Technique for preparing cyclohexane by benzene hydrogenation using hydrogen produced by oxygen enrichment natural gas steam reforming method

A technology for hydrogenation of natural gas and benzene, applied in chemical instruments and methods, sustainable manufacturing/processing, chemical industry, etc., can solve problems such as air pollution, increase cost investment, and consume large amounts of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

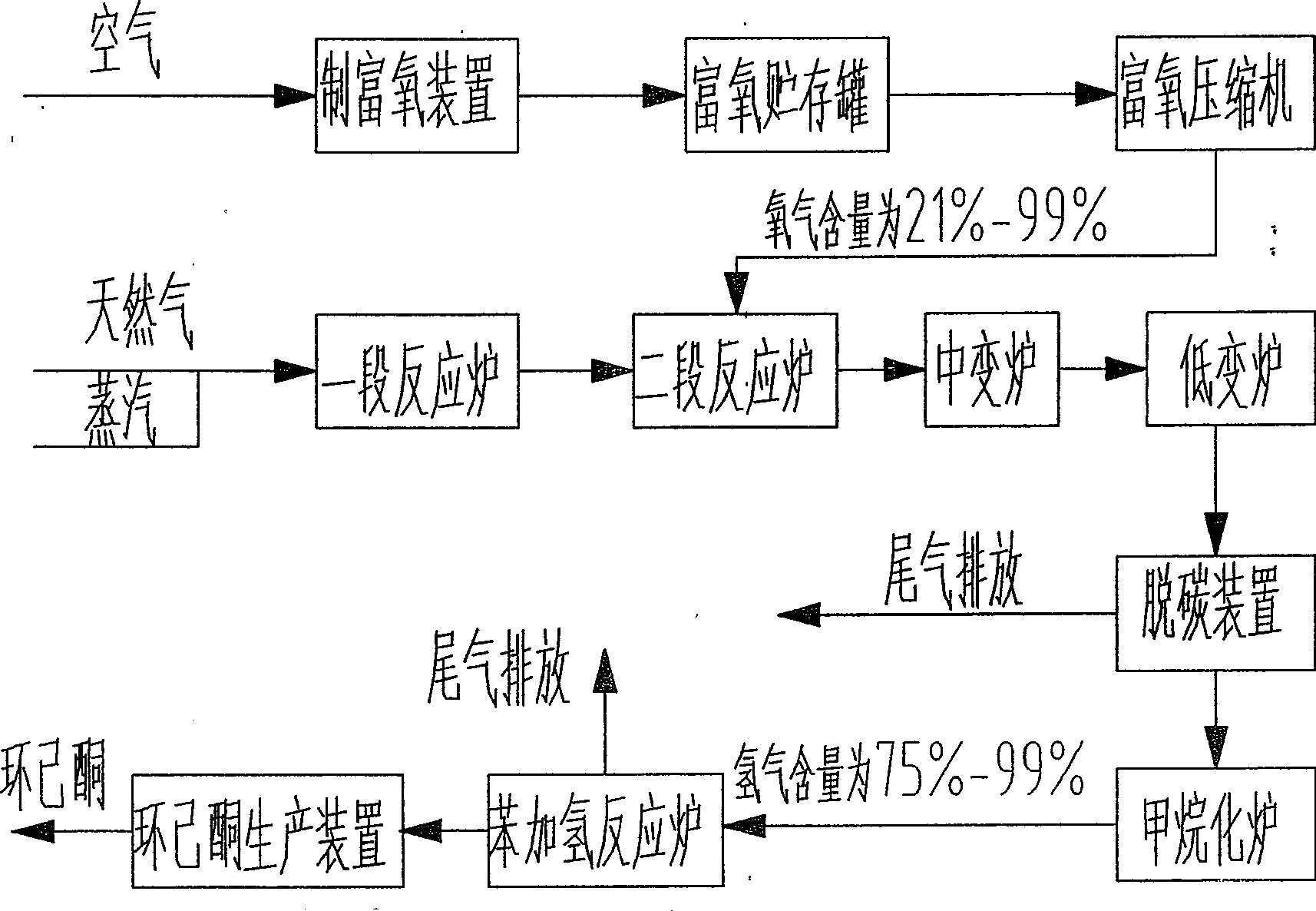

[0005] Refer to attached figure 1 In the cyclohexanone production unit, oxygen enrichment is used for natural gas steam reforming method to produce hydrogen as raw material hydrogen for benzene hydrogenation production as an example to provide the embodiment of the present invention:

[0006] The air passes through the oxygen-enriched production device to produce oxygen-enriched gas containing 75%-99% oxygen, enters the oxygen-enriched storage tank, and then enters the second-stage reformer through the oxygen-enriched compressor, where it is neutralized with natural gas and steam in the first stage The reformed gas undergoes an oxidation reaction, and the second-stage reformed gas undergoes medium-low transformation, decarburization, and methanation to produce hydrogen containing 75%-99% hydrogen, which is used in the hydrogenation reactor for the production of cyclohexanone for the reaction of benzene hydrogenation to cyclohexane Raw materials used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com