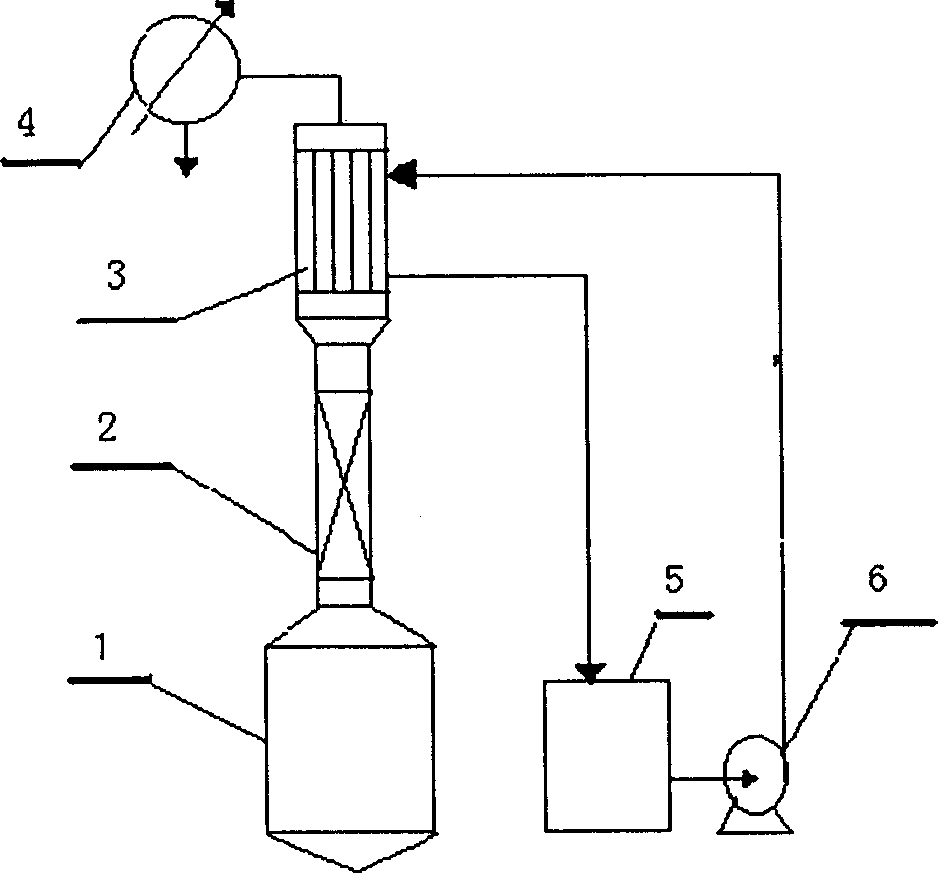

Flow-control-free intermittent fine distillation method and apparatus

A rectification and equipment technology, which is applied in the field of batch rectification and equipment without flow control, can solve the problems of increased investment in batch processing, high requirements for operation control, and increased separation difficulties, etc., to achieve convenient operation and control, reduce The volume of the tower kettle and the effect of reducing the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] For the recovery of 30% dilute alcohol, the diameter of the rectification section is 0.3 meters and the height is 2.0 meters; the height of the partial condensation section is 1.0 meters, and the diameter of the tubes is 25mm. It is 78 ℃, the volume concentration of recovered alcohol is maintained at 95%, and the recovery rate of alcohol reaches 98%, while the volume concentration of common intermittent rectification recovery alcohol is 93%, and the recovery rate of alcohol is about 94%.

Embodiment 2

[0022] Batch rectification is used to recover methanol from 50% methanol aqueous solution. The rectification section has a diameter of 0.2 meters and a height of 1.0 meters; the height of the partial condensation section is 0.6 meters, and the diameter of the tubes is 20mm. The temperature of the hot water in the constant temperature bath is in the range of 60 to 62 ℃, the control tower top temperature is 64.5 ℃, the concentration of product methanol is maintained at 99%, and the yield is about 96%, while the concentration of ordinary batch distillation methanol product is maintained at 97%, and the yield is about 93%.

Embodiment 3

[0024] Batch rectification experimental device for the separation of ethanol-ethyl lactate system. The partial condensation rectification section is a 24-port, 400mm straight condenser tube. Control tower top temperature to be 78 ℃, the concentration of ethanol of tower top product is 98%, the concentration of tower bottom product ethyl lactate is 99%, and the concentration of common intermittent rectification ethyl lactate product is about 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com