Method for coproducing or singly producing food grade carbon dioxide and industrial grade carbon dioxide by utilizing industrial waste gas

A carbon dioxide and industrial waste gas technology, applied in chemical instruments and methods, chemical industry, inorganic chemistry, etc., can solve the problems of increased equipment manufacturing investment, large demand, and increased venting volume, and achieve reduced equipment investment and good product quality , the effect of small empty volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

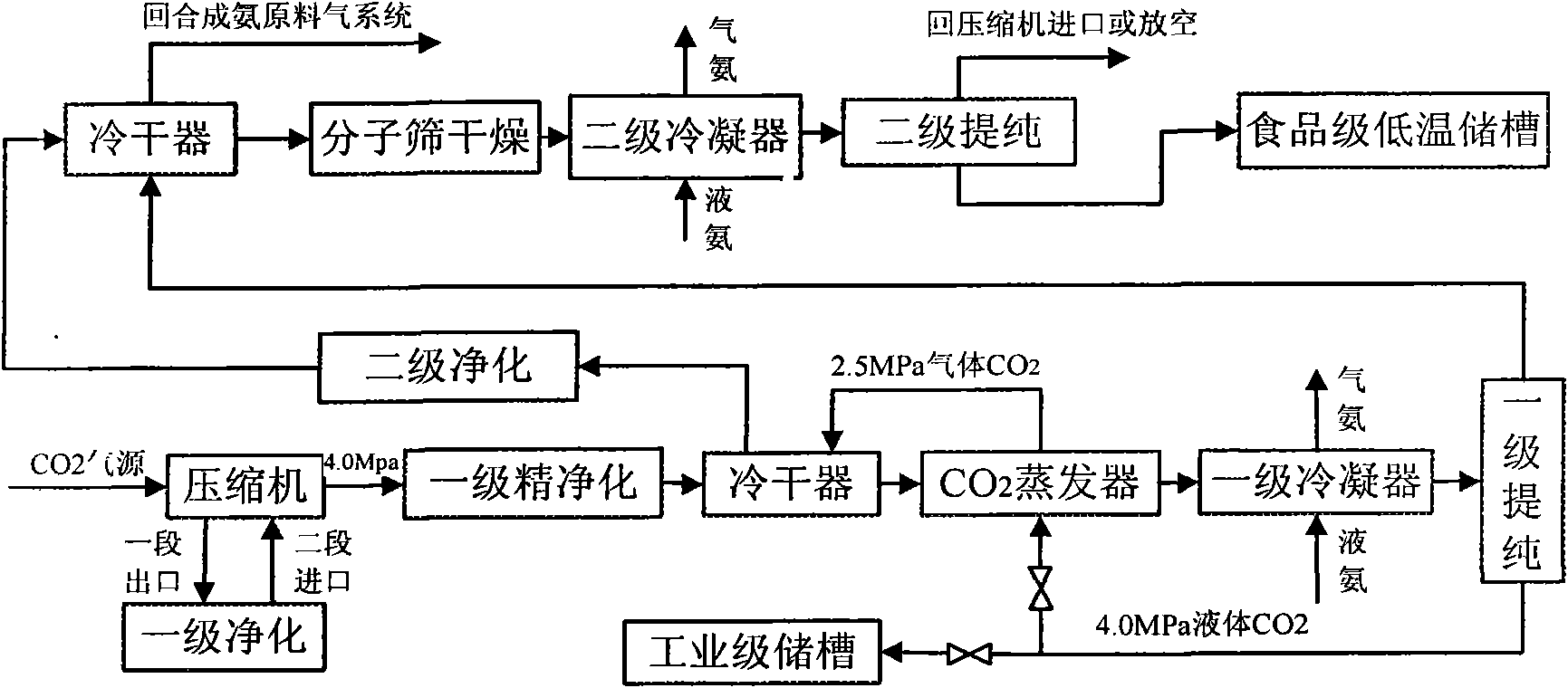

[0039] Pressure swing adsorption decarbonization and air release in a factory: total 3500Nm 3 / h, composed of CO 2 : 81.5%, H 2 : 6.2%, N 2 : 9%, O 2 : 1.5%, other impurities such as S and hydrocarbons: 1.8%. Its process is as figure 1 As shown: the exhaust gas is compressed to 4.0MPa by the second-stage compressor, and the exhaust gas is extracted from the compressor section with a pressure of ≤3.0MPa for pre-desulfurization, and the inorganic sulfur in the exhaust gas is removed, and then enters the compressor for compression. The waste gas from the compressor is dehydrolyzed, refined and desulfurized, and the organic sulfur and residual inorganic sulfur are removed, and then it enters the freeze dryer, and is dried to the industrial grade product standard (water content ≤ 20ppm) and then enters the CO 2 On the tube side of the evaporator, the heat exchange with the liquid carbon dioxide on the shell side is partially condensed, and the condensing temperature is about -...

Embodiment 2

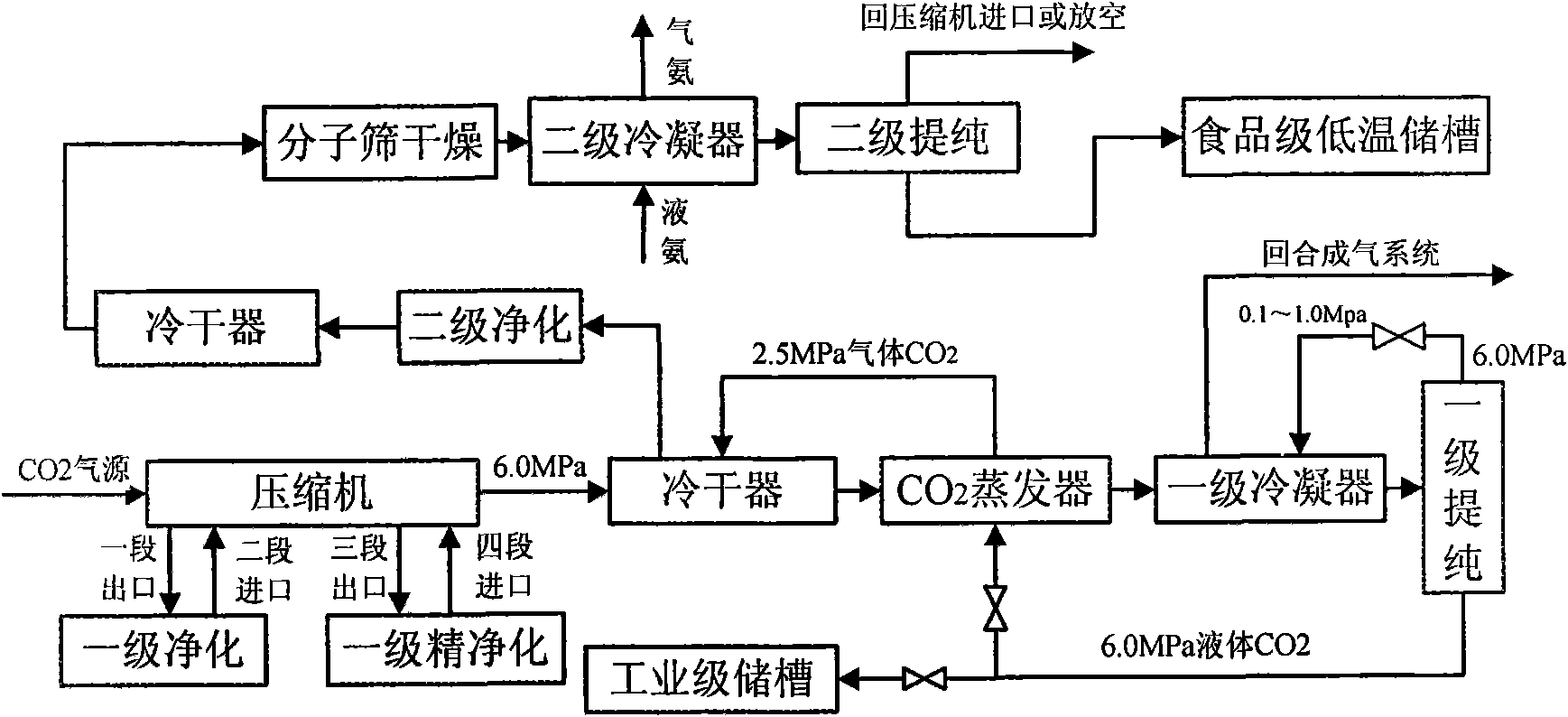

[0041] A factory vented exhaust gas, with a total amount of 5200Nm 3 / h, CO 2 The content is 62.3%, the rest is H 2 , N 2 , O 2 , hydrocarbons and trace amounts of impurities such as S. Its process is as figure 2 As shown in the figure, the exhaust gas is compressed to 6.0MPa by four-stage compression, extracted from the first-stage outlet for pre-desulfurization, and the inorganic sulfur in the exhaust gas is removed, and then enters the compressor from the second-stage inlet for compression, and then is extracted from the third-stage outlet for fine desulfurization. Remove organic sulfur and residual inorganic sulfur, and then enter the compressor from the fourth-stage inlet for compression. The exhaust gas with a pressure of 6.0MPa from the fourth stage of the compressor enters the cold dryer, and then enters the CO after drying. 2 On the tube side of the evaporator, the heat exchange with the liquid carbon dioxide on the shell side is partially condensed, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com