CO cryogenic separation system using double circulation and separation method thereof

A technology of cryogenic separation and separation method, which is applied in CO cryogenic separation system and its separation field, which can solve the problems of low efficiency of CO compressor and expander, large amount of venting at the start-up stage, and long purification time, etc., so as to reduce venting The effect of small amount, low investment cost, good economic benefits and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

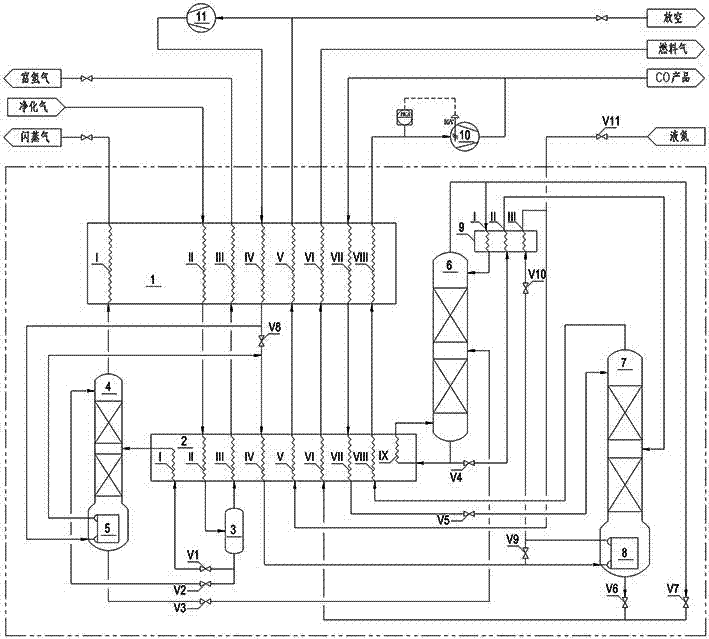

[0039] Embodiment one: if figure 1 As shown, a CO cryogenic separation system adopting double circulation, it includes main heat exchanger A1, main heat exchanger B2, low temperature separator 3, hydrogen stripper 4, hydrogen stripper bottom evaporator 5, Denitrification tower 6, demethanizer 7, demethanizer bottom evaporator 8, denitrification tower top condenser 9, CO compressor 10 and circulating nitrogen compressor 11; containing CO, hydrogen and a small amount of methane, nitrogen, The purified gas of argon is connected with the inlet of the main heat exchanger A1 flow channel II and the main heat exchanger B2 flow channel II in turn, and the outlet of the main heat exchanger B2 flow channel II is connected with the inlet of the low temperature separator 3, and the low temperature separator The gas phase outlet of 3 is connected with the inlet of the main heat exchanger B2 flow channel III and the main heat exchanger A1 flow channel III in turn, and the liquid phase outle...

Embodiment 2

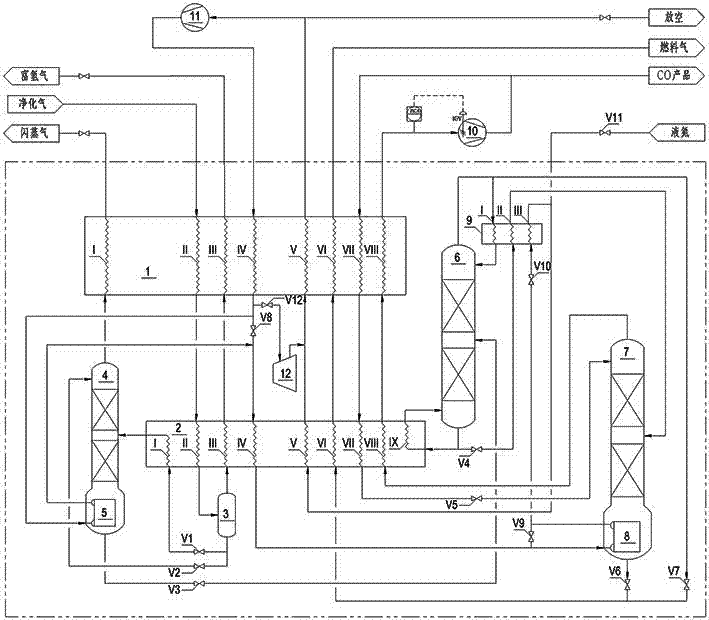

[0063] Embodiment 2: as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that a branch pipe is also provided on the passage connecting the decompression valve V8 to the outlet of the flow channel IV of the main heat exchanger A1, and the branch pipe is connected to the decompression valve V12 and then connected to On the inlet of the turboexpander 12, the outlet of the turboexpander 12 is connected to the pipe connecting the flow passage V of the main heat exchanger B2 and the flow passage V of the main heat exchanger A1. That is, a stream of stream is added at the outlet of medium-pressure nitrogen out of main heat exchanger A1 flow channel IV, and then sent to the inlet of turboexpander 12 after passing through decompression valve V12, and the outlet of turboexpander 12 is connected with the low-pressure nitrogen main pipe. When the device is started or the cooling capacity is insufficient, the turbo expander 12 is used to obtain the cooling cap...

Embodiment 3

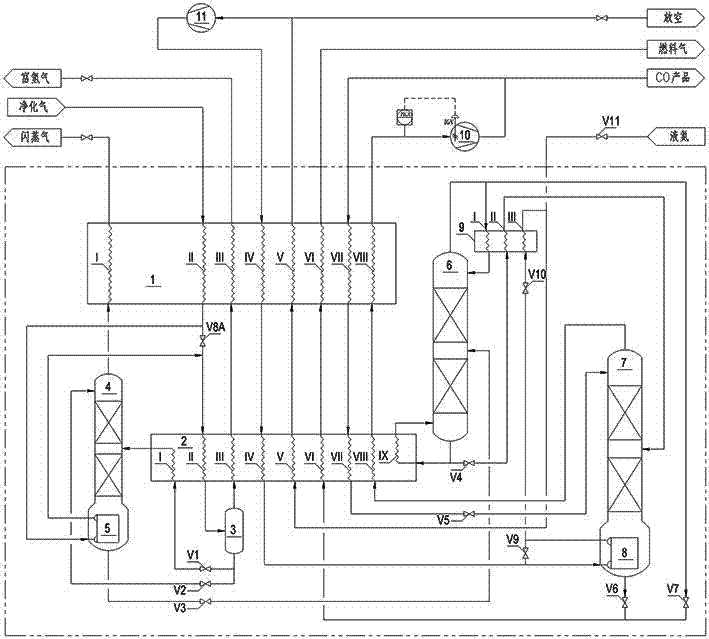

[0064] Embodiment 3: as image 3 As shown, the difference between this embodiment and Embodiment 1 is: the inlet node of the evaporator at the bottom of the hydrogen stripper and the outlet node of the evaporator at the bottom of the hydrogen stripper are arranged at the flow channel IIA of the main heat exchanger A1 and the main The pipeline connected to flow channel IIB of heat exchanger B2, and a pressure reducing valve V8A is set between the inlet node of hydrogen stripper bottom evaporator 5 and the outlet node of hydrogen stripper bottom evaporator 5, and the hydrogen stripper bottom evaporator The evaporator 5 inlet node is connected to the inlet of the hydrogen stripper bottom evaporator 5 through a pipeline, and the hydrogen stripper bottom evaporator 5 outlet node is connected to the hydrogen stripper bottom evaporator 5 outlet through a pipeline. That is, the heat source of the evaporator 5 at the bottom of the hydrogen stripper is purified gas, which can reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com