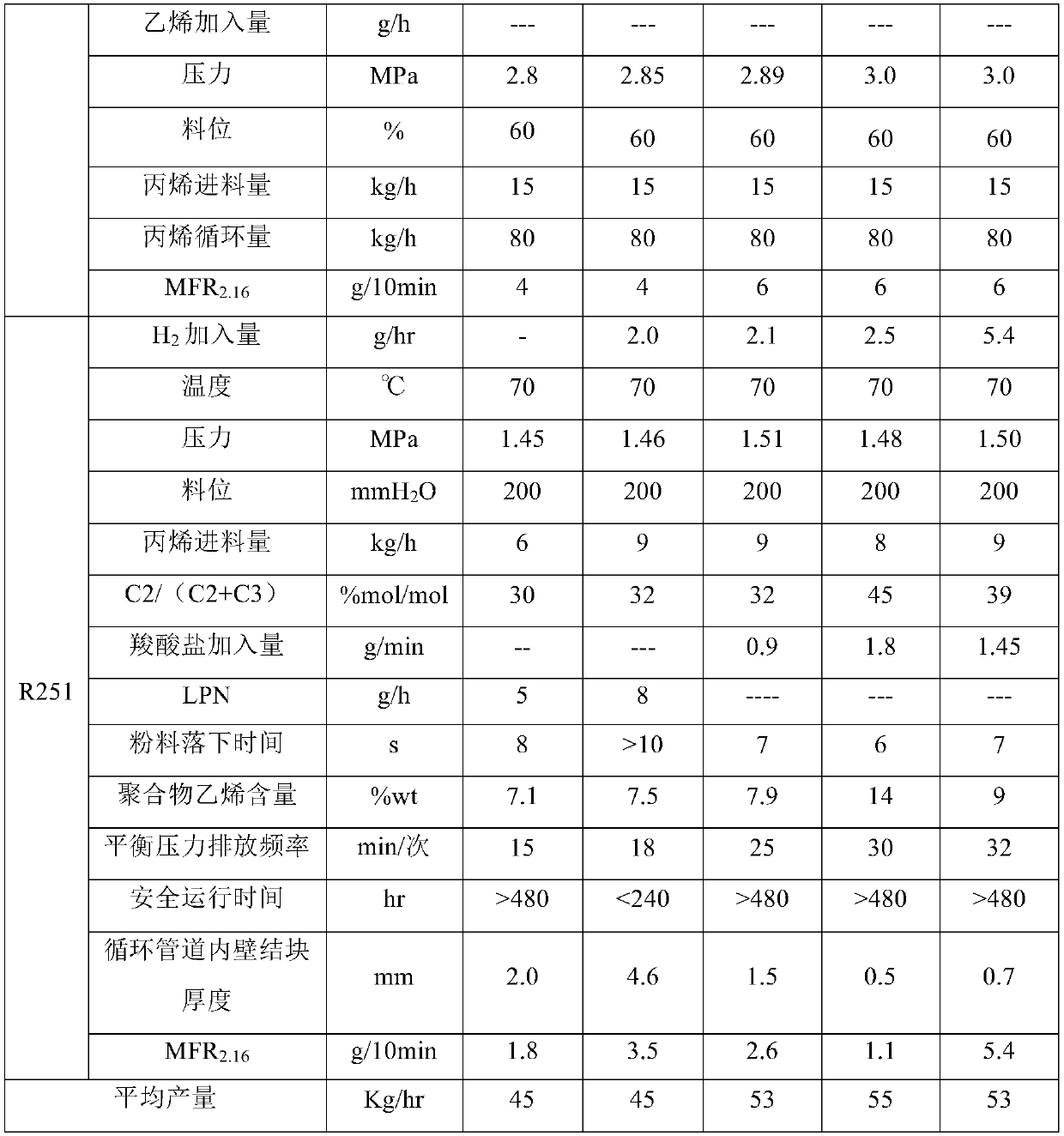

[0033] Continuous device test:

[0034] In this test plan, a pure gas-phase polymerization process in which two gas-phase polymerization tanks are connected in series is adopted, but other forms of combinations are also suitable for the present invention as long as they contain gas-phase reactors.

[0035]Carboxylate ultra-fine powder particles are selected from aluminum benzoate in this embodiment, and the injection area is at the outlet of the circulation pipeline. The specific form depends on the situation of the device, and the injection method is not limited. Pressurization is used to form a pressure difference injection Or by being configured with an inert component into an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com